Investigation of Extensional Flow Behavior of Polyethylene Melts through Birefringence by using Extrusion Cross-slot Die

Academic Journal of Polymer Science - Juniper Publishers

Abstract

Flow parameters of polymers melt under steady state condition in shear are required to assess flow behaviour of the molten material in the die or downstream operations. Very often this is not sufficient to have a full understanding of the polymer processability, and additional information of flow response in extension is also needed. In this paper, the extensional properties of two molten polyethylene have been investigated by measuring stress response when a high extensional deformation is applied in a cross-slot die. Flow induced birefringence analysis and stress-optical rule are applied to determine rheological properties. Two polyethylene’s with similar rheology in shear but different molecular structure (HDPE and LLDPE) are analysed. Very interestingly, this approach appears capable of capturing differences in extensional flow that are not detectable using other conventional analytical methods.

Keywords: Flow Birefringence; Stress Optical Rule; Extensional Flow; Extensional Rheometry; Viscoelasticity

Introduction

Viscoelastic responses in shear and extensional regime of polymer melts are of paramount importance as they dominate most of the processing of polymers in the molten state [1]. Therefore, in industrial field, knowledge of rheology of polymers plays a central role in designing and understanding many processing operations: extrusion, blow molding, cast-blow extrusion, injection molding [2,3]. Specifically, extensional flow al high strain rate (ε ̇) is easily encountered in many industrial processes and there is increasing demand for generating more information about it [4]. It is usually more difficult to characterise properties of extensional flow than for simple shear. This kind of flow is commonly achieved with rheometers designed to uniaxially stretch the material. They typically include filament stretching [5] and dual wind-up stretching device [6]. However, true steady-state flow conditions are quite often difficult or impossible to reach because unlimited deformation is theoretically required [7], whereas elongational test is prone to sample inhomogeneity (due to localized necking) and rupture [8,9]. Gravity and non-isothermal condition on the sample, if the test is not carried out in climatic chamber or in thermostatic fluid, conspire to add limitation with these approaches. In many cases, when materials need to be tested at relative high temperature and broad strain rate close to effective industrial processing conditions, conventional lab-scale approaches in extensional flow with existing stretching rheometers are not capable to fully provide the required information. Low melt strength or sagging of molten materials promote premature deformation of the specimen, forcing to carrying out test at lower temperatures and it is not representative of real process conditions. This can limit the usage of conventional devices and methods. Therefore, there are relatively few data available for extensional flow [10] and especially for low viscosity molten polymers, measurements are very often overlooked and sometimes results are an over-simplification of real behavior.

For these reasons, full characterization of true steady state value for extensional stress response over a broad range strain rates is still an open topic in the field of polymer melts. In this scenario, cross-slot die, and rheo-optical approach appear to be a valid tool to get insight into rheology of complex flow and mimic and capture more closely extensional flow typically encountered in industrial operations [11,12]. Specifically, rheo-optical method offers potential to explore and evaluate the spatial-temporal evolution of the stress response of polymer melts [13]. It is an elegant and non-invasive way to generate extensional flow in controlled environment and confined geometries (the cross-slot die), it is well suited for polymer melts with poor melt strength, and/or non-homogeneous deformation at relatively high Henky strain or in case of not-achievement of a robust steady state [14]. Lastly, extensional flow can be sustained indefinitely in long run. This is possible through the connection of flow cell to a couple of extruders that provide a continuous feed of molten polymers up to relatively high flow rate. Thanks to the execution of the test in confined geometries, the method is insensitive to problems of melt yielding and high fluidity that, on the contrary, could make problematic the use of current rheometers operating in “not confined” environment. The specific geometry of the crossslot used in these experiments provides, for material transiting close to the stagnation point, high planar extensional flow that propagates along the entire plane of symmetry toward the outlet, which results in high level of extensional rate. Flow induced birefringence measurement (FIB) is used to evaluate interaction of the light with the polymer melt flow. Moreover the birefringence property is related to the stress distribution, polymer chains orientation and stretching with respect to stress directions.

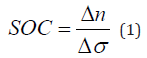

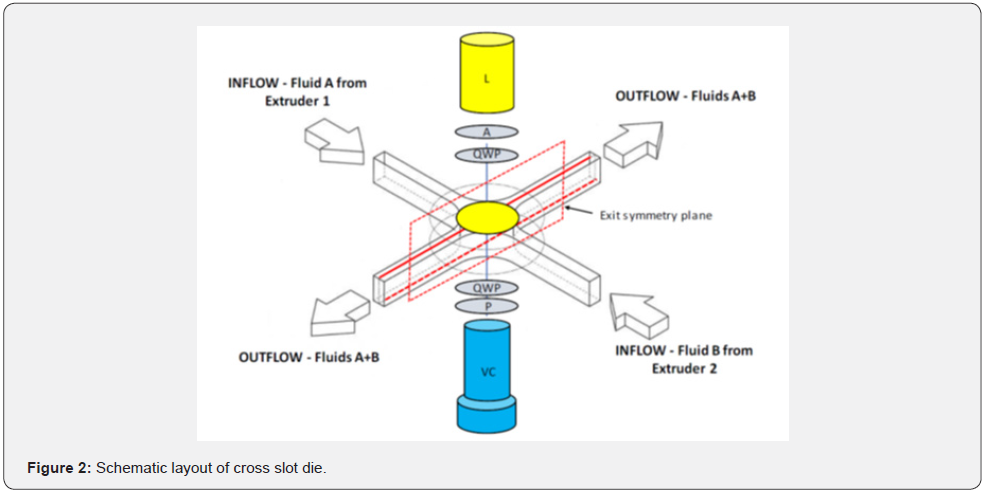

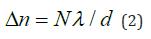

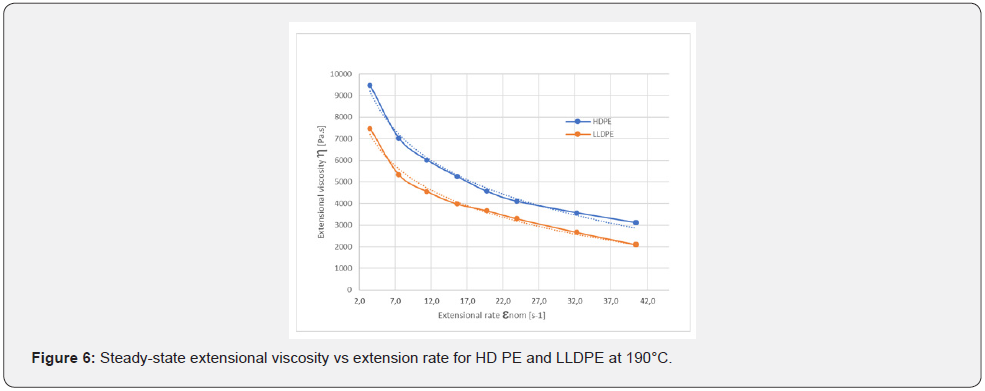

Stresses in the melt stream were evaluated and quantified from flow-induced-birefringence (FIB) pattern along the centerline using the stress optical rule (SOR). It is well known that there exists, under a wide variety of conditions, a constant in the ratio of birefringence n and stress σ and is expressed as:

Where SOC is the stress optical coefficient for the polymers under analysis. It is given in unit of Pa-1. For the work presented in this paper a SOC of 1,80 x 10-9 Pa-1 is used for HDPE and LLDPE, which is in good agreement with the range given in literature for PE from 1,2 to 2,4 x10-9 Pa-1 [15,16]. Stress-optical rule has been found to remain linear in a wide stress range [17] and SOC weakly dependent on temperature [17,18]. The main goal of this paper is to investigate if melt flow induced stress birefringence can capture and well allow distinction of the behavior in extensional flow of the two polymers, otherwise not distinguishable with conventional rheological techniques. At the same time, we want to verify how sensitive the method is to capture differences in behaviour due to branching.

Materials and Experimental Setups

Materials

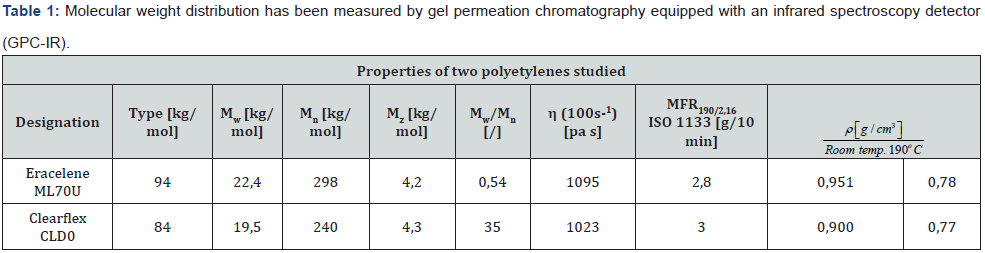

Materials used in this paper are a linear HDPE (Eraclene ML70U) and LLPDE (Clearflex CLD0) produced by Versalis, both with a very similar melt flow index. The first one is designed for extrusion application, whereas the second one is more suitable for injection moulding and film processes. They have very different degree of branching but despite this different molecular structure and application, still exhibit similar shear viscosity (Table 1).

Material Characterization in Shear Flow

The viscoelastic behaviour of two polyethylene samples has been evaluated in shear capillary experiment and by dynamic analysis. Results are reported in Table 1 and in Figure 1 (Master Curves). The grades have been selected because have very similar shear viscosity and master curve but very different degree of branching. It must be pointed out that both PE’s grades, neither elongational viscosity test nor fiber melt spinning measurements can be performed, due to the very low melt strength and sagging of the polymers at high temperature. Oscillating shear capillary rheometry (OSCAR) [19] has been also used to assess the complex rheology of LLDPE and of HDPE. The behaviour of the elastic modulus was measured at 190 °C for a shear cycle of period p=180s and amplitude  . The elastic shear modulus reaches almost the same low shear rate value of 0.12 MPa for both PE but shows a plateau only for the HDPE up to 200 s-1 while for the LLDPE it keeps constantly decreasing within the same range of shear. It is also important to report that the shear viscosity modulus V(γ ̇) for both samples is perfectly superimposable.The elastic shear modulus behaviour can give some explanation to the industrial evidence on why the LLDPE is not suitable for extrusion production due to the inconsistency of its melt strength, also providing an explanation on why those polymers are not suitable for the same transformation process. Unfortunately, this approach requires a dedicated instrument with a very time-consuming experimental approach. In this work we have investigated the extensional viscosity at high ε ̇ rate of strain to fully access the rheological response of both material in many industrial processes.

. The elastic shear modulus reaches almost the same low shear rate value of 0.12 MPa for both PE but shows a plateau only for the HDPE up to 200 s-1 while for the LLDPE it keeps constantly decreasing within the same range of shear. It is also important to report that the shear viscosity modulus V(γ ̇) for both samples is perfectly superimposable.The elastic shear modulus behaviour can give some explanation to the industrial evidence on why the LLDPE is not suitable for extrusion production due to the inconsistency of its melt strength, also providing an explanation on why those polymers are not suitable for the same transformation process. Unfortunately, this approach requires a dedicated instrument with a very time-consuming experimental approach. In this work we have investigated the extensional viscosity at high ε ̇ rate of strain to fully access the rheological response of both material in many industrial processes.

Experimental Set Up

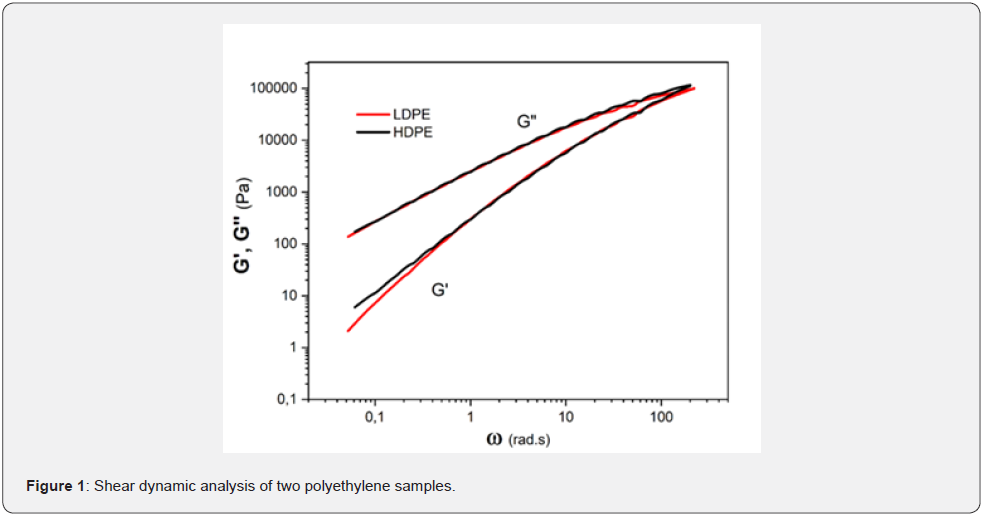

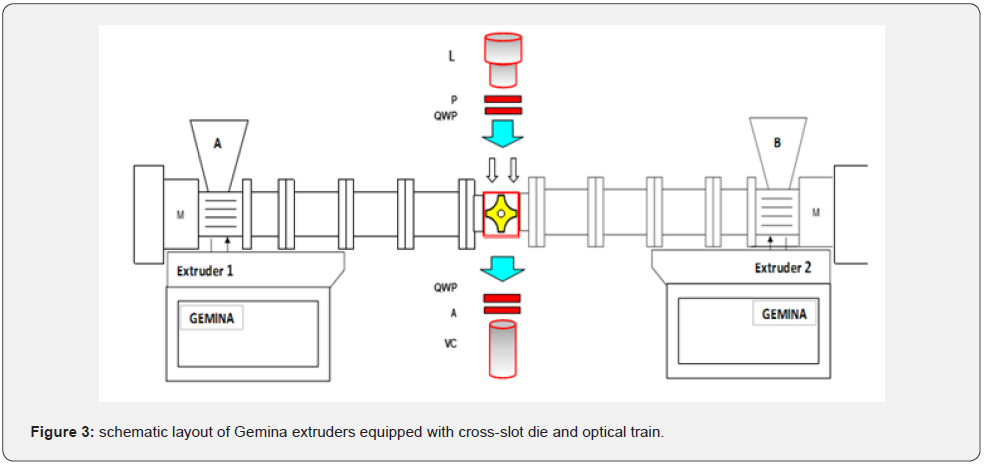

Equipment used for flow induced birefringence (from now on named as FIB) experiments is called “GEMINA”. It was designed and manufactured by Isotattica [20]. It basically consists of a couple of extruders and a patent pending cross-slot die including an optical bench for flow visualization.

Single screw extruders

To obtain a continuous flow of molten polymer to be delivered to the cross-slot die, the two independent-controlled extruders are coupled with the cross-slot apparatus. Each extruder is equipped with a 30 mm barrel/screw diameter and a L/D ratio of 25. Each of them is heated by three electrically powered zones on the barrel, a fourth one on the flange and a fifth one on die. It is powered by a 4 kW electric motor with a drive gear and electronic speed controller. Experiments are carried out at three different melt temperatures: 160, 190 and 220 °C, the extents of this range has been chosen in order to reproduce typical situations of use in machining processes. Pellets of polymers are feed in the hopper and molten polymer is transported along the extruder into the die. Setting temperatures from hopper to the die are selected in such way to get an effective temperature of the molten polymers as indicated above. Flow visualization experiments were performed after waiting for a certain time (15 min) for extruder parameters stabilization. Typical data collected for each run are as follows: flow rate, video and picture capturing for subsequent sequencing and processing via FIB. The range of flow rate used for experiments is from 20 cm3/min up to 290 cm3/min (i.e. from 16 s-1 to 225 s-1 in terms of apparent shear rates near inlet flow passageway).

Cross-slot die

A modular cross-slot die is fitted at the extruders exit from when the molten polymers flow. The cross-slot geometry provides four perpendicular, intersecting coplanar channels (width 4 mm, channel depth 8 mm), rounded at intersection point (Figure 2). The flow involves two opposed inlet streams which lies on the same axis meeting at a planar stagnation point and then exit orthogonally. It has a pair of stress-free transparent viewing windows (borosilicate glass) that allows a light beam to pass through the midsection of flow field and orthogonal analyzer before being captured using a digital video camera. The entire die is heated with electric heaters deeply inserted in the die, then connected with two independent temperature probe and controlled by the two zones 5B of the extruder panel control. The die is also equipped with 4 thread holes, in the passageway between adapters and cross die, for inserting melt pressure transducer or temperature probe (flush mounted). The two molten polymers are extruded with controlled flow rate and temperature in opposite directions towards the centre along the opposing collinear flow channels. By impinging these two fluids, flow induced stress birefringence is generated, allowing visualization and mapping of stress fringes, that correspond to a locus of constant value of principal stress differences PSD. Largestrain extensional flow deformations, preferred alignments and stagnation flow are generated along the inlet-outlet symmetry plane of the collinear channels and then analysed via flow-induced birefringence.

Optical bench

The flow birefringence measurements are performed using an optical bench as shown schematically in Figure 3. From top to the bottom, it consists of light source (white light), polarizer, two quarter wave plate (the cross-slot die is placed between them), analyser, extension tube with camera lens, and digital video camera. Firstly, the light beam passes the polarizer and quarter wave pate, enter through glass windows the melt stream which rotates its polarization state, then exit through the other glass window, quarter wave plate and analyser before reaching video camera. With this arrangement polarization of light is circular (circular polariscope in dark or bright field), isoclinic extinction bands (loci of points where principal stresses directions are constant) are not visible, leaving only stress-related isochromatic fringes (loci of points where the difference of principal normal stresses is constant). The optical parts are designed for fast assembly on a stand, are mechanically independent and moveable in all three dimensions for precise tuning of each component. Additionally, said stand, after competition of runs, can be moved away from die housing and extruders. With white light, coloured bands are observed, they are called “isochromatic fringes”. Firstly, fringe tracking and fringe order assignment are done. Considering that each isochromatic fringe with same colour carries the same light retardation and corresponds to a constant value of principal stress difference, the latter can be quantified through the stress optical rule.

The most important relation that allows us to calculate the PSD is given below:

Here N is the fringe order, l is the wavelength of light, d the channel depth. Combining stress optical rule (Equation 1) and Equation 2 it is possible to calculate the PSD by determining birefringence in molten flow on each isochromatic fringe.

Results and Discussion

Elongational flow/FIB

In the symmetry plane inlet-outlet along the centreline, at steady state regime, polymer flow experiences a constant extension rate ε̇. It can be estimated by the formula:

Where Vavg is the average velocity in the passageway and w the channel width. In this area flow approaches fully developed planar stretching flow. The steady state elongational viscosity is calculated from tensile stress (σstd is the PSD-principal stress difference between X-extensional and y-compressional axes, determined by FIB analysis) and the steady state strain rate ε̇ (Equation 4):

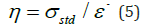

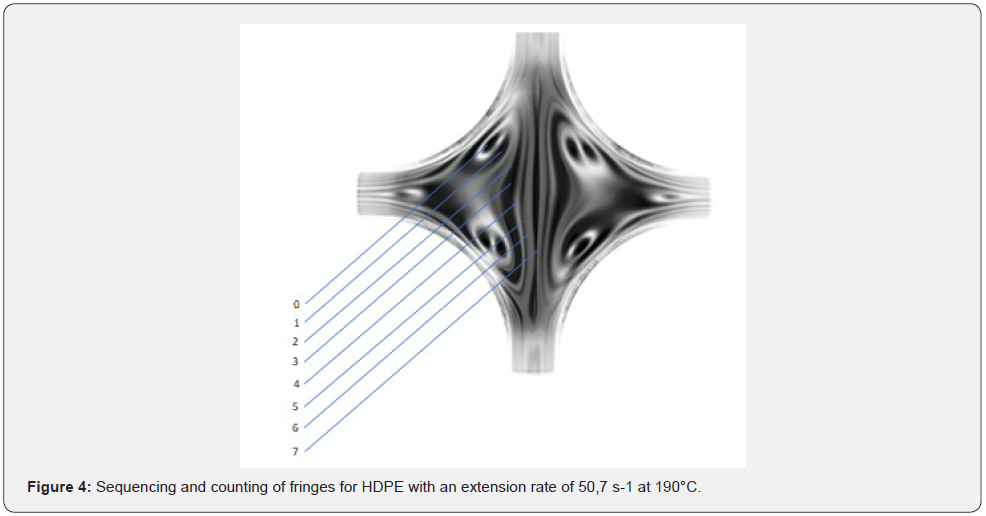

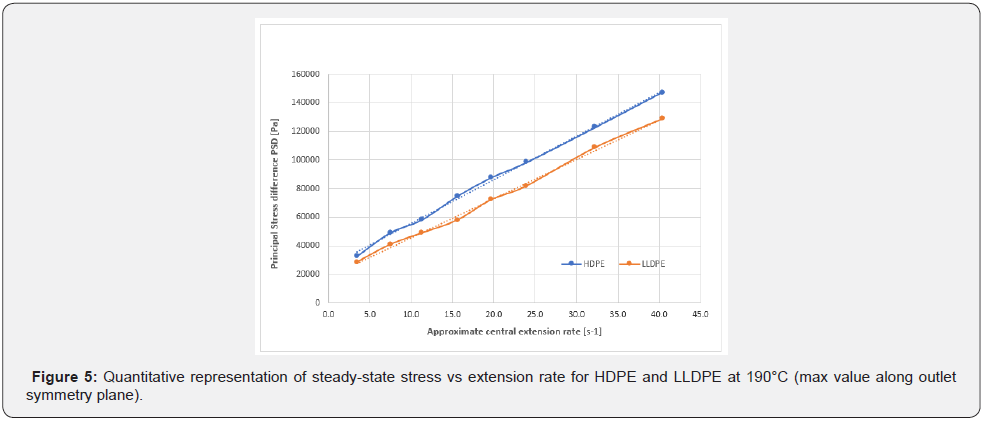

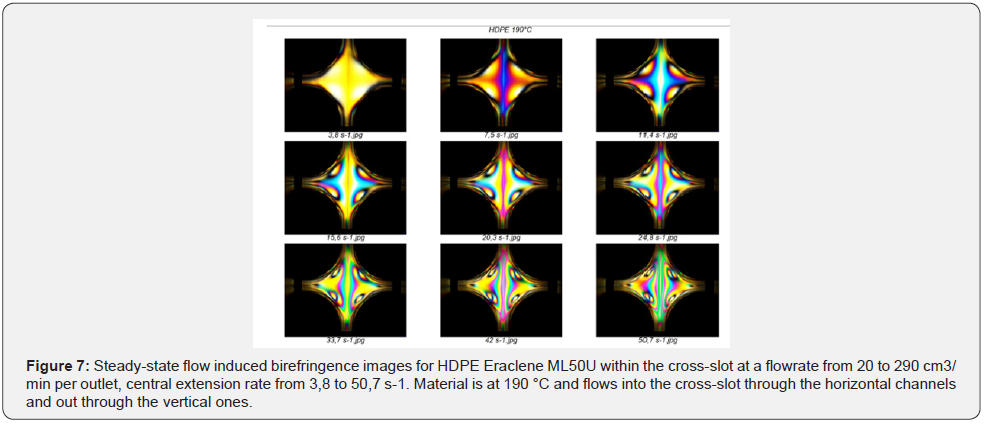

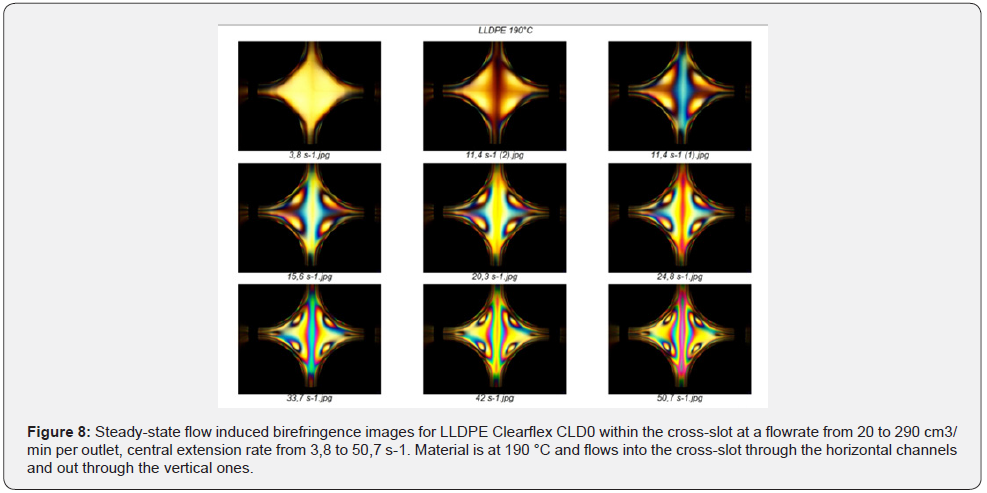

The evolution of the fringes as function of flow rate indicates a progressive increase of level of anisotropy between inlet and outlet channels (Figure 4). The isochromatic fringes of the birefringence are used to determine the principal stress difference in steadystate condition: each fringe carries a fixed stress contribution and through fringe sequencing and assignment of fringe order along the exit symmetry plane (fringe counting technique) is possible to determine PSD. An increase on concentration of isochromatic fringes is observed at high flow rate, mainly located along the exit symmetry plane where stretching flow is supposed to be fully developed. Quantitative representation of stress build-up versus extension rate is well illustrated in Figure 5. The graph corresponds to steady state conditions of fringe patterns. It is observed that the difference in stress between HDPE and LLDPE is maintained throughout the extended range of extension rate investigated. For both materials, the level of stress anisotropy between inlet and outlet channel flow increases as flowrates increase. The difference in stress concentration leads finally to a different evolution of extensional viscosity vs extension rate (Figure 6). The effect of difference in structure between HDPE and LLDPE is also well illustrated in Figure 7 & 8. The differences in fringe numbers sequencing made at same level of extensional rate are representative of the polymer type. LLDPE (short chain branching) shows the lower level on center-line stress fringes on comparison to HDPE (extensive branching), thus indicating for the former a lower stress concentration localized in the area of outlet symmetry plane.

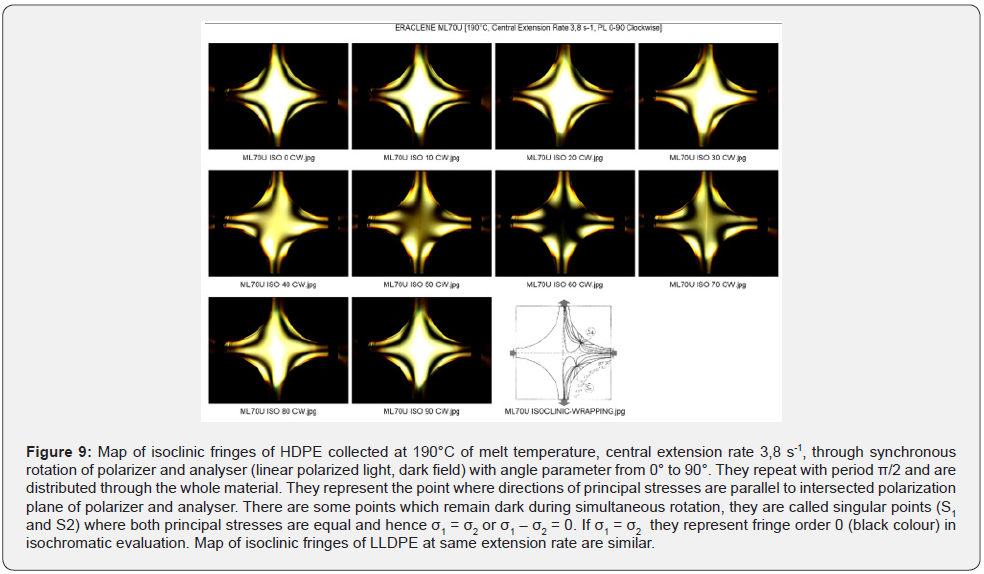

As explained above, the configuration of the optical train used for the evaluations (circular polarization) is such as to examine isochromatic fringes. We have mentioned that with a different optical setup (linear polarization in dark field) is possible to also evaluate the isocline bands, loci of points where principal stresses directions are constant. With this configuration the initial field is dark, the principal stresses on melt produce a pattern of coloured fringes that vary with loading (isochromatic), on the same time some dark bands remain fixed with stress (isoclines); by rotating the polariser and analyser together, the coloured fringes do not vary (isochromatic) while the dark fringes change (clearly detectable isoclines). It has been made an exploratory survey and it has provided an interesting mapping of their distribution (Figure 9). Isoclinic fringes of HDPE are practically superimposable to those of LLDPE, an indicator that materials express a similar spatial orientation of stresses. There are some points which remain dark during simultaneous rotation, they are called singular points (S1 and S2) where both principal stresses are equal and hence σ1 = σ2 or σ1 – σ2 = 0. If σ1 = σ2 they represent fringe order 0 (black colour) in isochromatic evaluation. Isoclinic fringes allow, through a subsequent graphic elaboration, to determine the so-called isostatics which are the trajectories of the stresses. However, this issue is not the subject of this investigation, it will be addressed in future studies.

Summary and Conclusion

The cross-slot device coupled with two extruders allows measurement of steady-state planar extensional viscosity in a broad strain rate regime through stress birefringence. Specifically, the properties of two polyethylenes under extensional flow have been assessed by using this non-invasive rheo-optical approach. This analysis show how steady-state extensional flow can be evaluated through cross-slot measurement and how different branching in the molecular structure has an impact on stress in elongational flow. The PSD at different level of strain rate was captured using flow-induced birefringence. The PSD pattern developed from an initial near-Newtonian response (slow flow, quasi symmetric pattern between inlet and outlet) to gradually increasing level of asymmetry between inlet and outlet flow as the flow rate increases (stretching flow). It has been experimentally verified that these two materials show a difference in extensional viscosity, and the presence of long chain branches in the molecular morphology in HDPE affects the stress in extensional flow. On the other hand, LLDPE shows a lower extensional viscosity. The advantage of this method lies in the possibility to replicate the same temperature of industrial process and extensional optical device has confined geometry that allows the testing on molten polymers that, due their poor melt strength, sagging, localized necking at test temperature, cannot be otherwise tested in free-surface devices (not-confined geometries) like current commercial stretching rheometers.

Additionally, high strain steady-state limit can also be reached in long stable extrusion run. According to our findings, this approach is capable to detect and differentiate extensional rheology of different polymers that would not otherwise be captured with other techniques Cross slot die and rheo-optical analysis does have some limitations. At high stress values, fringes stratification become very high and the sequencing and counting may be more demanding. The PSD patterns for HDPE show a higher level of stress vs LLDPE at same strain rate, and it is observed that sequence of patterns of HDPE is always approximately two levels of fringe orders more forward than the LDPE compared at same level on central extension rate. The difference in growing number of fringes for HDPE versus LLDPE ultimately lead to a different extensional viscosity response. It should be remembered that these two materials have very similar shear viscosity and mater curve, despite significant different degree of branching is present. On the same time the differentiation observed in extensional viscosity is in good qualitative agreement with mechanical behaviour - elastic shear modulus under shear flow - performed via-OSCAR technique. Results obtained with these two techniques corroborate the explanation of the different evidence of extensional behaviour of these two polyethylenes. This also reflected in the industrial field: HDPE is more suitable for extrusion than LLDPE.

The design of the die inevitably leads to a compromise in relation to channel dimension and aspect ratio. Ideally twodimensional flow is desirable, even if an increase in branching enhance localized three-dimensional flow with stress pattern increasingly asymmetric. In conclusion, it has been shown that rheo-optical approach with flow induced birefringence analysis can be used for mapping and measuring properties of melts in extension along the plane of the outlet channels, or simultaneously shear properties in the inlet channels as well, depending on geometry of die, thus providing to be a very useful and intriguing tool to capture the smallest differences in flow behaviour and assess polymer performances. This methodology can become an indicator of rarely observed phenomenon that are not made manifest with conventional approaches and/or non-fully predict with simulation. It can be seen as a complementary approach to current extensional rheometers, towards which it strengthens the measuring range, provides kinematically steady extensional flow, exceeds their limits in maximum allowable testing temperature and applicable extension rate. The connection of the rheooptical die with extruders also guarantees a constant support of homogeneous molten material to the flow cell and above all a long and stable test duration. Lastly, this kind of lay out (cross-slot die and extruder coupling) makes this equipment quite innovative among the available equipment for industrial rheology. It can be used with the purpose of quality control, polymer and compounds design, R&D and optimization in tooling designing.

Future Works

Rheo-optic analysis with cross-slot die coupled with extruders is certainly a field of investigation still to be fully exploited. Further tests with polymers different from each other or belonging to the same monomeric identity but different molecular architecture are to be encouraged, making the most of the potential of the flow-induced birefringence. New potential field of study is certainly the evaluation of isoclines, in parallel to birefringence analysis of isochromatic. Isotropic points appearing in low fringe order zones are often either overlooked or entirely missed in conventional rheo-optical analysis. Vice versa, isoclines and especially their processing into isostatics, could provide complementary information to understand the stress trajectories in flowing materials. This will be the subject of a future work.

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com/

For more articles in Academic Journal of Polymer Science please click on: https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment