The Making Process of Go/CT/PTFE Flat Sliding Plate of High-Speed Railway Bridge Spherical Bearings-Juniper Publishers

Authored

by Shou-ren Wang

Abstract

According to the rapid development of high-speed

railway, the importance of spherical bridge bearings has attracted lots

of attention as an essential connected part between bridge and pillar

[1,2]. As you know, high-speed railway spherical bearings consist of

upper bearings plate, spherical plate, under plate, flat stainless-steel

plate, flat sliding plate, spherical stainless steel plate, spherical

sliding plate, sealing ring, anchor bolt, dustproof shield [3,4]. Flat

sliding plate is an indispensable part of spherical bearings since the

displacement ability of bearings is determined by the sliding behavior

between flat stainless-steel plate and flat sliding plate.

Keywords: Spherical bridge; Steel plate; Sealing ring; Cold pressingMini Review

Now the flat plate is made of PTFE, which is

categorized as a chemical polymer and usually called “the king of

plastic”. As PTFE has a great ability of friction and wear, it has been

used widely. However, PTFE behave badly in creep deformation resistance

unless adding to original PTFE extra material which could improve the

performance to against creep deformation. One of the well-known extra

adding materials is GO [5,6]. GO is a kind of two-dimension nanometer

material with hive-like flat thin film, which is made of sp2 and found

in 2004. Although GO is as thick as one carbon atom, it has high level

yield strength and stiffness, great lubricant performance and excellent

wear-resistance attribute, and it means that GO could reduce friction

coefficient if it mixes with PTFE [7,8]. Another adding material called

CF which also has high level yield strength and elasticity

and could be added to PTFE to improve the wear resistance of material.

But, both GO and CF show low compatibility with PTFE as adding material

and many scholars and experts have

focused on this phenomenon. In this paper, it shows a new kind of making

process of Go/CF/PTFE flat sliding plate of high-speed railway bridge

spherical bearings by KH-550

Weighing Material and Mixing Material

The experimental material is weighed by electronic

universal analytical balance and then placed in grinding room of

planetary ball mill. The parameters are showed below.

Grinding time: 240 minutes, rotate rate: 180r/min, the ratio of ball to sample: 7:1

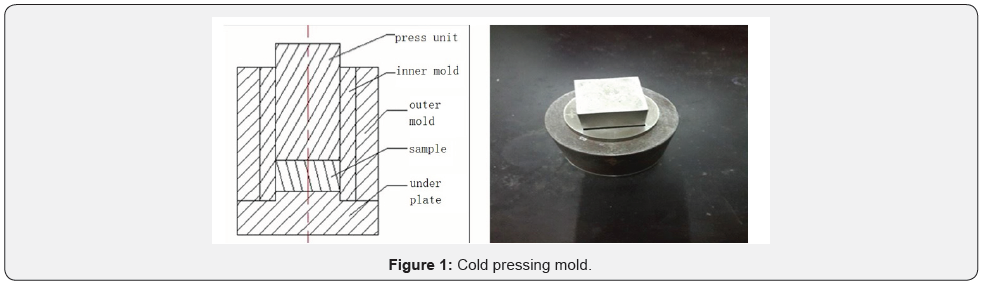

Cold Pressing

Put the sample into mold (Figure 1), and then

Universal hydraulic forming machine could press the sample. With

10MPa/min press velocity, the load pressure should increase gradually to

130MPa and stay for 10 minutes, to make sure the air among the sample

could be expelled entirely.

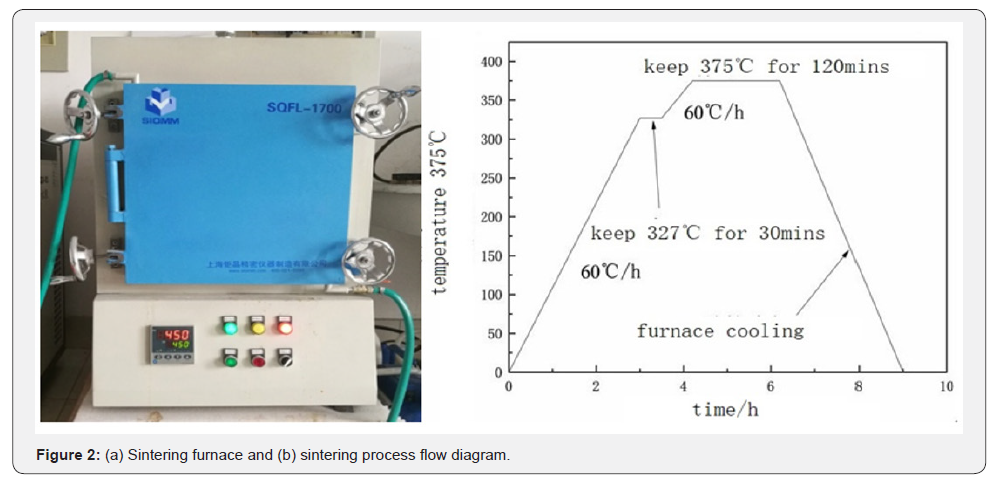

Sintering Solidification

After cold pressing process, the sample should be placed

into electric furnace for sintering. Figure 2 shows process flow

diagram. With 60 oC/h heating velocity, the sample should be

heated up to 327 oC, which is the melting point of the sample,

and then keep the temperature for 30 minutes. And then the

sample should be heated up to 375 oC and keep the temperature

for 2 hours. After furnace cooling process, the sample could be

considered well-prepared [9].

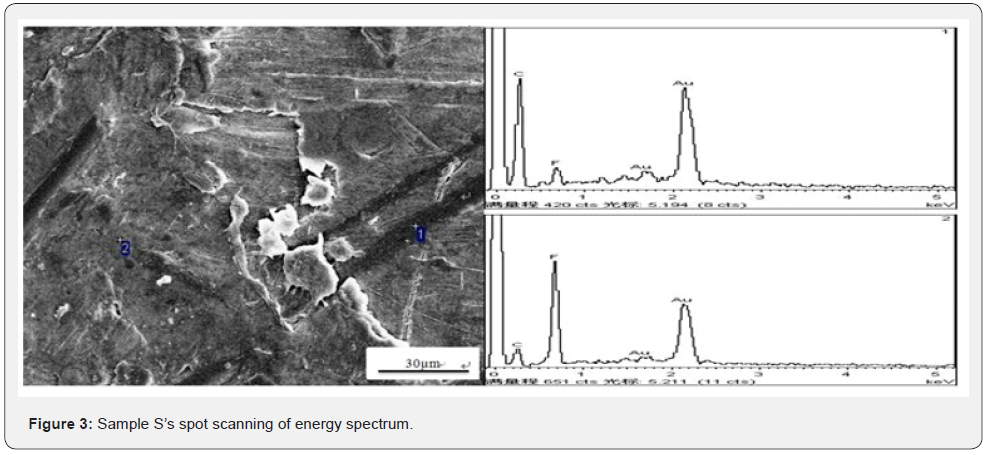

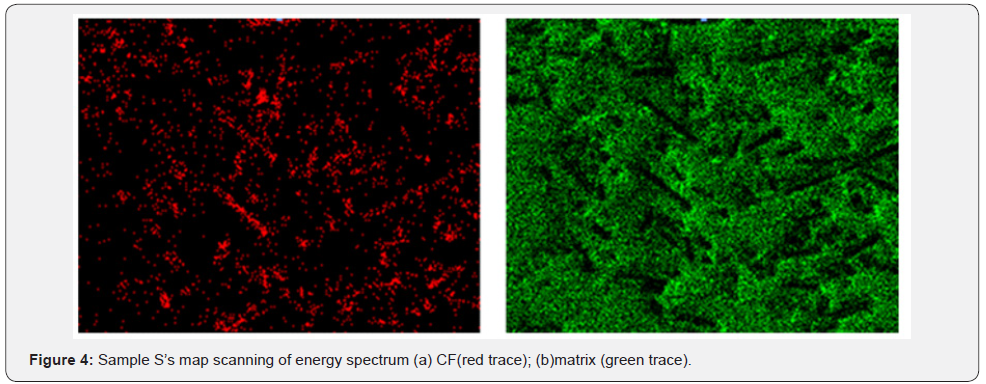

Microstructure Analysis

After making process of flat sliding plate, microstructure

analysis could be completed. Figure 3 shows sample S’s spot

scanning of energy spectrum and Figure 4 shows sample S’s map

scanning of energy spectrum. In Figure 3, area 1 shows trace of

black strip, which is CF, and area 2 shows matrix material. Figure

4 also shows that CF has been distributed evenly in the matrix

material, and it means than CF has relatively good compatibility

and it could improve some kinds of strength property of sliding

plate sample [10]. Figure 5 shows the impact section microstructure

of composite sample. We can conclude that the

interface issue was not good from area 1 in Figure 5.

CF was extracted out from the material when it was

impacted. The combination between CF and matrix would turn

to be loose. Maybe it was caused by the incomplete disposition

by silane coupling agent, or the silane coupling agent disposition

couldn’t improve the interface issue between CF and PTFE.

The tight combination between CF and matrix which is shown

on area 3 in Figure 5, which proved that the interface issue

was solved seemingly. What is shown on area 2 in Figure 5 is

that the mid area of CF has been broken, which proved that CF

could strengthen the matrix. Area 4 in Figure 5 has shown the

gaps in composite material sample. Maybe it was caused by

the fast compressing rate of cold-press molding, or the liquid

evaporation during sintering process which was attributed to

the halfway drying of sample.

Conclusion

Bearings’ sliding plate sample could be made by cooling

press process and sintering solidification successfully, and since

CF could be distributed evenly among matrix, it illustrates that

CF could reduce wear and friction for material.

For more

details Journal of Polymer Science please

click on: https://juniperpublishers.com/ajop/index.php

To read more…Full Text in Juniper Publishers click on https://juniperpublishers.com/ajop/AJOP.MS.ID.555566.php

Comments

Post a Comment