Production of NSSC Cellulosic Pulp Fibers from Eucalyptus Cameldulensis- Juniper Publishers

JUNIPER PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

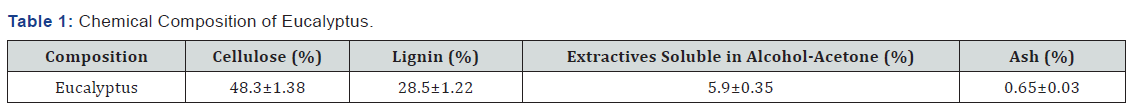

This study has aimed to investigate production of

neutral sulfite semi-chemical (NSSC) pulping from eucalyptus

camaldulensis in Zabol, Sistan & Balouchestan, Iran. Chemical

composition including cellulose, lignin, extractive and ash were

measured (48.33%), (28.49%), (5.94%) & (0.65%) respectively, while

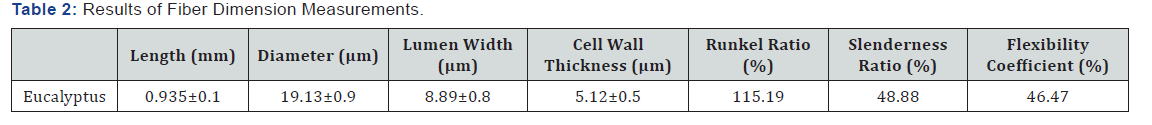

dimension of fibers including length (0.935mm), diameter (19.13μm),

lumen cavity (8.89μm) & cell wall thickness (5.12μm). Cooking

conditions were consist of three levels of chemical charge (10, 14 &

18% on O.D weight), constant time of 90min, constant temperature of 170

°C & liquor to wood ratio of 7:1. The pulps were refined to

400±25mL, CSF & 127gm-2 hand sheets were made. Finally, strength

properties of the pulps were compared and evaluated with that of

Mazandaran Wood and Paper Industries (MWPI), Iran. The results showed

that pulp yield decreases with increase of chemical charge. Analysis of

the mechanical properties indicated that the paper from NSSC of

eucalyptus at various cooking levels has preference of NSSC pulp of

hardwoods produced in MWPI for all strength indices.

Keywords: Eucalyptus camaldulensis; Chemical charge; Pulp; NSSC

Introduction

The use of fast-growing species, such as tagasaste,

leucaena, paulownia [1-3]. The fast-growing commercial plantations of

Eucalyptus species have nowadays an important role in the fulfillment of

the worldwide increasing demand for pulpwood [4]. By 2008, the total

area of Eucalyptus plantations, mainly distributed in about one dozen

countries spread worldwide, [5] exceeded 19 x 106ha [1]. In fact, the

Eucalyptus species are the most important fiber sources for pulp and

paper production in South-West Europe (Portugal and Spain), South

America (Brazil and Chile), South Africa, Japan, Iran and other

countries [6].

Nowadays researchers are engaged in applying those

pulping processes which needs less chemical for the production process

due to environmental concerns. In this regard, NSSC process, as one of

the production processes which observes environmental issues, requires

further investigations to optimize the production method along with

economic and ecological objectives for reducing the chemical charge and

application of the proper species [7]. Neutral Sulfite Semi-Chemical

process briefly called NSSC is mainly used to produce high-yield pulps

from

hardwoods. Sodium sulfite cooking liquor is used in this process to

neutralize organic acids released from lignocelluloses materials during

cooking with small amounts of sodium carbonate, sodium hydroxide or

sodium bicarbonate [8]. These materials are utilized for initial

treatment while separation of the fibers is finally accomplished by

mechanical processes. On the other hand, limitations in utilization of

wood from forests in northern part of Iran, entails looking for

alternative sources from various parts of the country. Eucalyptus,

especially camaldulensis are of quick growing species which is expected

to be consistent with ecological conditions of Iran. Eucalyptus has

special value and importance considering the continental conditions of

Iran with large arid areas [9]. Based on global research and experiences

in making pulping from eucalyptus wood species [9-14] the purpose of

this research was to investigate chemical composition and biometrical

properties of the fibers from eucalyptus camaldulensis, production of

NSSC pulp from it and finally, comparison of the mechanical properties

of the handsheet papers with those samples made in MWPI.

Experimental

Materials

Three eucalyptus camaldulensis trees from agriculture

researches station of Zabol were selected randomly and cut

down. Logs of Breast height were cut and prepared from each

tree. This region has hot and dry climate such that its yearly

maximum temperature reaches 45 °C. Meanwhile, annual

precipitation of this region is 41mm and so-called 120-days

wind of Sistan is of the dominant phenomena in this region.

Measurement of chemical composition

Measuring percentage of cellulose was done through

nitric acid method [15], while percentage of lignin, extractives

soluble in acetone, and ash content were measured according to

TAPPI test methods T222-om-98, T204-om-97 & T211-om-93,

respectively.

Measurement of fibers dimensions

Franklin’s technique (1954) was used to prepare the

samples. Dimensions of the fibers including length and diameter,

Lumen width and thickness of cell wall were measured by

LeicaQ5000MC Image analyzer apparatus and biometric ratios

and coefficient being calculated from the following equations:

Slenderness Ratio = L/d ………(1) [16]

Flexibility coefficient = (c/d)*100....(2) [17]

Runkel Ratio(tear strength of fiber)=(2p/c)*100....(3)[18]

Experimental Pulping

Three amounts of chemicals of sodium sulfite (Na2SO3) and

sodium bicarbonate (Na2CO3) (10%, 14%, & 18%, on the basis of

oven dry mass of eucalyptus) and constant pulping time of 90min

were used. For each combination of variables, 3 replica pulp

samples were made. A pulping temperature of 170 °C was kept

constant. The cooking liquor to eucalyptus (L/W) was at a 7-1

ratio. The cooking trials were performed using an experimental

rotating digester (HATTO), with 500 grams of eucalyptus in each

trial. Pulping time was measured after reaching 170°C. The time

to reach the cooking temperature was adjusted at 30 minutes. At

the end of each cooking, the content of the cooking cylinder was

discharged on a 200-mesh screen, and the cooked material was

washed using hot water. The remaining liquor was separated by

hand-pressing the cooked material. Digester yield was measured

by weighing the washed material on top of the screen without

defibration. The cooked material was defibrated using a 25cm

laboratory single-disc refiner, and then pulp was screened using

a set of 2 screens, a 12-mesh screen on top of a 200-mesh screen.

The material remaining on the 12-mesh screen was considered

as reject (shives), and the fibers that passed the 12-mesh screen

but remained on the 200-mesh screen were considered as

accept. To estimate the required refining, initial freeness was

determined according to TAPPI 227 om-92, and then the pulp

was refined to 400±25 mL CSF according to TAPPI 248 om-88,

with a PFI Mill. Hand sheets (with basis weight of 127gm-2)

were made according to TAPPI 205 om-88. Hand sheets were

kept in a conditioning chamber at 23 °C & 50% RH for 24 hours.

Then, basic weight, caliper, Corrugating Medium Test (CMT),

Ring Crush Test (RCT), stiffness and tensile strength index,

tear strength index, and the burst strength index of the hand

sheets were determined according to TAPPI T410 om-98, T411

om-89, T809-om-99, T818-om-87, T240 om-92, SCAN P11:73,

T403 om-91, and T403 om-91 test methods, respectively. Oneway

Variance Analysis test was used to analyze differences in

strength properties of the hand sheets due to change in chemical

charge of cooking liquor at confidence level of 95%. Meanwhile,

average values of the properties were classified using Duncan

multiple range testing.

Results and Discussion

Chemical composition and fiber dimensions

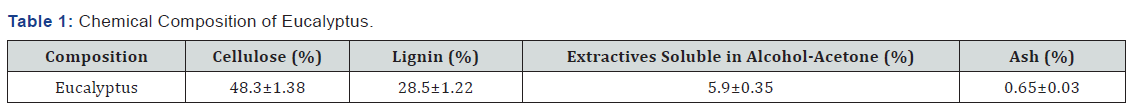

The percentage of cellulose, lignin, extractives soluble in

alcohol-acetone, and ash are summarized in Table 1. Fiber

dimensions and biometrical coefficient of eucalyptus are

summarized in Table 2. The cellulose content of eucalyptus was

found to be 48.3%, which is in the satisfactory range for pulp

production. The cellulose content of eucalyptus is more than rice

straw (41.20%) [19]and wheat straw (38.20%) [20]. The lignin

content of eucalyptus was found to be higher than rice straw

(21.90) and Egyptian cotton stalks (22.50) [21]. The Extractives

soluble in alcohol-acetone content of eucalyptus was found to be

almost similar to rice straw but higher than aspen (2.50%), and

lower than wheat straw (7.80%). The ash content of eucalyptus

was also low.

Chemical composition of the raw material is one of the most

important factors in pulp and paper production. Therefore,

identification of chemical composition of eucalyptus has

significant importance for predicting properties of the paper

made. Cellulose is the most important component of cell wall

in pulping process. Strength properties of paper increase with

greater percentage of cellulose. Lignin is another component of

cell wall which is responsible for connection of fibers to each

other. Removing lignin is known as one major objective for any

pulping process since once lignin has been solved and removed,

cellulose fibers can establish more intermolecular bonds which

will lead to higher strength of the paper produced [22].

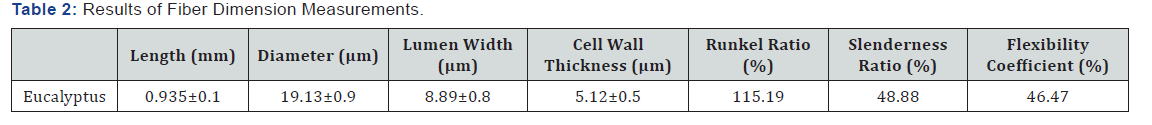

Fibers were classified into three groups. The first group was

considered short fibers with lengths of less than 0.9mm such as

hardwood. The second group had an average length between

0.9-1.9mm. The results showed that the average fiber length of

eucalyptus was 0.935mm. The third group included fibers longer

than 1.9mm [23]. Eucalyptus fibers are shorter than wheat straw

(1.73mm) [24]. On the other hand, the cell walls of eucalyptus

fibers are thicker than those of aspen (1.93μm) (Law and Jiang

2001) [25] and cotton stalks (3.40μm) [26]. The calculated

Runkel ratio for eucalyptus fibers (115.19%) is higher than

that of cotton stalks (84%), aspen (23%), and date palm rachis

fibers (80%). The slenderness ratio of eucalyptus fibers is 48.88

and is higher than that of cotton stalks (42.35) and aspen fibers

(46.15), but the flexibility coefficient of eucalyptus fibers is less

than both cotton stalks (65.31) and aspen (81.44). This indicates

good sheet forming potential from these fibers.

Dimensions including Length, diameter, lumen width and

cell wall thickness have great effects on physical and mechanical

properties of papers. In this regard, length of fibers has a very

distinct role on improving strength indices of paper. Generally

speaking, an acceptable amount for slenderness ratio for pulping

is believed to be higher than 33 [27] such that eucalyptus fibers

will be stand at this range.

Pulping and pulp evaluation

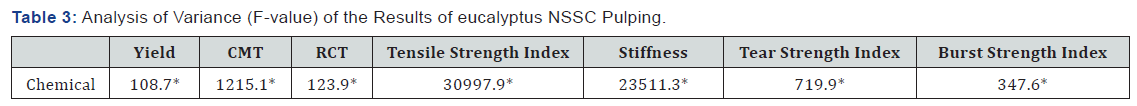

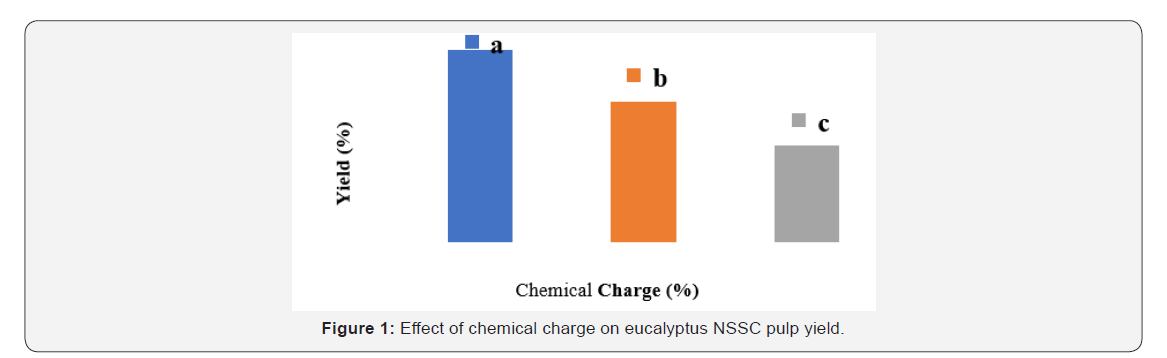

Pulp yield after cooking is one important characteristic which

must be measured after pulping process. The results show that a

higher chemical charge reduced digester yield. The yield of these

pulps varied between the highest values of 74.18% to the lowest

value of 67.1%. Statistical analysis indicated that the effect of

chemical charge as well as the combined effect of the variables

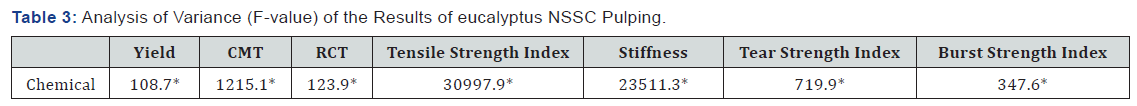

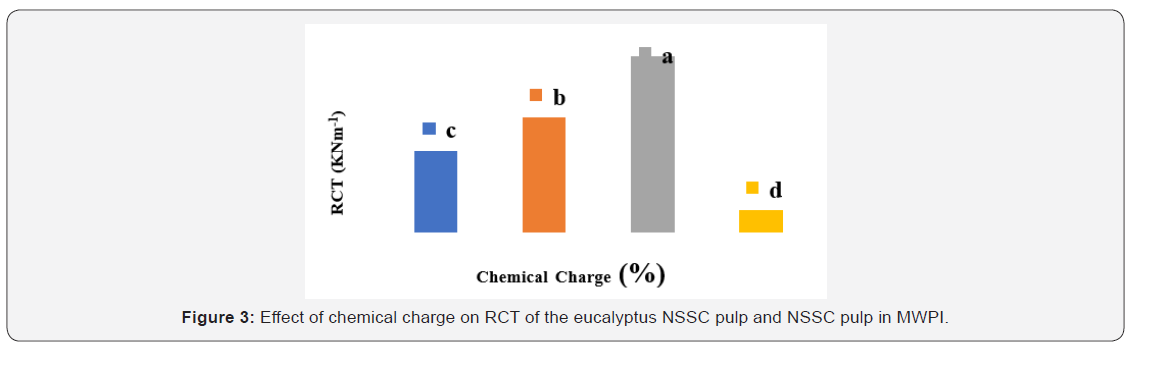

on digester yield was statistically significant at 95% (Table 3).

Therefore, to compare the averages, the Duncan multiple range

test was used, and the results are shown in each figure using

lower case letters. An increase of chemical charge resulted in a

decrease of the pulping yield because of lignin and carbohydrate

dissolution, especially hemicelluloses (under the influence of

sodium sulphite and sodium bicarbonate). Generally, charging

10% chemical led to the greatest yield, and the lowest yield was

related to 18% chemical charge as expected [23].

Intensity of chemical reactions and delignification is increased

with greater amount of chemicals used and the raw material

becomes much softer. Thus, fibers will be separated more

simply and there would be a better refining. Deniz I et al. [20]

have reported that the effect of utilized chemical charge on properties

of pulp is very crucial as the pulp yield is reduced with

higher amounts of chemicals in the cooking liquor.

Furthermore, results of freeness distinguished that by increasing

the percentage of chemical charge, treatment will be intensified,

lignin dissolution will be increased, and water passing

through pulps will be decreased due to more bonds between fibers.

Moreover, greater amounts of chemical will intensify chemical

reaction; encourage penetration of chemical into fiber structures;

and increase their swelling which will lead to improve

refining of the fibers. As a result, needed rotations of the refiner

for meeting the desired freeness will be decreased.

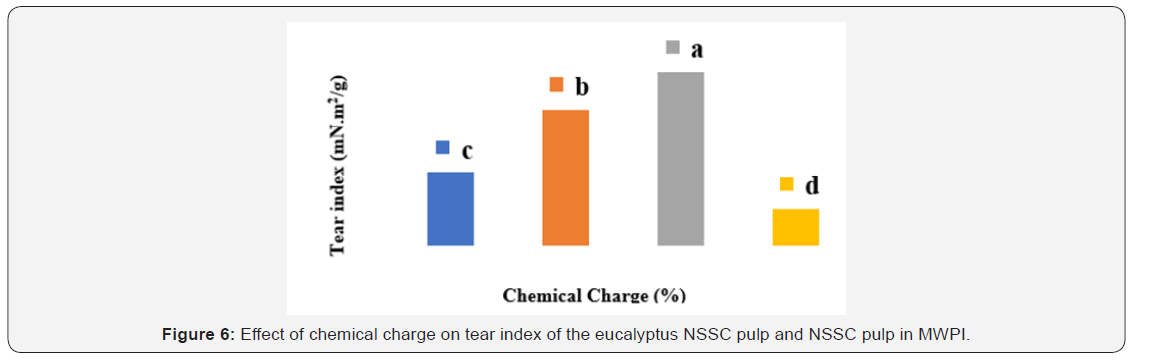

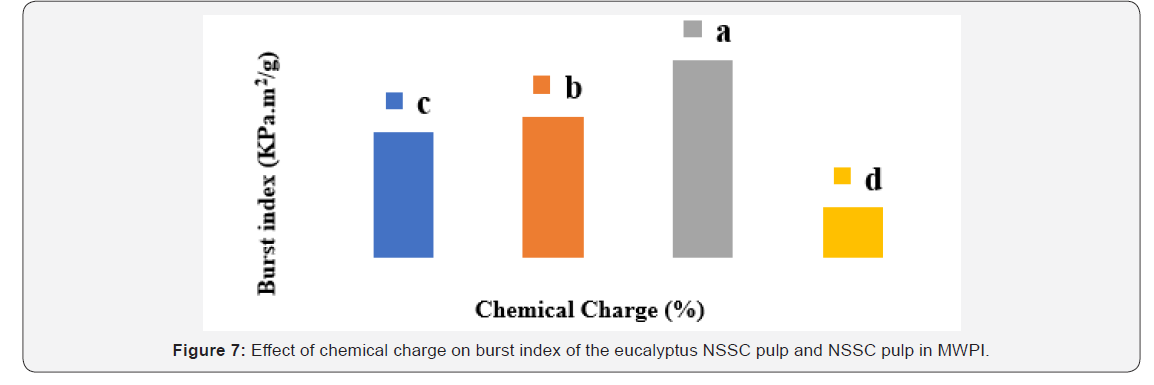

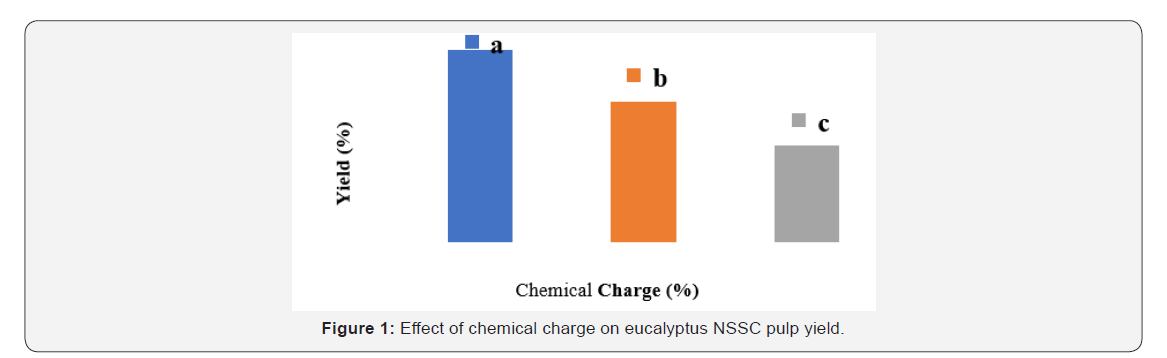

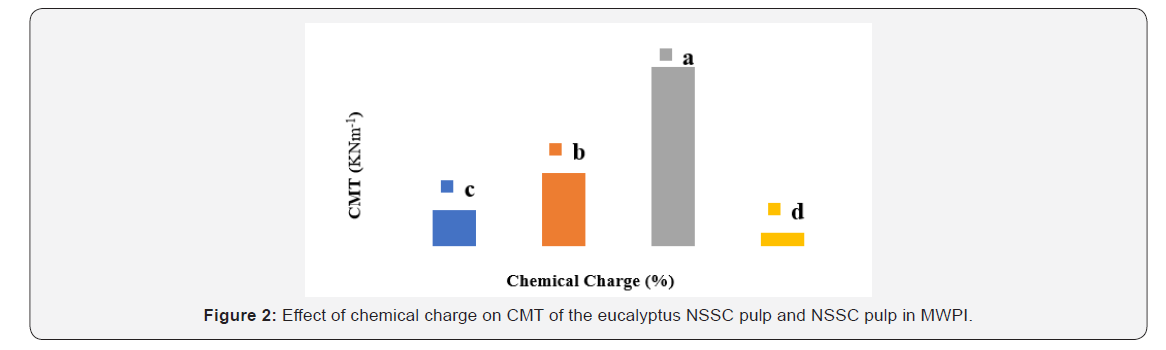

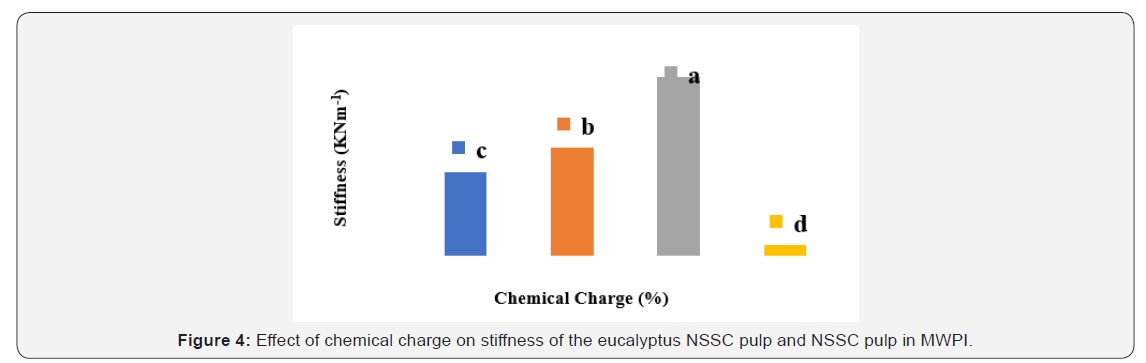

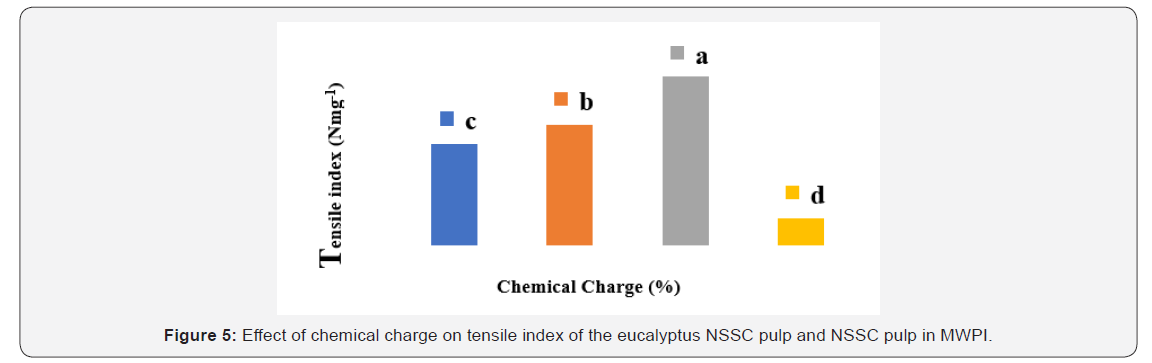

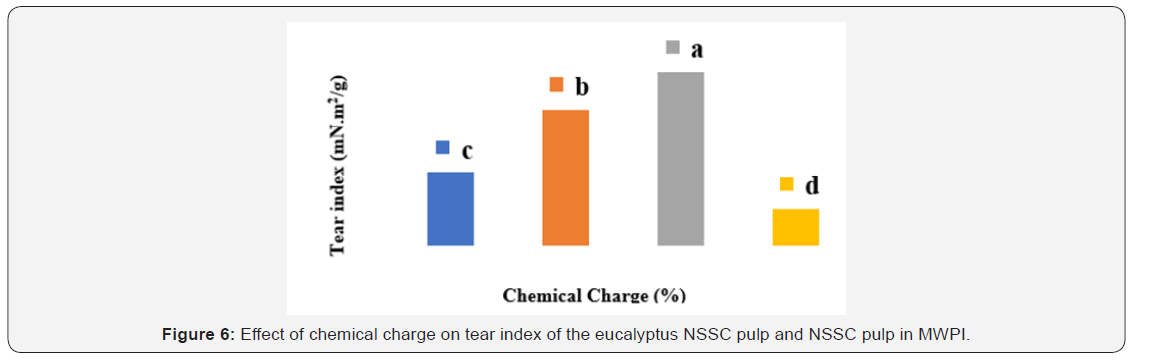

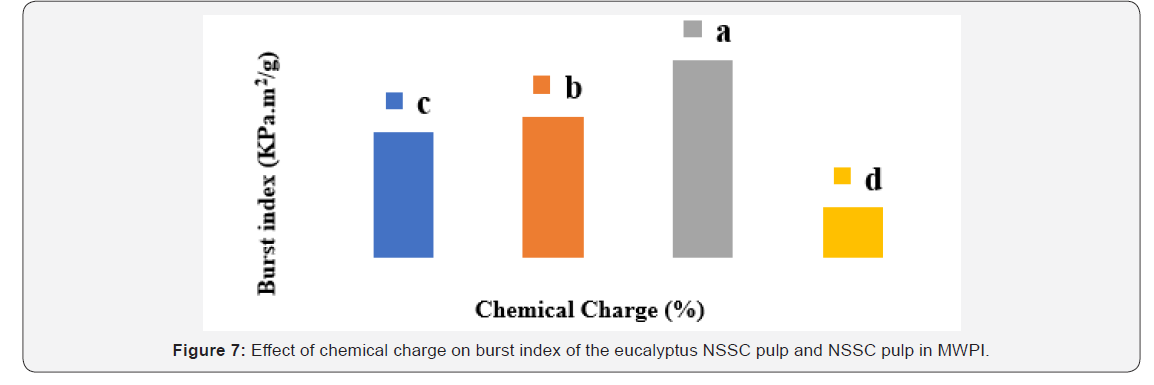

The impact of chemical charge on strength properties, including

tensile strength index, burst strength index, and tear

strength index, was statistically significant at 95% (Table 3). The

results showed that a higher chemical charge increased pulp

strength property.

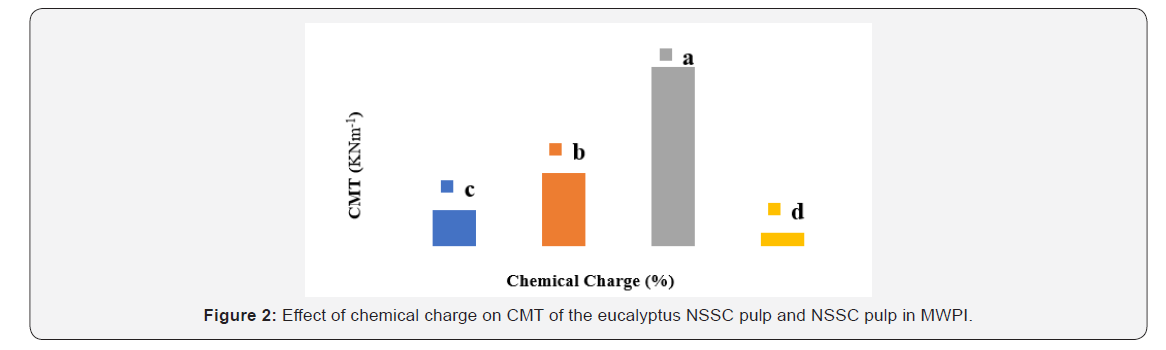

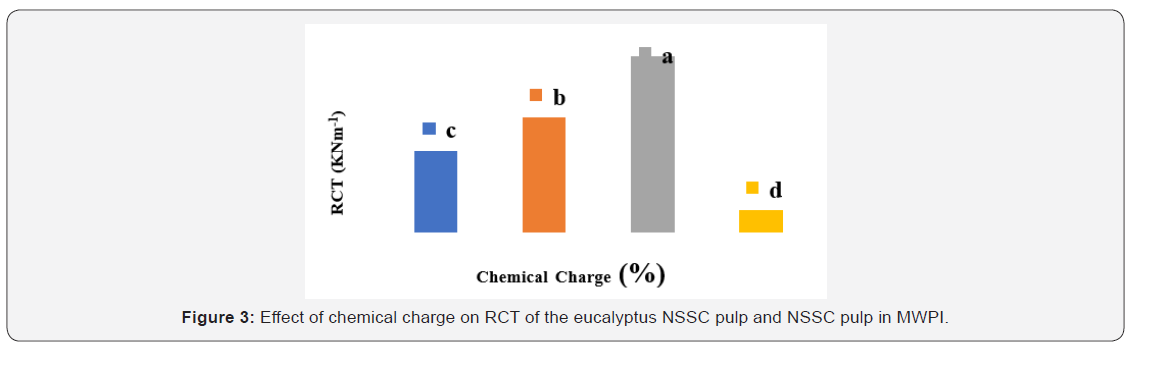

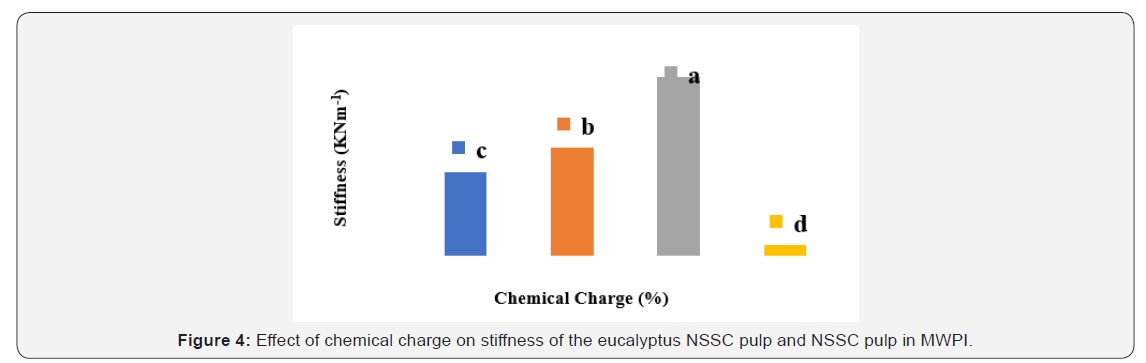

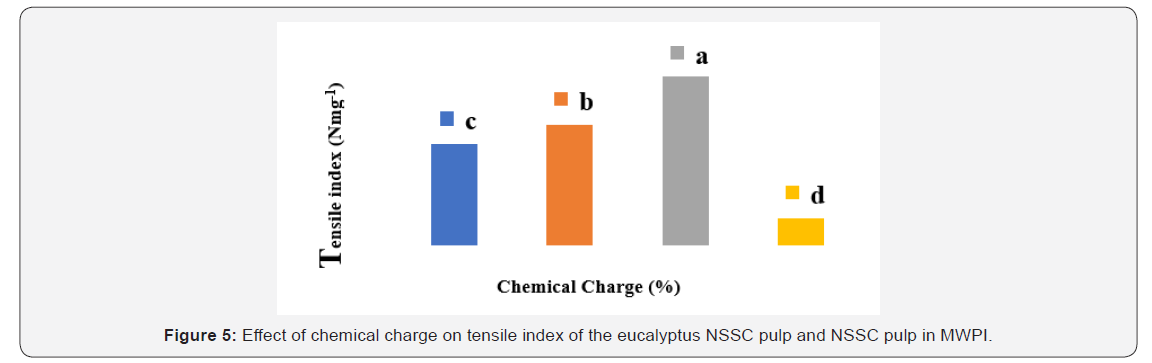

Even though the influence of chemical charge on strength

indices revealed that higher chemical charges improved the

strength values of the pulps, CMT, RCT, tensile index, Stiffness,

tear index, and burst index, increased to 217.33KNm-1, 1.95KNm-

1, 54.79Nmg-1, 770.22KNm-1, 7.43mNm2g-1 & 3.86kPam2g-1,

respectively. While the lowest value is related to the paper

produced from pulp of MWPI, due to elimination of more lignin.

The most effective factors on mechanical properties are

quality and quantity of bonds among fibers, fibers strength

and length of fibers [28]. Among these factors, “bonds between

fibers” is more important than others. Refining of the pulps

introduces a positive effect on strength properties of the papers

produced. Comparison of the sample (NSSC pulp of MWPI)

(Figure 1) with the papers made from eucalyptus wood shows

that the later were refined with higher rotations. Further

refinement increases the quality and quantity of bonds between

fibers, improves flexibility and thus, more fiber fibrillation

than before. So enhanced mechanical properties of the papers

made from eucalyptus can be partially attributed to the further

refinement of its resultant pulps.

Higher tear index of the eucalyptus paper can be explained

by better biometrics coefficients which cause better refinement

of the fibers and leads to improved bond of papers prepared

from eucalyptus, as the most effective factor on the tear strength

index is length of fibers. Increased length of the fibers improves

tear strength, since in this case greater force would be required

to cut the fibers [29]. In fact, length of fibers, slenderness ratio

and Runkel ratio of eucalyptus fibers are almost the same as

hardwoods of forests in northern Iran and even its Runkel ratio

(115.19μm) is far better than many industrial hardwood species

which itself can improve tear index additionally.

Two factors are effective on burst strength properties,

namely length of fibers and bonds between fibers. Although

increased length of fibers may lead to higher burst index, this

characteristic is more dependent on the bonding between fibers.

Increased rotations of refiner will also enhance burst strength to

some extent, while additional removing of lignin from pulp and

formation of stronger bonds within pulp will also improve burst

strength characteristics. The above-mentioned reasons can

explain higher burst strength index for the samples produced

from eucalyptus at various cooking conditions.

Figures 2-7 show the effects on pulp strength properties

under the influence of chemical. The maximum amount of

strength indices observed in the NSSC pulp produced by 18

% chemical charge while the minimum amount of them was

observed in the NSSC pulp made in MWPI. It can be observed

that all average values of resultant papers are categorized in four

distinct groups (Figures 2-7).

Conclusion

a) The result of chemical content of eucalyptus is in the

satisfactory range for pulp production.

b) The results showed that pulp yield decreases with

increase of chemical charge.

c) Analysis of the mechanical properties indicated that

the paper from NSSC eucalyptus at various cooking levels

has preference to NSSC pulp of hardwoods produced in

MWPI for all strength indices.

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com

For more articles in Academic Journal of Polymer Science please click on:https://juniperpublishers.com/ajop/index.php

For more Open Access Journals please click on: https://juniperpublishers.com

Comments

Post a Comment