Major Reduction in Chemical Curatives for Rubber Articles-Juniper Publishers

JUNIPER PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Opinion

The sulfur cure system in the

ethylene-propylene-diene (EPDM)-based Curtain Wall Seal (CWS) has two

accelerators, adding up to 2.75 parts per hundred rubber (phr) by

weight, and two activators (ZnO: 5phr, stearic acid:1phr) [1]. In total,

8.75phr chemicals are used to fully cure the article with 1phr

elemental sulfur. In rubber formulations, chemical curatives are

indispensable and once reacted with sulfur at elevated temperature, they

produce crosslinks between the rubber chains and provide shape

stability, which is essential for the performance, durability and life

of the final product in service. Excessive use of chemical curatives is

harmful to health, safety, and the environment. According to the

European Directive 67/548/EEC, chemicals such as sulfenamide

accelerators, zinc oxide and stearic acid are very toxic to aquatic

organisms [2]. Stearic acid causes skin and eye irritation in human and

is classified as highly flammable [3]. These chemicals are used

extensively in the sulfur vulcanization of a wide range of EPDM-based

rubber articles.

Keywords:

Ethylene-Propylene-Diene rubber; N-tert-butyl-2-benzothiazole

sulfenamide; Zinc oxide; Stearic Acid; Vulcanization; Oscillating Disc

Rheometer

Aims & Objectives

The aim of this study was to significantly reduce use

of N-tert-butyl-2-benzothiazole sulfenamide (a fast curing delayed

action accelerator, Santocure TBBS) and zinc oxide (primary activator)

in the sulfur cure systems of EPDM-based Curtain Wall Seal and eliminate

stearic acid (secondary activator) entirely from the cure system. A new

method for measuring the exact optimum amount of the chemical curatives

required in the sulfur vulcanization of EPDM rubber was used [4]. All

the cure tests were performed at 160oC in an oscillating disc rheometer

(ODR) curemeter to produce cure traces from which scorch and optimum

cure times, cure rate index and minimum and maximum torques were

measured.

Experimental

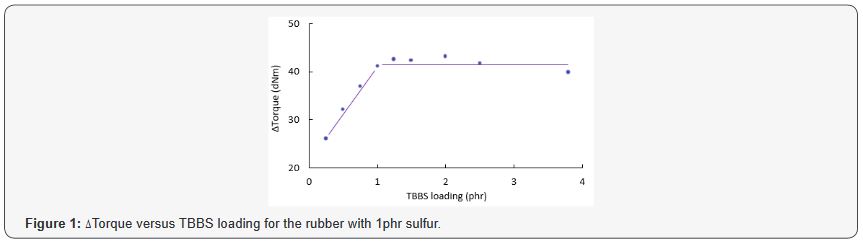

Figure 1 demonstrates Δtorque versus TBBS loading for

the EPDM rubber with 1phr sulfur. ΔTorque, which is the difference

between the maximum and minimum torques on the cure trace of the rubber

and is an indirect indication of crosslink density changes in the

rubber, increased steeply from 26 to 42 dNm as the loading of TBBS was

boosted from 0.25 to 1phr. Subsequently, there was no improvement in

Δtorque once the amount of TBBS reached 3.8phr. Apparently, 1phr TBBS

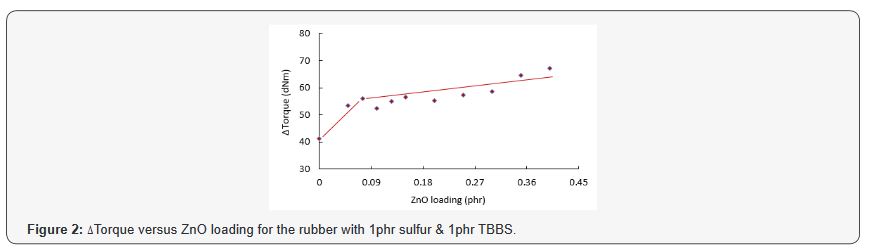

was enough to react the sulfur with the rubber. Zinc oxide was then

added to improve the efficiency of TBBS. ΔTorque rose noticeably from 41

dNm at 0 phr ZnO to 56 dNm at 0.075phr ZnO and the rate of increase

slowed down significantly thereafter. Δtorque then reached to about 67

dNm when the loading of ZnO was raised by an additional 0.325phr (Figure

2). It is interesting that a small amount of ZnO, i.e. as low as

0.075phr, had such a major influence on the performance

of TBBS in the cure system as indicated by a significant rise

in Δtorque. When 0.5phr stearic acid was mixed with the EPDM

rubber with 1phr sulfur, 1phr TBBS & 0.075phr ZnO, torque decreased

from 56 to 47 dNm. torque subsequently continued decreasing

slowly to about 42 dNm when the loading of stearic acid

was raised to 2.5phr (Figure 3). Evidently, the crosslink density as

indicated by Δtorque did not benefit from the addition of stearic

acid to the rubber. Moreover, the scorch and optimum cure times

increased, and the rate of cure as indicated by the cure rate index

declined noticeably when stearic added was added [4]. Consequently,

stearic acid was eliminated from the cure system entirely.

In the absence of stearic acid, no zinc stearate was formed in the

rubber. Hence, zinc stearate is not an essential ingredient in the

curing of rubber as has been claimed [5]. The scorch time (ts2) and

the optimum cure time (t95) were 6.2 & 21.5 min, respectively. The

rate of cure as indicated by the cure rate index (CRI) was 6.5 min-1.

Clearly, requirement for the accelerator and primary and secondary

activators to fully cure the rubber at 1phr loading of sulfur is

much lower, i.e. TBBS by 64wt%, zinc oxide by 98.5wt% and stearic

acid by 100wt%, than the amounts currently used in the cure

system of the CWS at the same loading of sulfur. All the indications

are that a significant decrease in the loading of the chemical curatives

in the cure system has no adverse effect on the vulcanization

of the article. In fact, cure efficiency improves when less

accelerators and activators are used with sulfur. This method can

be applied to reduce excessive amount of the chemical curatives

in other industrial rubber articles.

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com

For more articles in Academic Journal of Polymer Science please click on:https://juniperpublishers.com/ajop/index.php

For more Open Access Journals please click on: https://juniperpublishers.com

Comments

Post a Comment