Deep Eutectic Solvents in The Synthesis of Polymers-Juniper Publishers

JUNIPER PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

Deep Eutectic Solvents (DESs), a subclass of ionic

liquids, have emerged as sustainable and green solvents in chemical

reactions. In this mini-review article, deep eutectic solvents

utilization in the polymer synthesis will be discussed briefly.

Keywords: Deep eutectic solvents; Polymer synthesis; Green chemistry

Abbrevations:

DES: Deep Eutectic Solvents; HBA: Hydrogen Bond Acceptor; HBD: Hydrogen

Bond Donor; PDCs: Poly Diol-Co-Citrates; PAAc: Poly (Acrylic Acid);

PMAAc: Poly Methacrylic Acid; APS: Ammonium Persulfate; EM: Eutectic

Mixture; FP: Frontal polymerization

Introduction

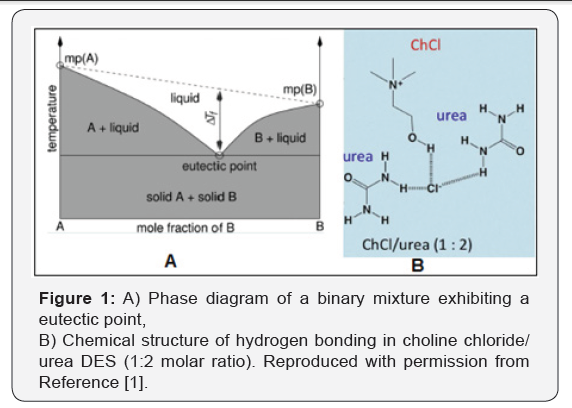

Solvent utilization creates the largest volume of

auxiliary waste in polymer synthesis. However, increasing awareness of

the environmental problems has led to the use of alternative reaction

media to reduce or eliminate organic solvent use. Deep eutectic solvents

(DESs) are systems formed from a eutectic mixture of Lewis or Bronsted

acids and bases which can contain a variety of anionic and/or cationic

species [1]. They incorporate a hydrogen bond acceptor (HBA) and a

hydrogen bond donor (HBD), which are able to give a eutectic with a

melting point much lower than either of the individual components

(Figure 1) [2]. One of the most significant deep eutectic phenomenon’s

was observed for a mixture of choline chloride and urea in a 1:2 mole

ratio respectively. The resulting mixture has a melting point of 12°C,

which makes it liquid at room temperature. DESs are obtained by

complexion of quaternary ammonium salts with hydrogen bond donors. The

charge delocalization occurring through hydrogen bonding between the

halide anion and the hydrogen donor

moiety is responsible for the decrease in the freezing point of the

mixture relative to the melting points of the individual components

(Figure 2) [3].

DESs share many characteristics of conventional ILs

(e.g. non-volatile, nonreactive with water, and biodegradable) while it

offers certain advantages. The preparation of eutectic mixtures in a

pure state can be accomplished more easily than that of ILs with no need

of post-synthesis purification due to the purity of the resulting DES

will simply depend on the purity of its individual components. Moreover,

the low cost of those eutectic mixtures based on readily available

components (for instance, urea and choline chloride are a well-known

example) makes DESs share many characteristics of conventional ILs (e.g.

non-volatile, nonreactive with water, and biodegradable) while it

offers certain advantages. The preparation of eutectic mixtures in a

pure state can be accomplished more easily than that of ILs with no need

of post-synthesis purification due to the purity of the resulting DES

will simply depend on the purity of its individual components. Moreover,

the low cost of those eutectic mixtures based on readily available

components (for instance, urea and choline chloride are a well-known

example) makes

Green Polycondensations

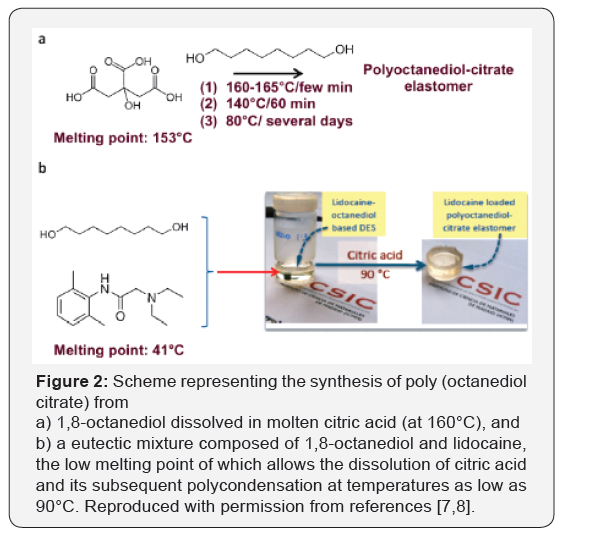

The polycondensation of citric acid with 1,8-octanediol for the

synthesis of Poly (Diol-Co-Citrates) (PDCs), were first reported

by Yang et al. [5,6] in 2004 and, similar to other biocompatible

polyesters, have indicated tremendous versatility as polymeric

networks for regenerative medicine. The conventional synthetic

process first consists of citric acid melting by thermal treatment

at 160-165°C for a few minutes (Figure 1). Then, 1,8-octanediol

is dissolved in this molten phase and polycondensation starts.

The temperature is maintained at 140°C over 60 min, and then

reduced to 80°C to let the reaction to proceed over several days

until completion. Deep eutectic solvent-assisted syntheses offer

an interesting opportunity to fits well with green chemistry.

For example, the mixture of 1,8-octanediol and lidocaine, which

is a local anesthetic, in stoichiometric molar ratios forms a

eutectic with a melting point of about 40°C. Citric acid can

easily be dissolved in this eutectic mixture and polycondense

with 1,8-octanediol at temperatures far below those described

above for regular polycondensations (Figure 2). Lidocaine was

finally entrapped with a high loading due to the stoichiometric

in which it formed part of the eutectic mixture into the resulting

polyesters. Thus, we were able to obtain drug-eluting materials,

the controlled release of which into an aqueous medium was

simply based on the biodegradable character of the polyester

network. It is worth noting that lidocaine would decompose (at

least, partially at 155°C) following regular polycondensation

[7,8].

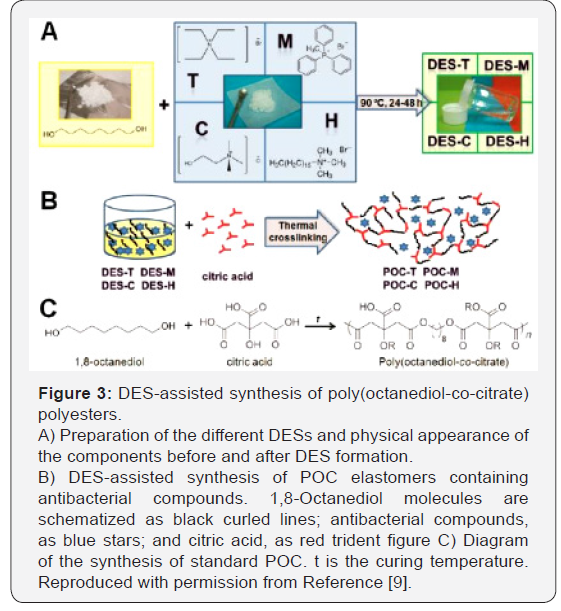

Also, Serrano et al. [9] in another research, prepared

biodegradable poly(octanediol-co-citrate) polyesters with

acquired antibacterial properties by the DES-assisted

incorporation of quaternary ammonium and phosphonium salts

into the polymer network (Figure 3) [9]. Remarkably, the resulting

polymers preserve their cytocompatibility while showing elastic

properties advantageous for their use as wound dressings. In the

resulting polymers, the presence of salts such as: choline chloride,

tetraethylammonium bromide, hexadecyltrimethylammonium

bromide, and methyltriphenylphosphonium bromide, inhibits

bacterial growth in the early post implantation steps, as tested

in cultures of Escherichia coli on solid agar plates.

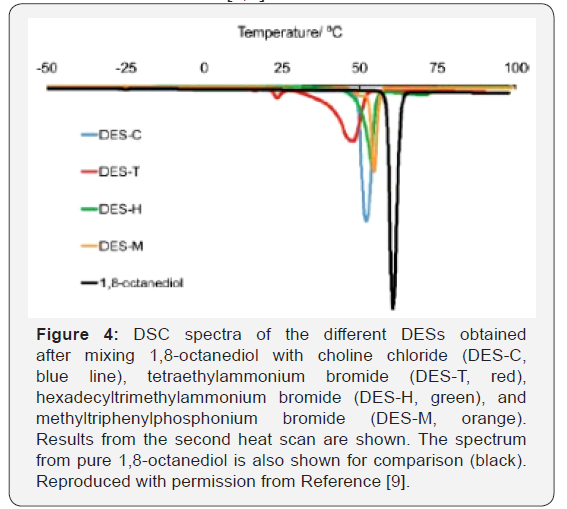

From DSC scans, the melting points (Tm) for DES-C, DES-T,

DES-H, and DES-M were identified at 52, 47, 54, and 55°C,

respectively, which were significantly below those of any of its

individual components (i.e., 61°C for 1,8-octanediol, 302-305°C

for compound C, 285°C for T, 248−251°C for H, and 230−234°C

for M) (Figure 4). Hydrogen bonding between the halide anion of

quaternary nitrogen or phosphonium salts and the 1,8-octanediol

as the hydrogen donor moiety is the most plausible explanation

for the stabilization of the different DESs formed, as previously

described for other DESs [4,7].

Polymer inhibition of bacterial growth against E. coli was

measured as the diameter of the zone of inhibition around

polymer discs normalized by the grams of polymer. A clear zone

of inhibition was observed around the discs, with values varying

from 1.76 (POC-C) to 68.90 (POC-M) mm g-1 of polymer as the

minimum and maximum inhibition zones, respectively.

DESs have been used in polycondensations, where one

of the components was also a reactant, thus called all-in-one

systems [10]. Electrochemical polymerization of conductive

monomers has also been explored taking advantage of the ionic

conductivity of DESs [11-15], including the FeCl3-catalyzed

oxidative polymerization of 3-octylthiophene [14]. Recently,

DESs were reported to play the role of curing agents in epoxy

resins [16], monomer [17,18] and initiator [19] in ring-opening

polymerization.

Free-radical polymerization of DESs: deep eutectic monomers

In free-radical polymerization of DESs, monomers able to

polymerize undergo free-radical polymerization while taking

part in a DES, as hydrogen bond donor or ammonium salt, so

called DES monomers [20]. The introduction of DESs in freeradical

polymerizations was reported by the synthesis of Poly

(Acrylic Acid) (PAAc) and Poly (Methacrylic Acid) (PMAAc)

monoliths by frontal polymerization [21]. Frontal polymerization

(FP) is normally performed with neat monomers but can be

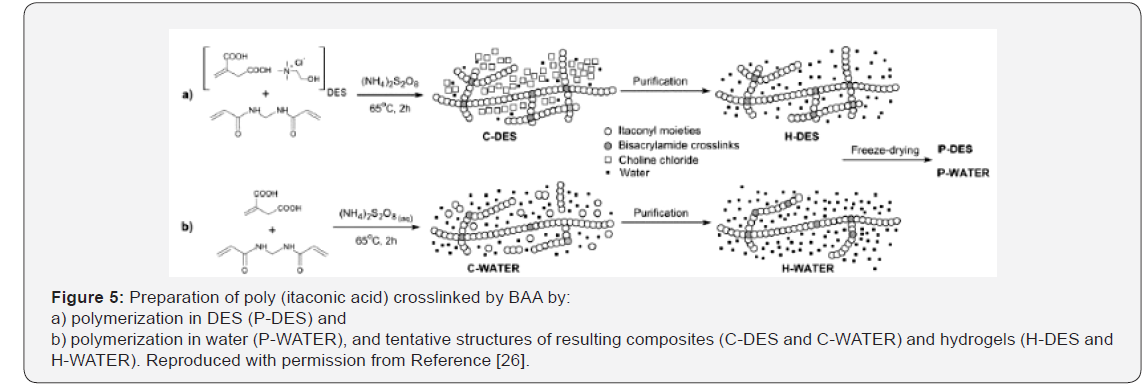

accomplished in solution [22-25]. Bednarz et al. [26], described

the free radical copolymerization of itaconic acid−forming DES

with ChCl−and AAm by in situ polymerization-crosslinking of the

DES (Figure 5). Itaconic acid is a bio-based monomer containing

an unsaturated moiety that slowly polymerizes by free radicals;

it also has two carboxylic groups available as HBDs [27]. As result

of Itaconic Acid (IA) transformation into DES, copolymerization

initiated by persulfate proceeded faster and at lower

temperature than in water and produced higher crosslinked

hydrogels, pointing to a catalytic effect of ChCl. Based on the

results of itaconic acid free-radical polymerization initiated by

Ammonium Persulfate (APS) in water, it was concluded that

DES acted as the solvent of itaconic acid and also as catalyst in

free-radical polymerization processes [26]. According to this

study, the copolymerization-crosslinking of itaconic acid with

N, N’-methylenebisacrylamide in the DES was a useful method

for the preparation of hydrogels. Comparative studies indicate

that itaconic acid undergoes faster copolymerization in DES than

in water, and probably for that reason the obtained product has

higher cross-link density [26].

DES assisted atom transfers radical polymerization

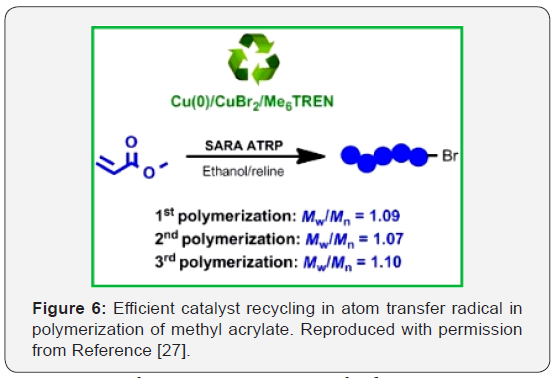

A green solvent system, composed of a eutectic mixture

(EM) and ethanol, was used in the supplemental activator and

reducing agent atom transfer radical polymerization (SARA

ATRP) of methyl acrylate (MA), yielding well‐defined polymethyl

acrylate (PMA) chains (Figure 6) [27]. In addition, this eutecticbased

system allows a straightforward separation of the entire

catalytic system, with possibility of reutilization, which is a much

advantageous feature for a possible industrial implementation

of the SARA ATRP process [27]. In this study, ethanol/reline

(choline chloride: urea) mixtures showed to be excellent solvent

for the polymerization, providing well-defined PMA (dispersity,

Ð(Mw/Mn) <1.2) as well as affording the recycling of the entire

catalytic system Cu(0)/CuBr2 /Me6TREN, which could be reused

at least two times in new SARA ATRP experiments.

Conclusion

Deep eutectic solvents provided a reaction medium, so

that polymerizations were ultimately performed in a solventless

manner. DESs also provided new precursors that favored

more efficient polymerizations by decreasing the energy input

required for the reaction to proceed. The use of mild reaction

conditions in combination with the compositional versatility of

DESs, which allows the selection of low toxic components, is also

of interest from the viewpoint of green chemistry due to it opens

up the way to the design of eco-friendly synthetic methods. DESassisted

polymer syntheses met more green principles than

those of conventional ones, so, polymers obtained from greener

processes have more opportunities to be feasible for green

applications than polymers obtained from less green ones. These

encouraging results suggest that DES-assisted polymerizations

can help to provide synthetic designs and products with a

greener character.

For more articles in Academic Journal of Polymer Science please click on:https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment