Preparation of Low Molecular Weight Glucomannan from A. Konjac K. Koch in Vietnam by Enzyme Catalyzed Hydrolysis Reaction and its Prospective use to Lower Blood Sugar Levels-Juniper Publishers

JUNIPER PUBLISHERS- ACADEMIC JOURNAL OF POLYMER

SCIENCE

Abstract

In order to break down the glycoside bond in

glucomannan obtained from the bulb of the Konjac in Việt Nam, we used

the extract from bacteria bacillus subtilis. The reaction was carried

out at 40oC for 6h, pH 5 and the E/S ratio of 0.4(w/w). The obtained

oligo-glucomannan after hydrolysis that had molecular weight lower than

1748Da was tested for glucose tolerence in experimental animals. The

test results showed that the hydrolyzed glucomannan at a dose of 6g/kg

was more effective in lowering blood glucomannan in mouse models that

were made to have blood sugar increase exogenously by oral admistration,

as compared to original glucomannan.

Keywords: Hydrolyzed glucomannan; Enzyme; Blood sugar

Introduction

Glucomannan is a water-soluble polysaccharide

consisting of D-mannose and D-glucose units linked with β - (1→ 4)

glucosidic bonds, with the degree of branching of about 8% via β-1,3- or

β-1,6-glucosidic linkages and the degree of acetylation of 5÷10%. Being

a soluble fiber, low in energy, that acts as a sweeper to prevent

cholesterol absorption into the bloodstream, glucomannan is used to lose

weight, reduce blood cholesterol, blood fat and blood sugar with very

few side effects [1,2].

Despite its hydrophilicity, glucomannan is poorly

soluble in water (solubility of around 30%) due to its high molecular

weight, which limits its application range in certain areas [3]. In

order to increase its solubility, glucomannan is hydrolyzed to lower its

molecular weigh and the process attracts the attention of many

scientists. Studies on the methods of preparing low molecular weight

glucomannan have been of interest to many authors worldwide, including

enzymatic hydrolysis [4,5]. treatment with hydrochloric acid combined

with ultrasound [6], hydrolysis under the effect of gamma-ray combined

with ethanol [7], treatment with gamma-ray combined with H2O2 [8],

alkaline hydrolysis combined with heat [9]. With superior catalytic

activity compared to chemical catalysts and high biological safety,

enzymes have brought many great achievements in several fields such as

industry, agriculture, pharmaceutical chemistry, etc. As a result, the

exploitation and use of enzymes are being considered by many

countries in the world. The work by Wenjie Jian et al investigated the

Konjac glucomannan hydrolysis reaction with γ rays combined with

Endo-(1, 4)-mannanase enzymes, yielding a product with molecular weight

lower than 2200 Da [6].

Cheng YU Chen et al. [5] also carried out the

hydrolysis reaction of glucomannan with β mananase enzyme, lowering the

molécular weight to 3089 Da [10]. In this study, we conducted the

hydrolysis reaction of glucomannane obtained from the bulbs of Konjac

grown in Vietnam by the enzyme produced by the bacteria bacillus

substilis. The hydrolyzed product was tested for blood glucose tolerence

in experimental mice.

Experimental

Materials & chemicals

Purified glucomannan from A. KONJAC K. KOCH in

VIETNAM was prepared iou laboratory [11]. Enzyme endo-1,4 β-Mannanase

(Bacillus sp.) EC 3.2.1.78 CAZy Family: GH26 CAS: 37288-54-3 was from

Megazyme Company, all other chemicals were obtained from Merck, used

immediately without purification.

Research methods and equipment

Enzyme from bacteria Bacillus subtilis

Among amylase-producing microoraganisms, Bacillus

subtilis is a thermophilic bacterium able to grow rapidly (4-6 times

faster than moisturephilic bacteria) and grows well at relatively high

temperatures. Therefore, its culture is less likely to be infected by

other microoraganisms.

Bacillus subtilis belongs to: Order: Eubacteriales Family:

Bacillaceae Genus: Bacillus Species: Bacillus subtilis

It is an aerobic microorganism with optimum temperatures

for growth in the range from 36oC to 50oC, the maximum of about

60oC, the spores can resist relatively high heat. In the extract of

Bacillus subtilis there are various enzymes, including β-amylase,

cellulase, capable of hydrolyzing β - (1→ 4) glucosidic linkages in

glucomannan [12].

Hydrolysis of Glucomannan

The proper digestive environment for decomposing

polysaccharides is slightly acidic and the body temperature is

within the enzyme’s active temperature range. We carried out the

reaction as follows:

a) Weigh about 10g of substrate for each sample

b) Disperse glucomannan in 300ml H2O, adjust the solution

pH to 5 with HCl. Add 4ml enzyme extract to the solution.

Agitate the mixture to homogenous solution.

c) Incubate the mixture in a warm cabinet at 40oC for 24h.

d) At the end of the reaction, add excess absolute ethanol

to the mixture, centrifuge at 9000 rpm. Remove the liquid,

vacuum dry at 50oC to constant weight. The obtained product

was hydrolyzed glucomannan, named as LMWG-S.

Blood glucose tolerance of the product

The ability to stimulate blood glucose tolerence of the

hydrolyzed product was determined in normal, healthy mice by

oral glucose tolerance test (OGTT). The test mice were white mice

(of Swiss strains), both male and female, weighing 18-22 grams,

having healthy physiology.

The mice were fed daily with synthetic feed supplied by

the Institute of Vaccines and Biologicals. They were exposed to

light from 12am to 12pm. The mice were divided into test lots,

each with 10 individuals. After stable culture under laboratory

conditions, the mice were tested for blood glucose tolerence by

taking the following preparations:

a) Test lot 1 (control): distilled water.

b) Test lot 2: hydrolyzed glucomannan at a dose of 3g/kg

body weight.

c) Test lot 3: hydrolyzed glucomannan at a dose of 6g/kg

body weight.

d) Test lot 4: glucomannan at a dose of 6g/kg body weight.

e) Test lot 5: gliclazide at a dose of 10mg/kg body weight.

f) Just after the mice were given the preparations, the

blood glucose level was measured (0h).

g) After 2h the mice were fed with glucose at a dose of 2g/

kg body weight to increase blood glucose.

h) Measure blood glucose levels 2h, 2h30, 3h và 4h after

taking the preparations.

Results

(LMWG-S)

The obtained product after the hydrolysis reaction of

glucomannan was a translucent white, water soluble powdered

mass that could be finely ground. The yield reached 65%.

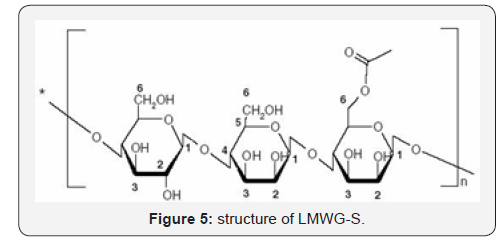

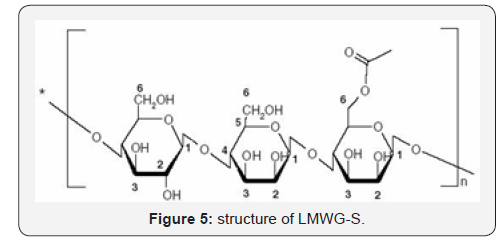

Structure and properties of LMWG-S

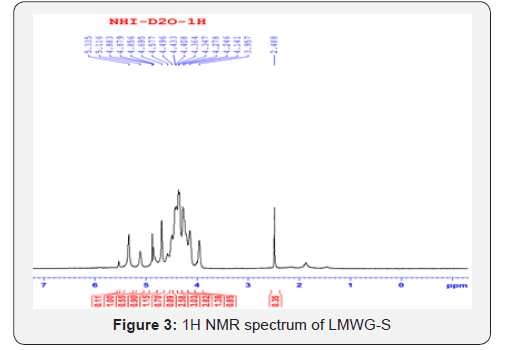

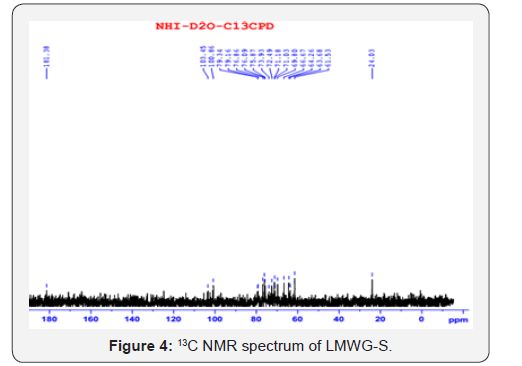

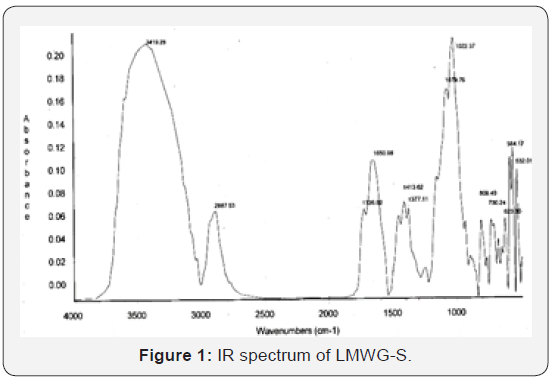

The spectra of IR, NMR, TGA of the product are shown in

(Figures 1-5).

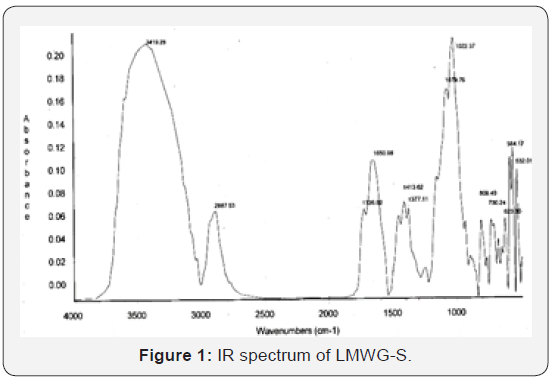

The typical peaks on the IR spectrum of the product (Figure

1) are inferred as follows: the area 3000-3700cm-1 represents

the covalent vibration of the hydroxyl group (-OH); 2887cm-

1 represents the covalent vibration of the CH linkage (υC–H);

1726cm-1 represents the covalent vibration of the carbonyl

group (υC=O); 1650cm-1 represents the presence of absorbed

water molecules; 1413 and 1377cm-1 represent the deformation

vibration of the CH linkage (CH); 1150cm-1 represents the

covalent vibration of the ether linkage C-O-C between units in

polysaccharide macromolecule; 1079 and 1022cm-1 represent

the covalent vibration of the C-O linkage of the C-OH group. The

peaks in the area 808÷900 cm-1 represents the α pyranose ring

of glucose and mannose. Thus, the chemical structure of the

hydrolyzed glucomannan is virtually unchanged from the original

glucomannan. This may result from the fact that the hydrolysis

reaction under the experimental conditions takes place mainly at

the 1-4 glycosidic linkage.

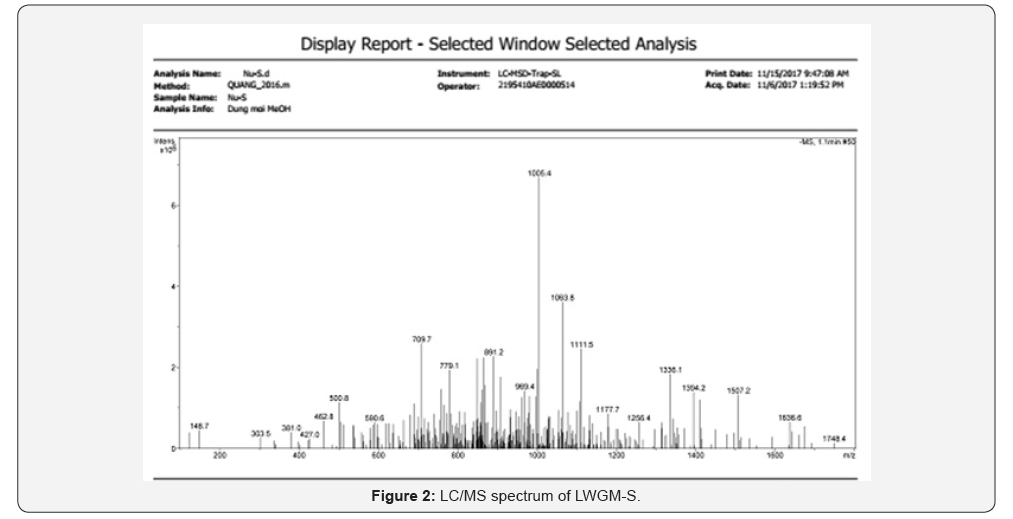

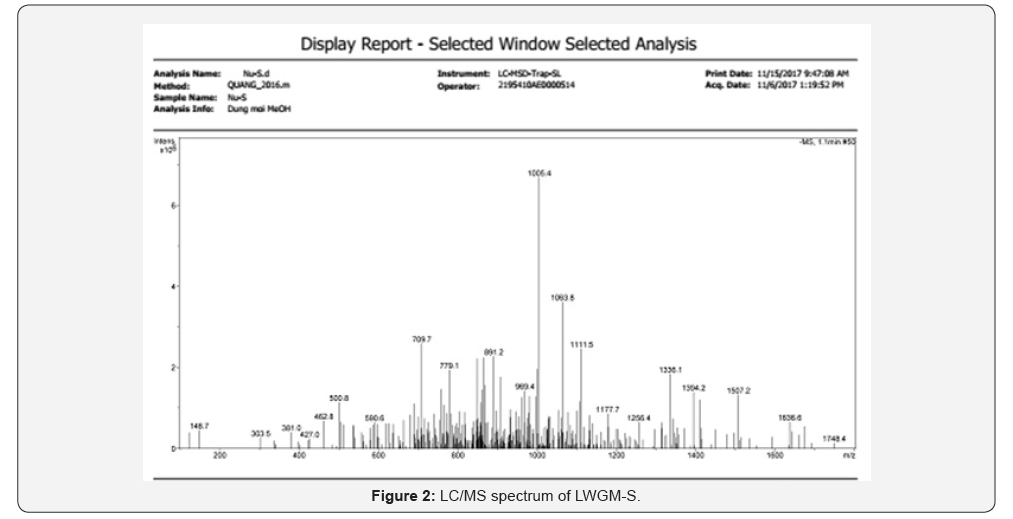

As shown in Figure 2, the hydrolyzed product mixture has

the maximum molecular weight of 1748.4Da. The molecular

weight of glucomannan is reduced to 1748,4Da, which proves the

effectiveness of the experimental model. The optimal conditions

for hydrolysis are similar to the results reported by Cheng YU Chen

et al. [13]. However, the hydrolysis process of our experimental

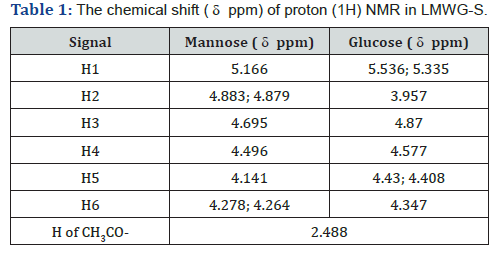

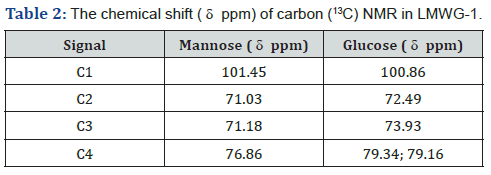

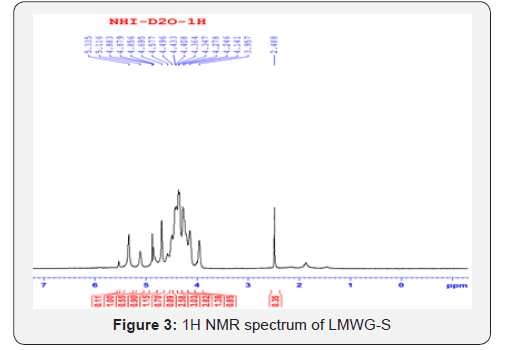

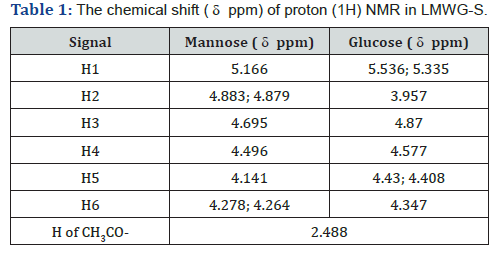

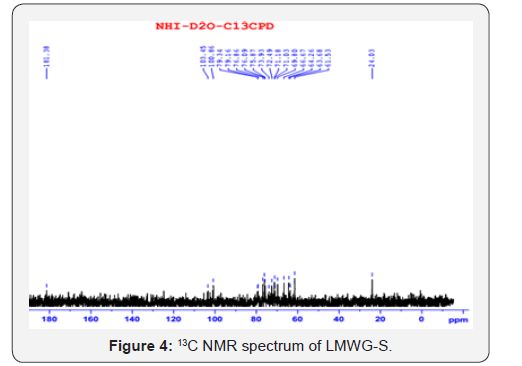

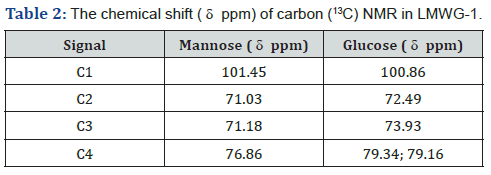

model results in oligo glucomannan with lower molecular weight.The chemical shift ( ppm) of 1H and (13C) in konjac glucomannan

molecules is shown in Tables 1 & 2, respectively [14-19].

The M/G ratio is calculated as follows:

This result shows that the M/G ratio of the hydrolyzed product

is slightly lower than that of the original GM (RM/G 1.6) [3].

The result shows that DA of the hydrolyzed product is lower

than that of the original raw material, proving that together with

the hydrolysis reaction at the 1,4-β-D glycosidic linkage, de-Nacetylation

also occurred, which leads to DA decrease of the

product

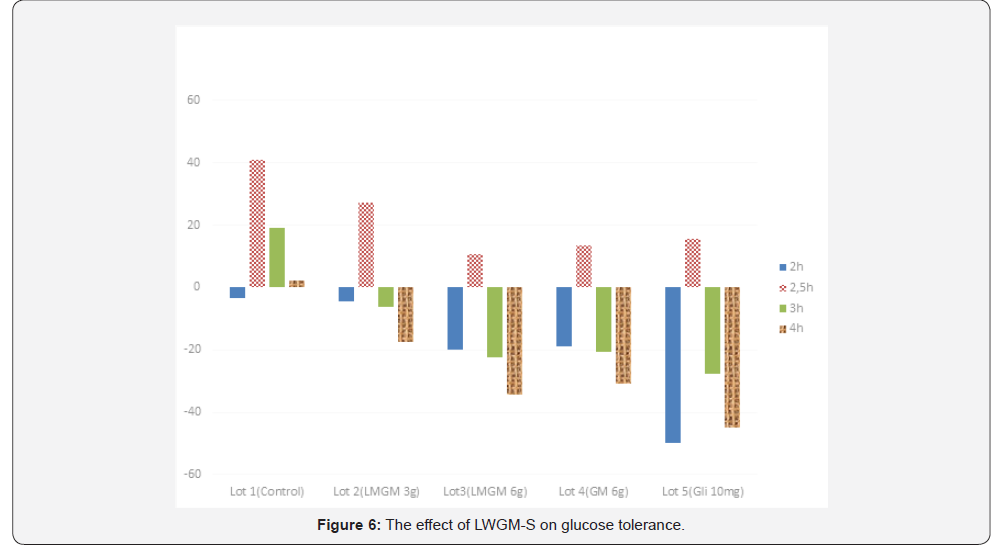

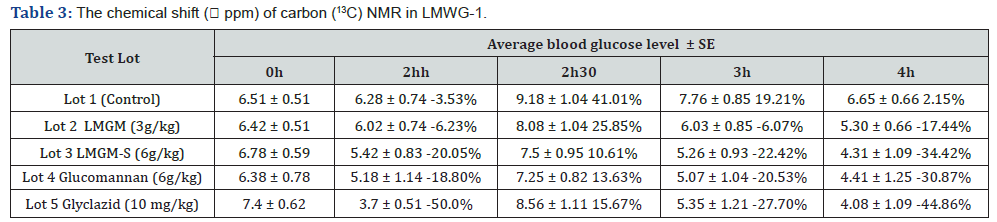

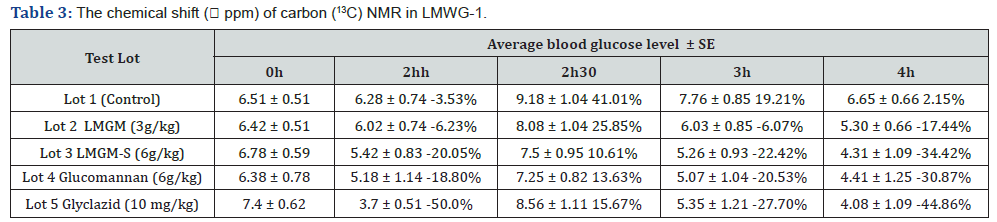

Blood glucose tolerance of the product

The blood glucose tolerance test is an experimental

method

often used in recent studies in Vietnam and in the world. There are also

studies that attemp to test the inhibition of glucose absorption

in the intestine through food or glucose solution. However, this

study focuses on the cellular glucose tolerence, an important

indicator to assess the effects of diabetes medications. The effect

of the product on blood glucose tolerence is demonstrated by

changes in blood glucose level of mice after administration of

2mg/kg body weight. The research results are shown in the Table

3 below

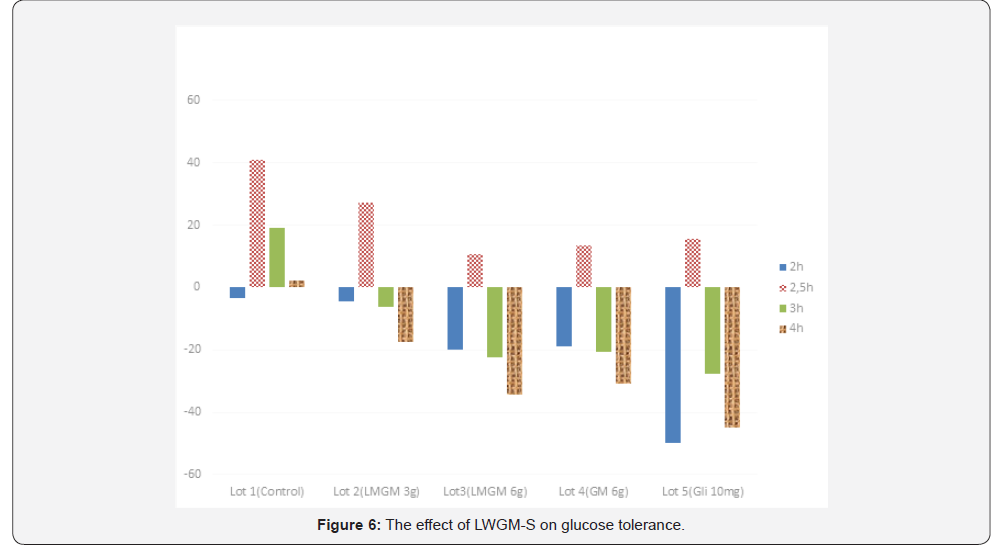

The results from Table 3 and Figure 6 show that at the time of

glucose feeding (2 hours after taking the preparations), all the test

lots had a reduced blood glucose level, due to fasting. At the time

2.5 hours after taking the preparations because the mice were

fed with glucose at a dose 2g/kg body weight, the blood glucose

level in all lots increased (and reached the maximum). This level

gradually decreased at the time 3 and 4 hours after glucose

feeding. At the time 2.5 hours after the feeding, lots number 2, 3,

4 and 5 had lower blood glucose increase than lot 1 (as control),

the difference is statistically significant (P≤ 0,05). Three and four

hours after taking the preparations, lots number 2, 3, 4 and 5

had greater blood glucose reduction than lot 1. The difference is

statistically insignificant (P>0,05) on the blood glucose reduction

percentage between lot with gliclazide (lot 5) and lot with

glucomannan (at 6g/kg) and lot with hydrolysed glucomannan

(at 6g/kg). This proves that hydrolysed glucomannan (at 6g/kg

body weight) is capable of boosting cellular glucose tolerance. At

the times 3 hours and 4 hours after taking the preparations at a

dose of 3g/kg, the blood glucose reduction percentage was lower

than that of the lot with a dose 6g/kg of original glucomannan.

This difference is statistically significant, which proves that the

stimulation of glrsucose tolerence of hydrolysed glucomannan

at the dose of 3g/kg is ineffective. 3 hours and 4 hours after

taking the preparations, the blood glucose reduction of the lot

with hydrolyzed glucomannan is greater than that of the lot with

original glucomannan.

This difference is statistically significant with P<0,05. This

proves that the hydrolyzed product can stimulate the glucose

tolerance better than the original glucomannan. There are two

possible explanations: stimulation of glucose tolerance occurs

in brain, liver and red blood cells (cells that can receive glucose

without requiring insulin); or stimulation of insulin secretion,

increased insulin sensitivity of the preparations to target tissues

results in glucose tolerance of the target cells (hepatocytes,

muscle and adipose tissues, etc.). Whichever mechanism, this is

significant in the blood glucose reduction treatment for patients

with diabetes.

Conclusion

We have prepared low molecular weight glucomannan from

the bulbs of A. Konjac K Korch in Vietnam and demonstrated

the structure of the obtained product. The hydrolyzed product

has molecular weight of less than 1748,4Da and degree of

acetylation lower than the original glucomannan. The hydrolyzed

glucomannan at the dose of 6g/kg is more effective in reducing

blood glucomannan in mouse models that were made to raise

the blood glucose levels exogenously by oral administration, as

compared with the unhydrolyzed original glucomannan.

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment