Nickel and Palladium Catalyzed Olefin Polymerization-Juniper Publishers

JUNIPER

PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

This review summarized the progress on transition

metal catalysts for olefin polymerization, and focuses on the olefin

polymerization by the late transition metal catalysts and the recent

advances in catalyst design. In recent years, nickel and palladium

complexes for olefin polymerization have received extensive researches

owing to the precise control of branching microstructure, molecular

weights and properties of the resulting polyolefins.

Keywords: Nickel and palladium complexes; Olefin polymerization; Chain-walking; Branched polymer

Abbrevations:

MAO: Methylaluminoxane; CGC: Constrained Geometry Catalysts; LDPE: Low

Density Polyethylene; LLDP: Linear Low-Density Polyethylene; HDPE:

High-Density Polyethylene; PP: Polypropylene

Introduction

The research of the ethylene and α-olefins

polymerizations using late transition metal catalysts should be

highlight for development of polyolefin materials during the past two

decades [1-5], because polyolefin materials are tremendously important

in daily life [6]. Branched polyolefins are generally produced by

transition-metal catalyzed copolymerization. The physical properties of

polyolefin materials can be dramatically affected by their

microstructures, which are controlled by the catalyst structures and

their catalytic behavior. Progress of molecular the catalysts of

transition metal complexes during these three decades enabled control of

stereochemistry of poly(α-olefin)s, control of molecular weight of

polyethylene and poly(α-olefin)s, synthesis of block copolymers by

living polymerization, and copolymerization with various comonomers

including polar functionalized olefins [5]. Thus, the design and

synthesis of novel transition metal catalyst has always been a research

focus of the polyolefin research.

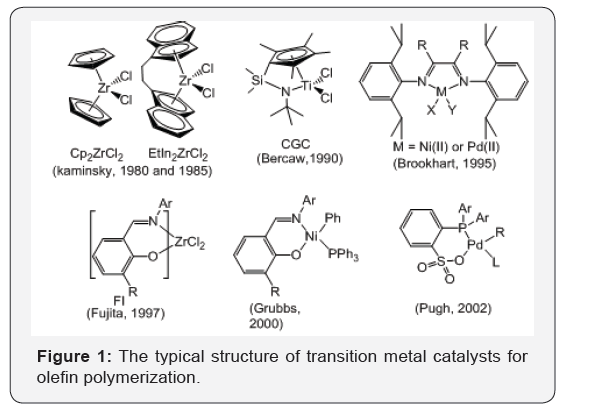

In 1950s, Ziegler & Natta discovered that the

mixture of titanium chloride and alkyl aluminum compounds enabled

polymerization of ethylene and propylene, the synthesis of High Density

Polyethylene (HDPE) and isotactic polypropylene, respectively. The

discovery of [7] catalysts (Figure 1) not only revolutionized polyolefin

production, but also catalyzed the development of the entire

organometallic chemistry field.

In 1980s, Kaminsky [8] discovered that Methyl

Aluminoxane (MAO) as an excellent co-catalyst to highly activate

half-metallocene’s [8] and badged metallocene catalysts for alkene

polymerization to produce polymers of narrow molecular weight

distribution. The second milestone in alkene polymerization catalysis

was the development of metallocene catalysts.

In 1990s, Bwren reported that the constrained

geometry catalysts (CGC, Figure 1) [9] exhibited their unique properties

in the catalysis and revealed the relationship between the structure of

the catalysts and stereoselectivity of the reaction, and showed

high activity for ethylene and 1-alkene copolymerization. In

addition, Fujita also reported that the bis(imine-phenoxy) titanium

and zirconium complexes (FI catalysts, Figure 1) exhibited high

activity for ethylene polymerization [10].

In 1995, Brookhart [11] discovered that nickel and palladium

complexes with bulky diimine ligands showed high catalytic

activity for ethylene and α-olefin polymerizations [11] to produce

high molecular weight polyethylene with different polymer

topologies and branched poly(α-olefin)s [12-13]. Interestingly,

these nickel and palladium catalysts are also used for

copolymerization of ethylene with polar monomers to afford the

copolymers possessing functional groups in a single step because

of their good tolerance toward polar functionality [14,15].

The discovery of late transition metal nickel and palladium

catalysts has initiated a new olefin polymerization field. In

1998, Gibson [16] and Brookhart [17,18] reported that Fe

and Co catalysts with bis (imino) pyridine catalyzed ethylene

polymerization efficiently to afford linear polyethylene. In 2000,

Grubbs [19] reported that neutral nickel catalysts [19] containing

salicylaldimine ligand are used for polymerization of ethylene. In

2002, Pugh [20] reported that palladium catalysts with phoshine

sulfonate ligand can produce unique polymers such as a highly

linear copolymer of ethylene and alkyl acrylates [20] and a nonperfectly

alternating copolymer of ethylene and CO [21].

In this review, recent progress on late transition metal

catalysts for ethylene or α-olefin polymerizations are summarized

[1]. Systematical study elucidated the effects of late transition

metal ion, α-diimine backbone and the ligand on it, the effects

of polymerization conditions (temperature and pressure) on the

catalyst’s performance, branching degree, molecular weight and

its distribution of the polymer and the properties of the polymer

produces.

Chain-walking ethylene polymerization by nickel and palladium catalysts

The research of the ethylene polymerization catalyzed by late

transition metal catalyst should be highlight for development of

polyolefin materials in recent years [22-28], because polyethylene

is probably the polymer you see most in daily life. There are three

main types of polyethylene namely: Low Density Polyethylene

(LDPE), Linear Low-Density Polyethylene (LLDP) and High-

Density Polyethylene (HDPE).

Chain-walking ethylene polymerization mechanism

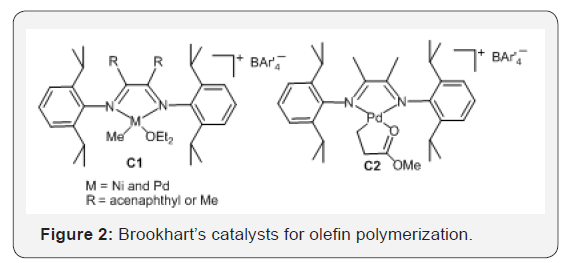

The discovery of nickel and palladium α-diimine catalysts

(Figure 2) by Brookhart et al. [11] in the 1990s is another further

major advance in the alkene polymerization catalysis [11-13].

Distinctly different from other catalysts, this unique series of late

transition metal catalysts is featured with their characteristic

chain-walking mechanism and allow the unprecedented one-step

synthesis of polyethylenes with controllable chain topology [29-

33].

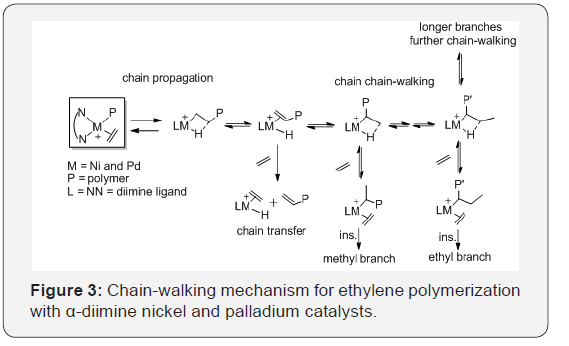

The nickel and palladium α-diimine catalysts C1 and C2

(Figure 2) showed high activity for polymerization to produce

different branched polymers, depending on the catalyst structures

and the polymerization conditions (temperature and ethylene

pressure), because the the ability of the propagating metal-alkyl

species to migrate along the growing polymer chain via rapid

β-hydride elimination and reinsertion (chain-walking, (Figure 2)

[34-37]. The formation of the major types of branches including

the methyl, ethyl, propyl, butyl, sec-butyl and longer chains, in the

branched polyethylene [36,38]. The mechanism of chain-walking

for ethylene polymerization is shown in (Figure 3).

The degree of the polyethylene branching can be controlled via

polymerization conditions [1,39] as follows. For example, Guan et

al. [40,41] demonstrated that ethylene pressure has been used to

control the competition between monomer insertion and chainwalking

processes for ethylene coordination polymerization

catalyzed by a palladium α-diimine catalyst C2. The topology of

the polyethylene changed from linear polyethylene with moderate

branches at high ethylene pressures to a hyperbranched

polyethylene at low pressures.

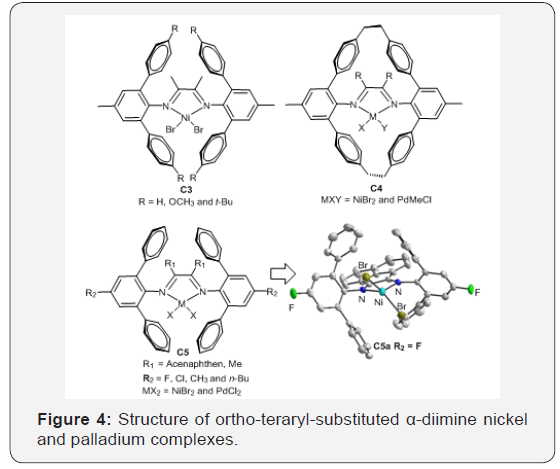

Modified nickel and palladium catalysts

Previous studies showed that sterically bulky ligands

are usually required to afford nickel and palladium catalysts

capable of generating high activity, stability and high molecularweight

polymers [42-48]. Besides, linear polyethylene via chain

straightening mechanism is the most abundantly produced plastic

owing to its inexpensive monomer, thermoplastic properties,

and semi-crystalline nature [1]. The degree of the polyethylene

branching can be controlled via catalyst structures and

polymerization conditions. For example, Schmid et al. [49] reported

a new “Ortho-Aryl Esffect” using terphenyl substituted 1,4-diaza 1,3-butadiene ligands: the corresponding nickel complexes C3

were highly active catalysts for ethylene homopolymerization to

produce almost perfectly linear polyethylene’s in the presence of

hydrogen [49].

Guan et al. [50-52] designed the macrocyclic ligand by

connecting the aryl substituents of 2,6-diarylphenylimino

moieties using ethylene tether. Their cyclophane-based nickel

and palladium catalysts C4 showed significantly higher thermal

stability than the acyclic analogs [49-52]. The palladium catalysts

also generated polymers with significantly high branching

density compared to the acyclic counterparts, suggesting faster

chain-walking process [50]. The cyclophane-based nickel catalyst

promoted living polymerization of propylene even at 50–75°C [51].

This type of catalyst enhances both the 2,1-insertion of propylene

and the chain-walking reaction. The branching density of the

generated Polypropylene (PP) is slightly above 100/1000C, which

is only half of the value comparing with conventional α-diimine

nickel catalyst. Besides, the palladium catalyst incorporated a

much higher amount of Methyl Acrylate (MA) than the acyclic

analogue (Figure 4).

Inspired by these works, we recently reported a series of

α-diimine nickel and palladium complexes C5 [53,54] containing

2,6-diphenyl groups. These nickel complexes exhibited high

catalytic activity in the polymerization of ethylene (up to 106g PE/

(mol Ni h bar)) and produced highly-branched polyethylenes at

high temperature upon activation with Et2AlCl. The introduction

of an electron-withdrawing group to the ligand framework

improves the catalytic activity significantly. We also reported a

series of α-diimine nickel complexes [35,37,42] containing paraphenyl

or para-naphthyl substituents for ethylene polymerization

under low ethylene pressure. These nickel complexes also

exhibited high catalytic activity and produced highly-branched

polyethylenes.

Brookhart et al. [55] reported a “sandwich” α-diimine nickel

catalyst C6a incorporating two 8-p-tolylnaphthylimino groups

which provide exceptional shielding of the two axial sites

were shown to produce highly branched polyethylene (up to

152 branches/1000C) [55] with ultra-high-molecular-weight.

Recently, they also studied a “sandwich”-type diimine palladium

catalyst C6b for ethylene polymerization, the catalyst conducted

living polymerization at 25°C and produced hyperbranched

polymers [56] (Figure 5).

Coates et al. reported that the precision chain-walking

polymerization of higher α-olefins using the “sandwich” α-diimine

nickel catalyst C6c [57] and some derivative catalysts to afford

highly “chain-straightened” semicrystalline polymers (Tm >

100°C) with a significant fraction of 1, ω-enchainments. We

have reported that a similar naphthyl-α-diimine nickel catalyst

C7 bearing chiral bulky sec-phenethyl groups in the o-naphthyl

position, activated by Et2AlCl [58], showed highly catalytic

activity for the polymerization of ethylene (2.81 × 106 g PE (mol

Ni h bar) −1) and produced branched polyethylene. Interestingly,

C7 could Produce Syndiotactic PMMA at low temperature (rr up

to 88.75%, -30°C).

Conclusion

In this review, the progress on transition metal catalysts

for olefin polymerization were summarized. We first briefly

discussed the chain walking mechanism of nickel and palladium

catalysts in ethylene polymerization. Subsequently, some recent

advances in the α-diimine-based nickel and palladium catalysts

development were summarized. Specifically, the modifications on

N-aryl substituents were described.

Acknowledgements

This work was supported by the National Natural Science

Foundation of China (NSFC, 21801002), and the Natural Science

Foundation of Anhui Province (No. 1808085MB47).

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment