Research of Hydrogen Absorption-Desorption by Ti-Al-Nb Alloy-Juniper Publishers

Authored

by Kurbanbekov ShR

Abstract

The paper presents kinetics of hydrogen sorption of

Ti-23.5at%Al-21.5at%Nb alloys in isothermal conditions underthe

temperature of 450, 500 and 550 °С. It was determined that maximum

quantity of absorbed hydrogen is observed at material of sorbed alloy

under the temperature of 550 °С. That presents approximately 0.289mass%.

It had been found that hydrogen is released under the temperatures

within 700 …790 °С. In addition, it was revealed that maximum release of

hydrogen composes 85% of samples saturated under the temperature of 550

°С.

Keywords: Intermetallic compound; Absorption-desorption; Hydrogen; Plasticity; CrucibleIntroduction

As is known, to find a safe method for reversible

hydrogen storage is currently one of the important issues in the field

of hydrogen energetics. Storage of the hydrogen in various hydrides of

metals and alloys is one of the advanced methods to solve this issue

[1]. Application of alloys for hydrogen storage and its use depends on

several tasks, which focused on increasing of sorption properties and

cyclic stability of alloys. Ti-Al alloys are one of the efficient

materials for storage of hydrogen [2,3]. Using of alloys to storage

hydrogen and its use depends on several tasks, which are to increase the

sorption properties and cyclic stability of alloys. Alloys based on

Ti-Al are one of the most effective materials for hydrogen storage

[2,3]. It is known that, additional introduction of niobium into the

Ti-Al system significantly increases the plasticity of Ti3Al,

intermetallic which can be explained by a decrease in the degree of

ordering and decrease in the share of covalent bond [4]. Also,

additional introduction of niobium into the Ti-Al system [5,6] leads to

an increase in its absorption-desorption properties of hydrogen due to

the formation of nanoscale phases having less dense packaging compared

to the face centered close-packed lattice of Ti3Al.

The purpose of this paper is to determine the optimal absorption-desorption temperatures of hydrogen to the sample

materials based on Ti-Al-Nb system and to study the changes in its structural-phase state.

Materials and Methods of Research

Ti (99.9%), Nb (99.96%) and Al (99.98) powders were used as initial raw materials for producing Ti-Al-Nb-composite.

Technology of sparkplasma sintering (SPS-technology)

of powder mixtures was used to create compact samples based on

intermetallic Ti-Al-Nb system. Sintering of powder mixtures was

conducted on a special facility Labox-1575. Research of hydrogen

sorption kinetics by intermetallic compounds of Ti-23.5at%Al-21at%Nb

system was conducted on an experimental facility VIKA [7] under the

temperatures of 450, 500 and 550°С. The facility consists of a working

chamber, pumping system and information-measuring system (IMS).

Differential pumping system including forevacuum pump NVR-5DM with a

nitrogen trap and two magnetic discharge pumps NORD-100 and NORD-250 was

used to ensure the required pressure in the working chamber of the

facility. Forevacuum pump is used to pre-pumping of gases from the

working chamber after loading the sample into the crucible, magnetic

discharge pump NORD-250 is used for pumping the working chamber and the

measuring path in the annealing process after loading samples, the pump

NORD-100 is used to create high vacuum in the chamber and the measuring

part of the experimental facility during the experiment. The

experiments consisted the following: Ti-23.5at%Al-21at. %Nb

sample was loaded in a special ampoule device (AD). After

loading of the sample, the high–temperature decontamination

of AD cell with the samples was conducted for 30 minutes at

a temperature of 800-850°C and a constant pumping of the

AD volume by a turbomolecular pump were conducted. Then

the body of the AD experimental cell was cooled down to the

studied temperature (the temperature of hydrogen saturation)

and spectrally pure hydrogen was injected with samples to a

given pressure in the volume of AD. Further, pressure change

in the AD volume with studied samples was recorded under the

preset saturation temperature using a deformation pressure

sensor. After that, the heating of ampoule device with samples

was stopped, and the samples were cooled in the hydrogen

atmosphere to room temperature. After 12 hours, samples were

heated again to a preset saturation temperature and kept under

this temperature shelf for 15-20 minutes, after which samples

were cooled to room temperature, and remaining hydrogen was

pumped from the volume of the ampoule device.

Research Results and Discussion

The main criteria that determine the prospects of application

of those or other materials for storing hydrogen, typically consider

the amount of their sorption capacity, operating temperature

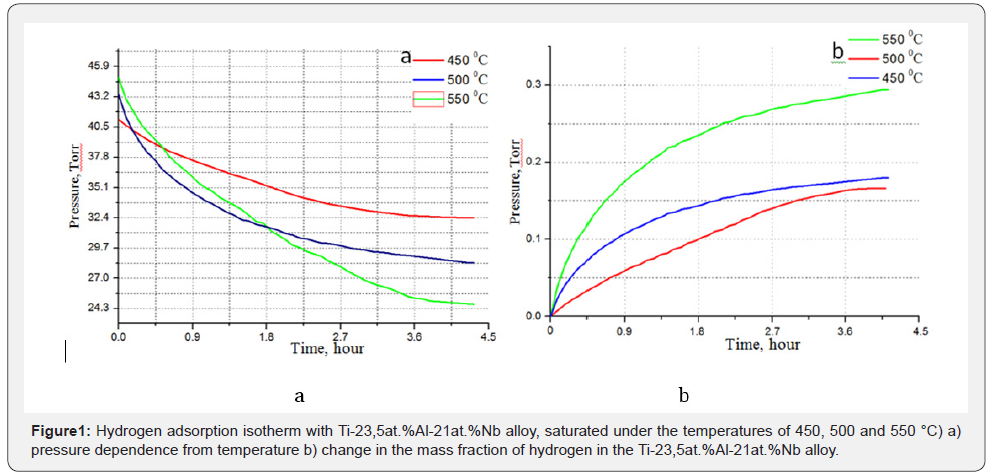

and pressure, kinetics of the interaction [8]. Сurves of hydrogen

sorption by Ti-23.5at.%Al-21at%Nb alloy under temperatures

of 450, 500 and 550°C and a pressure of 41 Torr (Figure 1) were

presented to compare processes of sorption isotherms. Figure

shows that under the increase of temperature from 450°C to

550 °C, an increase in the rate of hydrogen sorption occurs and

respectively, the change in pressure of the ampoule (Figure 1a)

is observed. Figure 1b shows the mass fraction of hydrogen

absorbed by the sorbent at temperatures of 450-550 °C.Figure

1b shows that there is an intensive absorption of hydrogen at a

temperature of 550 °C, the proportion of hydrogen absorption

reaches up to 0.289 mass.%. Probably, the interaction of Ti2AlNb

phases with hydrogen occurs firstly, traces of which are present

in the samples, thus the activation barrier of the reaction of the

material main phases is decreased.

The ampoule device was annealed at a temperature of 900

°C for 30 minutes, before the experiment of desorption with an

empty ampoule device. Argon was injected to one atmosphere

after walls of the ampoule device cooled to a temperature of

20 °C in the volume of the ampoule device, then the ampoule

device was closed, and the ampoule volume was pumped to a

pressure of 10-4Torr, after which the ampoule device was tested

for tightness using RGA-100 quadrupole mass spectrometer and

the helium. Further, the desorption process of hydrogen by Ti-

23.5at%Al-21at%Nb alloy was conducted. The heating was from

20 to 790 °C.

In the result of conducted experiments, the dependence

of the hydrogen pressure from the sample temperature at an

increase up to 790 °C (Figure 2) was obtained. Results of the

study of Ti-23.5at%Al-21at%Nb alloy desorption showed that

hydrogen release was observed in the temperature range of 700

... 790 °C. Maximum hydrogen content in the sample saturated

at 550 °C was 0.289 mass.%. Figure 2b shows that the hydrogen

release from a sample saturated at a temperature of 550 °C

reaches up to 85%.The active yield of hydrogen is observed at a

temperature of 750 °C.

The paper [9] presents the dependence of the desorption

pressure for some systems, which shows that hydrides based

on alloys of intermetallic compounds can be used to accumulate

hydrogen in a fairly wide range of temperatures and pressures.

The main factor limiting the rate of hydrogen release and

absorption by the accumulator, in most practically important

cases, is the heat and mass transfer in the layers of intermetallic

particles, and not the sorption-desorption kinetics on individual

particles [10].

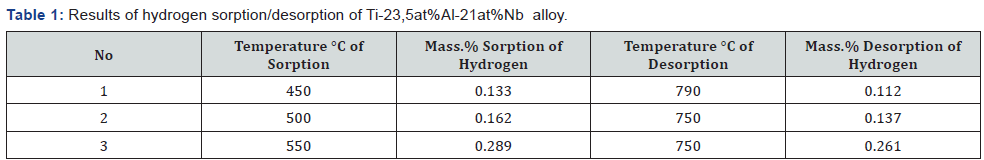

The results of the study of hydrogen-adsorption properties

showed, that the pressure of hydrogen desorption increases

sharply at 500 °C. Thus, Ti-23.5at%Al-21at%Nb alloy is a high

temperature getter. Results of the study of hydrogen desorption

are presented in Table 1.

Thus, it was found that the rate of sorption/desorption

of hydrogen depends on the heating temperature. It is also

important to note that the orthorhombic phase of Ti2AlNb is a

well hydrogen absorber. This is confirmed by the absorption of

hydrogen at a sufficiently low pressure (about 45 Torr.), and can

be explained by the acceleration of diffusion in the Ti-Al system

by doped Nb.

Conclusion

Based on the analysis of the results, following conclusions

can be made:

a) The kinetics of hydrogen sorption by Ti-23.5at%Al-

21.5at%Nb at isothermal conditions under temperatures

of 450, 500 and 550 °C is studied. The dependence of the

mass fraction of hydrogen in the material samples from

temperature was obtained.It is determined that the maximum

amount of about 0.289 mass% of absorbed hydrogen is

observed in the material sorbed at a temperature of 550 °C;

b) It had been found that hydrogen is released under the

temperatures within 700 …790 °С. At the same time, the

chemical composition of the material samples practically does not affect the temperature modes of hydrogen release.

It was found that the maximum 85% of hydrogen release is

observed in saturated at a temperature of 550 °C.

For more

details Journal of Polymer Science please

click on: https://juniperpublishers.com/ajop/index.php

To read more…Full Text in Juniper Publishers click on https://juniperpublishers.com/ajop/AJOP.MS.ID.555562.php

Comments

Post a Comment