A Review on Plastic Behavior of Polymer Sheets and Forming Process-Juniper Publishers

Authored

by Eun Ho Lee

Abstract

This paper presents a mini review about plastic

behaviour of polymer sheets. The fundamental of plasticity and concept

of constitutive modeling are introduced. As an application of the

plastic behaviour, studies on forming process of polymer sheets are

presents. Finally, the future woks are also discussed in the conclusion

section.

Keywords: Polymer; Plastic behaviour; Forming; Target temperature; Lightweight; Metal flow

Introduction

Polymer is one of widely used material due to the

great availability and low cost. For mass production, moulding and

extrusion technologies have been widely employed for polymer processing

in industries [1]. Recently, automotive industries are trying to reduce

the weight of the vehicles for improving the fuel efficiency [2]. For

the reason, they have an interest in polymer materials, and many

researchers have studied mechanical behavior of polymer materials.

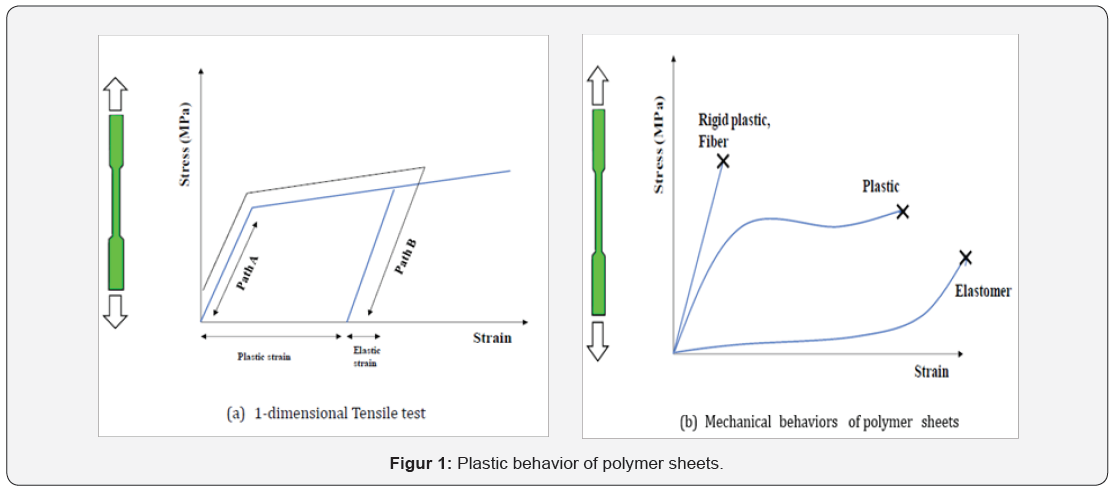

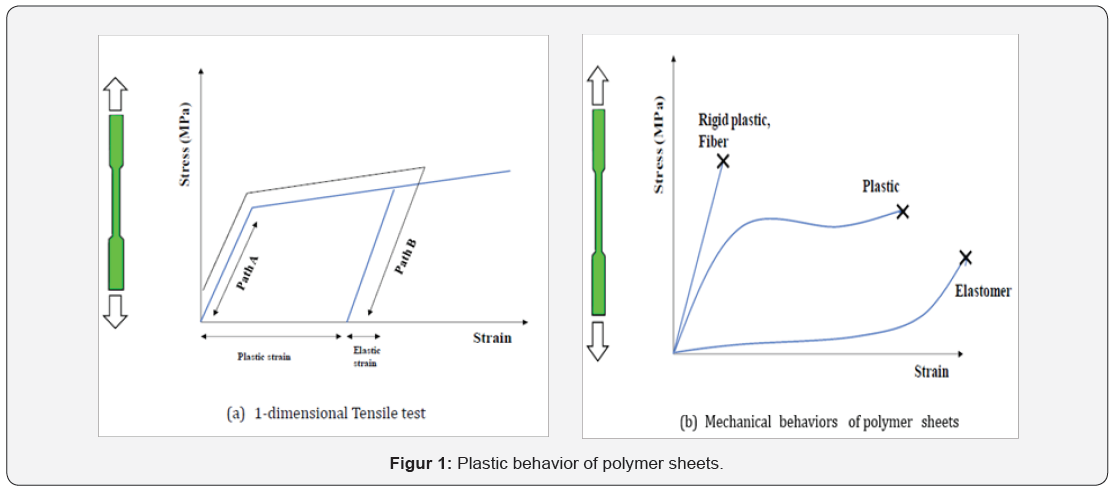

Figure 1(a) shows an example of 1-dimensional tensile test which is the

most widely used material testingmethods to obtain the material’s

behavior. When a material is getting deformed, the material has

aproportional relation between stress and strain within a range of

strain and this proportional relation iscalled elastic modulus. This

strain rage is called elastic range and the stress is called yield

stress. In theelastic range, the deformed material can recover the

original shape, as shown in the path A. However, if thestrain level is

over the elastic limit, a permanent deformation remains on the material

even though thematerial slightly recovers the strain [3,4]. This

recovered strain is called elastic strain, and the permanentdeformation

is called plastic strain, as shown in path B of Figure 1(a). Figure 1(b)

shows general behaviors ofpolymer

materials. The elastic behavior is almost the same for all the

materials. However, right after theelastic limit, rigid plastic easily

leads to a material failure while other materials have more margin

to bedeformed. For the reason, rigid plastic material does not

show plastic behavior. This break point determinesthe elongation,

the ration between the deformed length and the original length

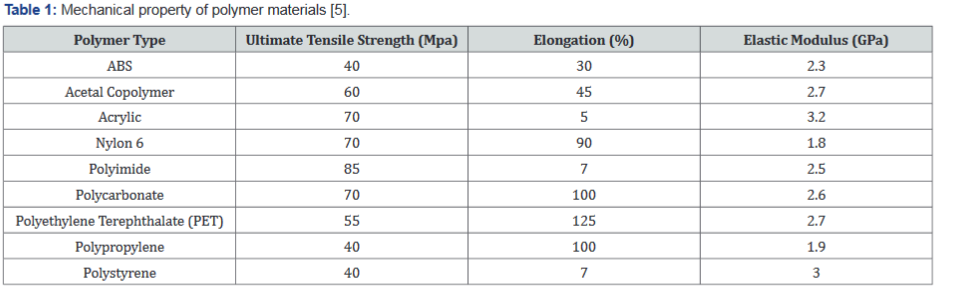

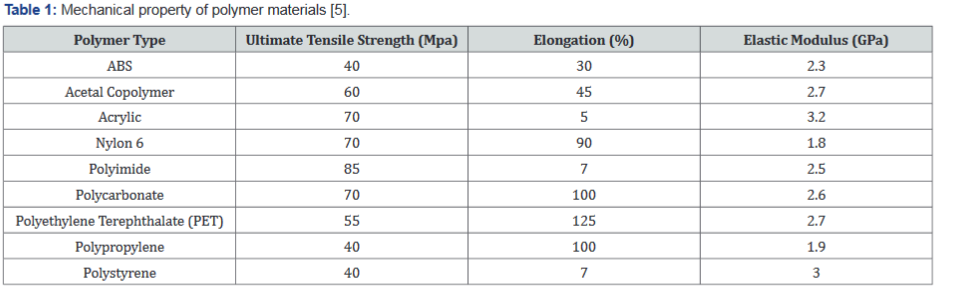

until the break point. Table 1 shows a summary of the mechanical

property of polymer materials [5].

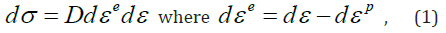

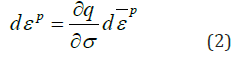

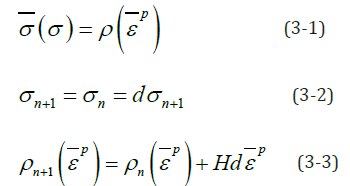

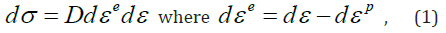

During the plastic deformation, the stress-strain relation is

given as below [6,7]:

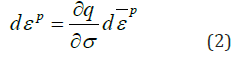

then the increment of the plastic strain is given with the flow

rule,

dσ is the increment of stress, D is the elastic modulus

matrix, dε is the increment of total strain. dε e represents

the increment of elastic strain, dε p is the increment of the

plastic strain. q is the plastic potential function, and p dε is the

equivalent plastic strain. In order to obtain the dε p , below three

conditions should be employed,

σ is equivalent stress, ρ is flow stress model, and H is

the slope of stress-strain curve. Equation (3-1) is the yielding

condition, (3-2) is about the return mapping stress, and (3-3) is

the hardening behavior. Solving the equations from (3-1) to (3-

3) provides the increment of the plastic strain and stress. Then

the strain and stress are used in numerical analysis of the plastic

behavior.

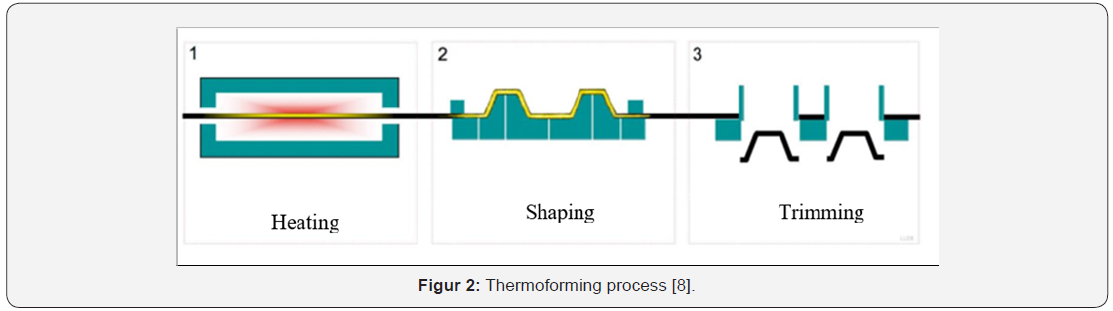

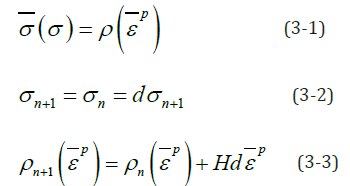

As an application of the plastic behavior, some researchers

have developed forming technologies for polymer materials.

Thermoforming is one of the most popular forming processes

for polymer sheets. As shown in Figure 2 [8], the thermoforming

process consists of three steps; heating, shaping and trimming.

Withthe thermoforming, a polymer sheet is heated to a target

temperature, then formed to a specific shape in a mold. The

formed sheet is trimmed to make a product. The vacuum forming

is very similar to the thermoforming. In the vacuum forming, a

polymer sheet is heated to a target temperature, then stretched

onto a mold, and forced against the mold with a vacuum condition

to reach the target shape.

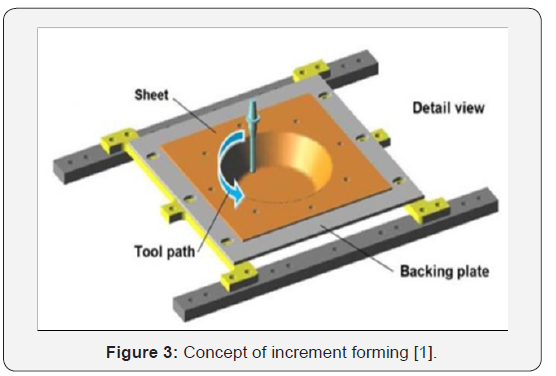

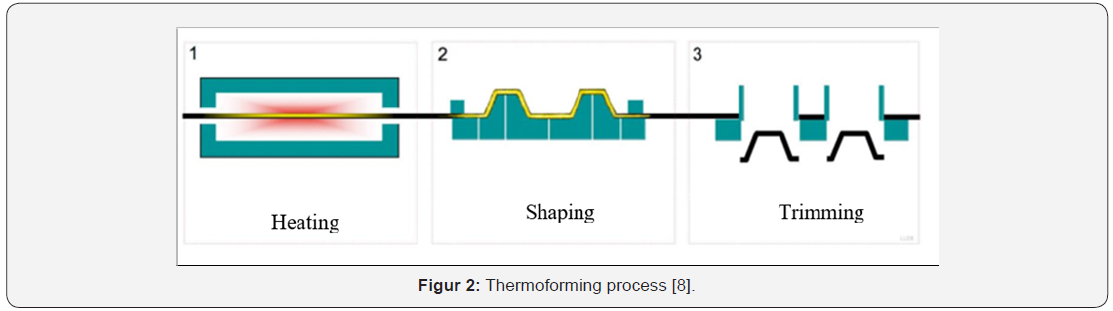

The thermoforming and vacuum forming requires a mold to

form a polymer sheet to the target shape. The investment cost

of the mold is expensive. In addition, a mold cannot be used for another shape. To reduce the cost, some researchers started

studying incremental forming for polymers [9,10]. Figure 3 shows

the concept of the incremental forming. A polymer sheet is locally

deformed by a forming tool which moves on the surface of the

polymer sheet. Since the moving tool is following a defined path in

3-dimensional space, this forming process is flexible to be applied

to arbitrary shapes.

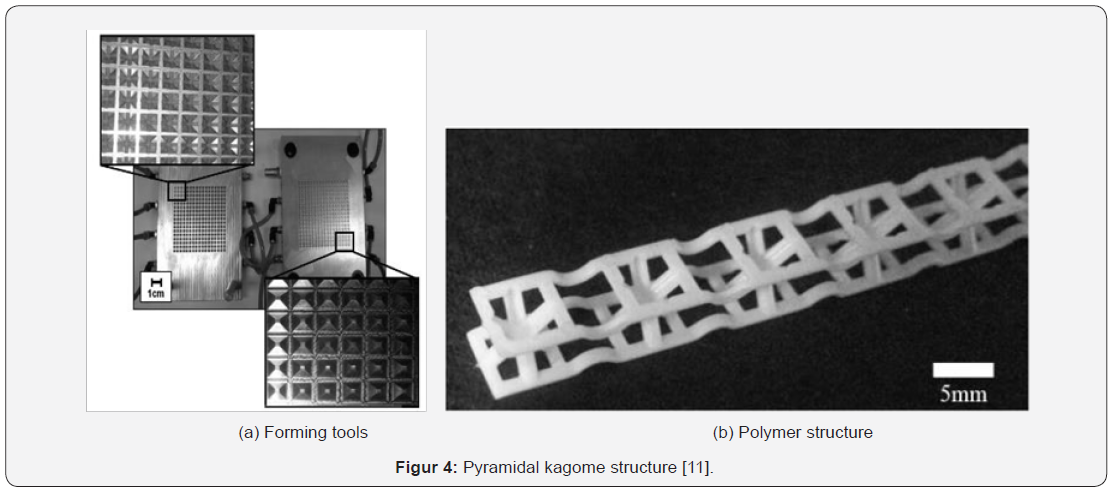

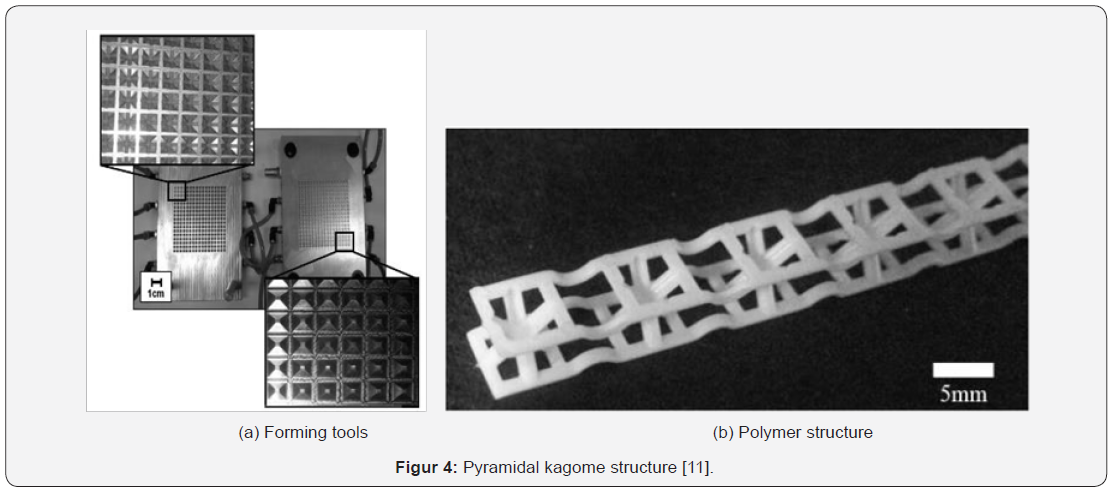

Some researchers have tried to build lightweight structures

with polymers sheets. Figure 4(b) shows a pyramidal kagome

structure made of a polypropylene sheet. Since the polymer

sheet was not able to be deformed to reach the target shape in

room temperature, a heated die set was employed to increase

the formability of the polymer sheet, as shown in Figure 4(a).

This study showed a possibility to make a complex shape by a

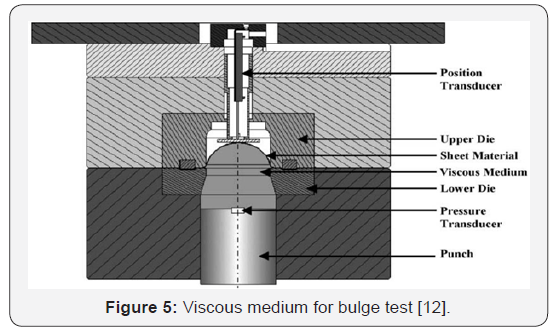

polymer sheet forming process. Polymer sheets can be employed

as a medium material to help metal flow in sheet metal forming

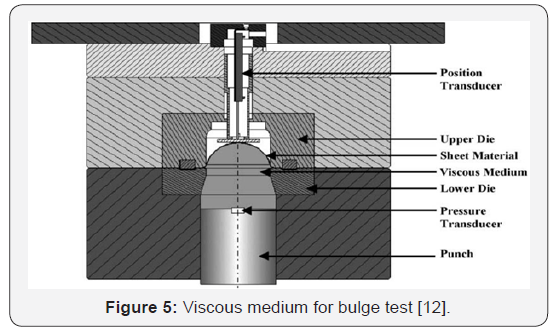

processes. Figure 5 shows a viscous pressure bulge (VPB) test

under biaxial state of stress. Since the viscous medium help the

flow of the sheet metal, the VPB forming process was able to reach

large strain state. As shown in above examples, forming process

of polymer sheets has many chances to be employed in industrial

applications.

Conclusion

This paper briefly reviews the plastic behavior of polymer materials and forming technologies as an application. To make more application of the plastic behavior, forming limit [13] and joining technologies [14] should be accounted. Because of the low cost and great availability, the demand of polymer is getting growing, and both fundamental and practical studies are required [15].

For more

details Academic

Journal of Polymer Science please click on: https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment