Comparative Study on Polyamide 6 Toughness using Multiple Melt-Kneading Techniques-Juniper Publishers

Authored

by Hiroshi Ito

Abstract

In the present work, we tried to toughen polyamide 6

(PA6) by blending a small amount of low molecular-weight polyethylene

(LMWPE). We obtained the PA6/LMWPE blends with different morphologies

using multiple melt-kneading methods such as the uniaxial melt-kneading,

the eight-axial screw melt-kneading, and the high shearing method. As a

result, it was elucidated that the LMWPE was homogeneously and finely

dispersed by using the eight-axial melt-kneading method. On the other

hand, we found that for high shearing method the LMWPE was finely

dispersed to a degree close to the compatible system. The result of the

three-point bending test showed that the PA6 was brittle fractured, but

it changed to ductile fracture when a small amount of LMWPE was blended.

Also, the fracture displacement was extensively improved. The results

of the comparison by the melt-kneading methods revealed that the

toughness of the PA6 was improved even by adding a small amount of LMWPE

(about 2%) when they were blended using the eight-axial screw

melt-kneading machine. The cross-sectional observation in the bending

test showed that voids were produced from the LMWPE. We elucidated that

the production of voids was induced with low stress by adding fragile

LMWPE, resulting in the improvement of the bending toughness. Moreover,

we found that the LMWPE needs to be finely dispersed with an appropriate

particle size in order to exhibit ductile properties.

Keywords:Polymer blend; Higher order structure; Kneading extruder; High-shear rotational processing; High speed impact test Abbrevations: PA6: Polyamide 6; LMWPE: Low Molecular-Weight Polyethylene; TM: Melting Point; TG: Glass Transition Temperature; MFR: Melt Flow Rate; MW: Molecular Weight; HSP: High-Shear Process Kneader; OSE : Octa Screw Kneading Extruder

Introduction

In recent years, due to the rise in environmental

consciousness, weight reduction aimed at reducing the fuel consumption

of automobiles is proceeding. Under these circumstances, the proportion

of using light polymer in automobiles is increasing. However, extremely

high mechanical properties are required for materials loaded in

automobiles. For that reason, the number of cases has been increasing

where a single type of polymer material cannot meet requirements in

automobiles. One of the methods to solve this problem is to use polymer

blend, a mixture of different kinds of polymer materials. Up to now, the

research and development on polymer blend method have been extensively

conducted as a method that exhibits various properties and functions. As

a result, many polymer alloy materials with various characteristics

have been proposed [1,2]. In particular, for polymer materials showing

brittle fracture behavior, it is tried to change them to be ductile by

blending elastomer and gum. However, with these methods, the rigidity of

the polymer materials is generally reduced while increasing ductility

[3,4].

A crystalline polymer, polyamide 6 (PA6), is an

engineering plastic that has extremely high mechanical property because

of the strong molecular-molecular interaction of hydrogen bonds in amide

group. Although PA6 has strong rigidity, it causes brittle fracture

when imposed with a large displacement. Hence it is very important to

change the property of PA6 to be ductile while maintaining its high

rigidity [5]

In the present study, we tried to improve the

toughness of PA6 by blending a small amount of low molecular-weight

polyethylene (LMWPE). The purpose of the work is to clarify the relation

between the inner structure and the mechanical property of the polymer

blends with different morphologies produced by three different kinds of

melt-kneading methods.

Experimental Part

Samples

PA6 (T802, Toyobo Co., Ltd.) was used as the matrix

resin. The glass transition temperature (Tg) and the melting point (Tm)

of PA6 were 50 °C and 218 °C, respectively. The melt flow

rate (MFR) was 26g/10min at 230 °C. As a modifier of PA6,

LMWPE (Hi wax 1105A, Mitsubishi Chemical Co.) was used. The

LMWPE was denatured by maleic anhydride. The Tg was 104

°C, and the average molecular weight (Mw) of the LMWPE was

1,900. The molded film of LMWPE is an extremely brittle and

low-strength material exhibiting a tensile strength of 1.4MPa

and a breaking strain of 0.006 in a tensile test. The blend ratio

of the samples were PA6/LMWPE=98:2 and 95:5 wt%, and the

kneading temperature was 250 °C.

Melt-kneading methods

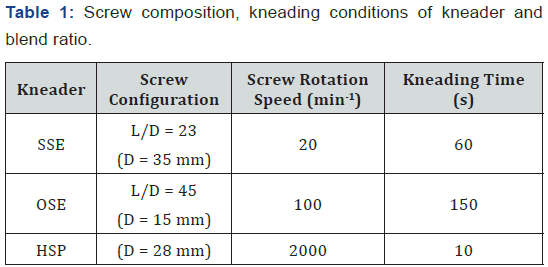

The blend ratio, the details of the melt-kneading machines,

and the kneading conditions for the present samples are shown

in Table 1. The melt-kneading machines used were Single screw

extruder (SSE) (CER40, Hoshi Plastic Co., Ltd.), Octa screw

kneading extruder (OSE) (Technobell Co., Ltd.), and High-shear

process kneader (HSP) (Niigata Machine Techno CO., Ltd). The

OSE was used for low-shear kneading. Therefore, it is expected

that we obtain the products with relatively large domain diameter.

The OSE is a machine where all eight screws engage and rotate in

the same direction. Since the resin stays among eight screws in

the OSE, the long-time kneading is possible compared with the

SSE. The HSP is a batch-type kneading machine and has a special

screw with a small hole in the center (return hole). Hence, it is

possible to knead a certain amount of resin at arbitrary rotation

speed and time [6-9].

The samples after kneading were pelletized, and then molded

to three-point bending test pieces and flat plate test pieces using

the injection molding machine.

SEM observation

The samples after kneading were frozen and fractured

in liquid nitrogen, and the fracture surface was observed by a

scanning electron microscopy (SEM).

Mechanical properties and observation of plastic deformation region

Three-point bending tests were conducted for specimens

with notches. The Poisson contraction at the tip of the notch is

suppressed due to the constraint of the distortion. Hence the

pure uniaxial stretching test becomes possible. This test method

is known to be effective for the evaluation of toughness (ductile

or brittle) for polymer blend materials [10]. As additional

experiments, the bending test was stopped at the displacement

just before the fracture or at the maximum displacement (10mm),

and the sample was fixed by embedding with epoxy resin.

The plane of the sample perpendicular to the tip of the notch

was then scraped to 20μm thick thin film using a microtome.

The void-producing region in the plane was observed with a

polarization microscope.

Impact resistance evaluation

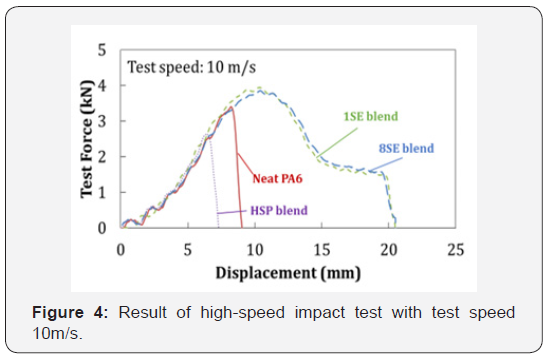

For evaluating the impact strength at the time of rapid deformation,

a high-speed impact test (punching) was conducted. The

sample molded to a plane shape was punched by a test rod of

10mm diameter, and the stress was measured. The speed of the

impact test was 10m・s-1.

Results and Discussion

Morphology observation

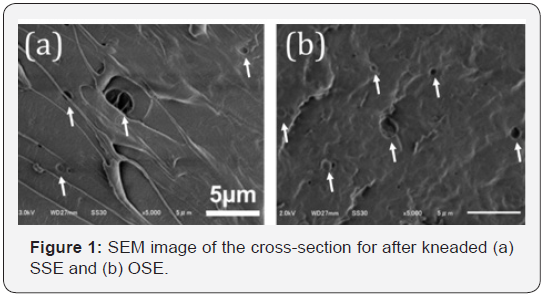

Figure 1 shows the cross-sectional SEM images for PA6/

LMWPE kneaded by SSE (a) and OSE (b). For the SSE-kneaded

sample, LMWPE aggregates with a maximum particle size of 3μm

were observed. The size of the aggregates was not homogeneous.

For the OSE-kneaded sample, we confirmed the LMWPE

aggregates with a particle size from 1μm to 2μm. The size of the

aggregates was relatively homogeneous compared with that of

the SSE-kneaded sample. For the HSP-kneaded sample, LMWPE

aggregates were not observed. The reason would be that the

LMWPE was extremely finely dispersed in this case.

Three point bending test and observation of plastic deformation region

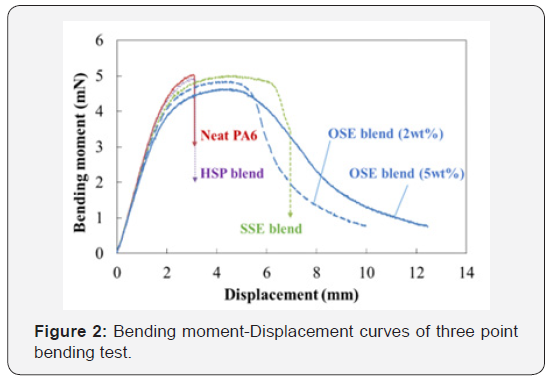

Figure 2 displays the results of the three-point bending test

for pure PA6 and PA6/LMWPE blends produced by respective

kneading methods. Only OSE kneaded-samples were prepared

with LMWPE addition amount of 2 and 5wt%. For the pure

PA6, SSE-kneaded sample, and HPS-kneaded sample, they were

finally brittle fractured. In particular, for the HSP-kneaded

blend, the fracture behavior was same as that of the pure PA6,

thus the effect of the LMWPE blending could not be confirmed.

On the other hand, the OSE-kneaded sample showed plastic

deformation, and it was not fractured even at the maximum

displacement (10mm) resulting in the general yield. The OSE

kneaded sample (LMWPE: 5wt%) showed better breaking

elongation than the system in which LMWPE(added 2wt%),

but the maximum bending strength greatly decreased. This

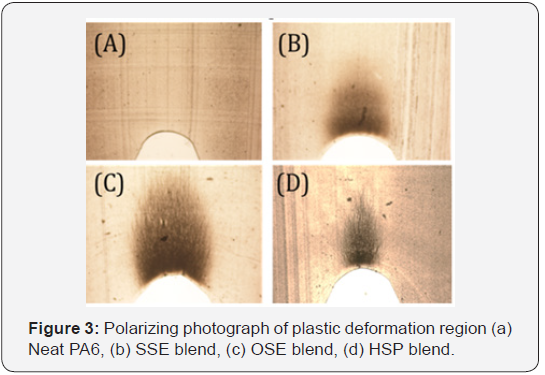

result seems to be due to excessive addition of brittle LMWPE. Figure 3 presents the polarization microscope image of the

plastic deformation region produced at the tip of the notch in

the bending test. For the pure PA6 (a), voids were not produced

even at 3.2mm deformation, just before the fracture. While

for SSE-kneaded blend (b), the plastic deformation region

originating from the voids formation was confirmed for the

sample just before the fracture (displacement: 6mm). In this

case, the blending of LMWPE induced the void formation, and

the Poisson contraction among the voids became possible, which

led to the ductile behavior of the sample compared with the pure

PA6. However, the stress was locally concentrated because of the

inhomogeneous size of the dispersed LMWPE. Therefore, it is

considered that the sample finally resulted in the brittle fracture.

For the OSE-kneaded sample (c), we confirmed the plastic

deformation regions that are wider than those for the SSEkneaded

one at the same displacement (6mm). Compared

with the SSE-kneaded sample, the OSE-kneaded one exhibited

morphology where the size of the LMWPE aggregates was small

and homogeneous. Therefore, the distance among the LMWPE

aggregates was homogeneous, so the sample was homogeneously

deformed due to the dispersion of the stress. As a result, it is

considered that the sample resulted in the general yield without

the brittle fracture even at the maximum displacement.

For the HSP-kneaded sample (d), we observed a fine plastic

deformation region at the displacement (3.2mm), just before

the fracture. By the high shearing kneading, the LMWPE showed

the dispersion condition that is close to the homogeneous

compatibility system. As a result, voids expansion did not proceed

because the size of the produced voids was extremely small.

Thus, the stress constraint was not relaxed because the Poisson

contraction was not sufficient. This would be the reason that

the HSP-kneaded sample finally resulted in the brittle fracture.

Based on the above results, we controlled fragile LMWPE to

exhibit fine (about 1μm size) and homogeneous higher-order

structure. By doing so, the void formation was induced, and the

stress was relaxed. As a result, we succeeded in improving the

toughness of PA6. On the other hand, the HSP-knead blended

sample with excessively finely dispersed LMWPE did not have a

higher-order structure. We consider that the blending of LMWPE

did not lead to improve the toughness of PA6 in this case because

the stress relaxation function did not work.

High-speed impact test

Figure 4 shows the load-displacement curve in the highspeed

impact test at 10m.s-1. At this speed, both the PA6 and

the HSP-kneaded samples were brittle fractured. The reason

is that in both samples the cracks were developed because the

stress was not relaxed in the deformation at the high speed.

On the other hand, the SSE- and OSE-kneaded samples showed

ductile fracture. For these samples, the LMWPE that is easy to be

fractured existed as domains with 1-3μm diameter. The stress

relaxation effect expressed even at high speed of 10m・s-1 because

the LMWPE became the origin of voids. Based on these results,

we succeeded in leading the SSE- and OSE-kneaded blends to

the ductile fracture. On the other hand, the effect of the stress

relaxation effect in the HSP-kneaded sample that has extremely

fine dispersed structure of the LMWPE was not sufficient. We

consider this is the reason why the HSP-kneaded sample led to

the brittle fracture.

Conclusion

In the present work, we tried to toughen PA6 by

blending a

small amount of LMWPE. We obtained the PA6/LMWPE blends

with different morphologies using multiple melt-kneading

methods such as the uniaxial melt-kneading, the eight-axial screw

melt-kneading, and the high shearing method. As a result, it was

possible to lead to ductile fracture while maintaining rigidity by

adding a small amount of LMWPE to PA6. Kneading by OSE was

effective for finely dispersing LMWPE and equalizing dispersed

particle size, and the properties of the blended material were

also the most stable. This result seems to be because Poisson

contraction was possible even at high speed deformation, and

PA6 could lead to ductile fracture, since LMWPE which breaks

easily is the starting point of void formation. However, when

LMWPE was dispersed in a region close to the nano order and

homogeneous system, the effect of adding LMWPE did not

appear. It has been found that it was important to form a higher

order structure having an island phase size larger than a certain

level for toughening by polymer blending.

Acknowledgement

This research was partially funded by Impulsing Paradigm

Change Through disruptive Technologies (ImPACT) Program of

Council for Science, Technology and Innovation (Cabinet Office,

Government of Japan).

For more

details Journal of Polymer Science please

click on: https://juniperpublishers.com/ajop/index.php

To read more…FullText in Juniper Publishers click on https://juniperpublishers.com/ajop/AJOP.MS.ID.555563.php

Comments

Post a Comment