A Comparative Study of Multiwalled Carbon Nanotube Based Polystyrene and Toughened Polycarbonate Nanocomposites-Juniper Publishers

Authored

by Nisha Bagotia

Abstract

The main objective of this article is to describe the

effect of different length (aspect ratio) of carbon nanotubes (CNTs) on

the electrical conductivity and electromagnetic shielding effectiveness

of polystyrene/l-MWCNT and toughened polycarbonate/s-MWCNT composites.

Long and short MWCNTs having aspect ratio of ~666 - 1333 and ~157

respectively were used for melt-mixed with polystyrene and toughened

polycarbonate in a micro compounder. The uniform dispersion of MWCNT in

matrix was confirmed by scanning electron microscopy. The realization

shielding effectiveness value of -21dB respectively for PS/l-MWCNT

composites: and -27dB for TPC/s-MWCNT composites at 10phr loading of

MWCNTs, which show their potential use in making of mechanically strong

and light weight EMI shield used for commercial application.

Keywords: Polycarbonate; Polystyrene; Multiwalled carbon nanotube; Electrical properties; EMI shielding effectiveness Abbrevations: Carbon Nanotubes; EC: Electrical Conductivity; EMI: Electromagnetic Interference; l-MWCNTs: Long Length Multiwalled Carbon Nanotubes; PC: Polycarbonate; PS: Polystyrene; PTT: Poly(trimethylene terephthalate); SE: Shielding Effectiveness; SEM: Scanning Electron Microscope; s-MWCNTs: Small Length multiwalled carbon nanotubes; s-MWCNTs: Small Multiwalled Carbon Nanotubes; SWCNTs: Single Walled Carbon Nanotubes; TEM: Transmission Electron Microscope; TPC: Toughened Polycarbonate; VNA: Vector Network Analyzer

Introduction

The broad developments of electronic systems and

telecommunications has led to a novel type of pollution i.e.

electromagnetic interference (EMI). EMI has appeared as a major problem,

which not only affecting the proper working of electronic devices but

as well as causing harmful effects to the health of human beings [1,2].

Generally, mobile phone, radar, radio transceivers, microwave oven, and

various electronic devices are the main causes of EMI [3,4]. The long

time exposure of EM waves have also been recognized as strong

cancer-causing agent [5]. Therefore, appropriate shield is required to

reduce the effect of EM waves. Generally, electrically conductive or

magnetic filler are used as a EMI shielding material, because these

materials have capability to interact with coupled electric and magnetic

fields of the incident EM waves [6,7]. Metals and metal loaded

composites have been widely used as EMI shielding materials, but these

materials have disadvantages such as high density, corrosion prone,

inconvenient processing etc. which limits their practical applicability.

As compare to the metals, carbon nanomaterials have appeared as

promising alternative conductive filler for production of EMI shield

[6,8,9].

Nowadays, the use of carbon nanotubes (CNTs), having

ultra-high modulus and strength, good thermal and electrical properties,

as filler in polymer nanocomposites prepare material with lower filler

loadings having improved electrical and EMI shielding properties

[10-15]. As reported in literature, mechanical strength, electrical

conductivity or thermal properties and EMI shielding effectiveness of

the polymer nanocomposites are affected by different factors such as the

aspect ratio, dispersion, processing methods, treatment methods, and

loading of CNTs [16]. Li et al. [15] studied the conductivity and EMI SE

of epoxy/SWCNT nanocomposites filled with SWCNTs having different

aspect ratios. The maximum EMI shielding effectiveness has been reported

for epoxy/SWCNT composites having 15wt% SWCNTs-long (SE ∼49dB and

15-20dB obtained at 10MHz and in the 500MHz to 1.5GHz range

respectively). In another study, Gupta et al. [17] reported EMI

shielding properties (in Ku-band) of poly (trimethylene terephthalate)

(PTT)/MWCNT nanocomposites. Electrical percolation of composites has

been reported at 1wt% loading of MWCNT and SE of 36-42dB reported at

10wt% loading of MWCNT. Bai et al. [18] described the effect of nanotube

aspect ratio on the electrical properties and mechanical strength of

the epoxy/MWCNT nanocomposites using three different length of

MWCNTs (~1,10,50μm). It has been found that the short length

MWCNTs (10μm) report good mechanical properties while

long length MWCNTs (50μm) improved electrical properties of

nanocomposites. Singh et al. [19] investigated the effect of CNTs

having different aspect ratio on the electrical, mechanical and

EMI shielding properties of epoxy/CNTs nanocomposites at

low loading of CNT (0.5wt%). It has been observed that high

aspect ratio CNTs filled nanocomposites show higher electrical

(percolation threshold at 0.02wt% loading of l-MWCNT),

mechanical (125MPa at 0.3wt% loading of l-MWCNT) and EMI

shielding properties (highest SE ~16dB) in comparison to those

filled with lower aspect ratio MWCNTs (percolation threshold at

0.11wt%, flexural strength -113MPa at 0.3wt% and maximum

shielding of ~11dB). Huang et al. [20] investigated the effect

of heat treatment and CNTs with different aspect ratio on the

EMI shielding effectiveness of epoxy/SWCNT nanocomposites

(up to 15wt% SWCNTs). They reported that long SWCNTs based

nanocomposites give high EMI SE (SE ~3 to 28dB) as compared

to short annealed SWCNTs (SE ~21-23dB) and unannealed

short SWCNTs (SE ~17-18dB). Al-Guo et al. [21] studied the

effects of MWCNTs with high aspect ratio (313 and 474) on the

electrical, mechanical, and thermal properties of PC/MWCNT

nanocomposites. Above mentioned literature showed that most

of studies either show EMI shielding effectiveness or mechanical

properties of different types of MWCNTs based nanocomposites

under higher loading of CNTs; or with both mechanical and

EMI properties under lower loading of CNTs. Therefore, a

comparative study of the preparation of higher loaded MWCNT

nanocomposites and describing the effect of aspect ratio of

MWCNTs on the mechanical, electrical and EMI shielding

properties, of polymer nanocomposites is necessary.

The main objective of this paper to describe the effect of

aspect ratio of MWCNTs on the electrical and EMI shielding

properties of MWCNT based polystyrene (PS) and toughened

polycarbonate (TPC) composites containing up to 10phr

MWCNTs. The nanocomposites have been prepared by melt

compounding of PS and TPC with MWCNTs in a twin screw

micro-compounder. Two types of MWCNTs viz. long (l-MWCNT)

having diameter ~7.5nm & length ~5-10μm (aspect ratio ~666-

1333) and short (s-MWCNTs) having diameter 9.5nm & length

~1.5μm (aspect ratio ~157) were used for the fabrication

of nanocomposites. The dispersion of MWCNTs in matrix is

investigated by scanning electron microscopy. The EMI shielding

of nanocomposites was measured in X-band (frequency range of

8.2-12.4GHz). The morphology, electrical conductivity and EMI

shielding effectiveness of composites have been interrelated

with distribution density and aspect ratio of CNTs, under both

lower and higher loading.

Materials and Methods

Materials

Polystyrene (SC206) was purchased from Supreme

Petrochem limited. Polycarbonate (PC) Lexan 143, procured

from Sabic Innovative Plastic. Ethylene methyl acrylate (EMA)

copolymer (Elvaloy® AC 1330 from DuPont) having 70% by

weight ethylene and 30% by weight methyl acrylate are used in

this investigation for toughening of PC [22,23]. Here, 5wt% EMA

containing PC (TPC) is used for study. The long length MWCNTs

(l-MWCNTs) were produced by CVD method using pongamia oil

as a carbon source and ferrocene as catalyst and preparation

process is mentioned elsewhere [24]. The diameter of l-MWCNT was in the range of 50-200nm and length is in the range 5-10μm.

The short length MWCNTs (s-MWCNTs), grade NC7000 with

90% carbon purity (length ~1.5μm and diameter ~9.5nm) were

obtained from Nanocyl, Belgium.

Methods

Fabrication of PS/MWCNT and TPC/MWCNT nanocomposites

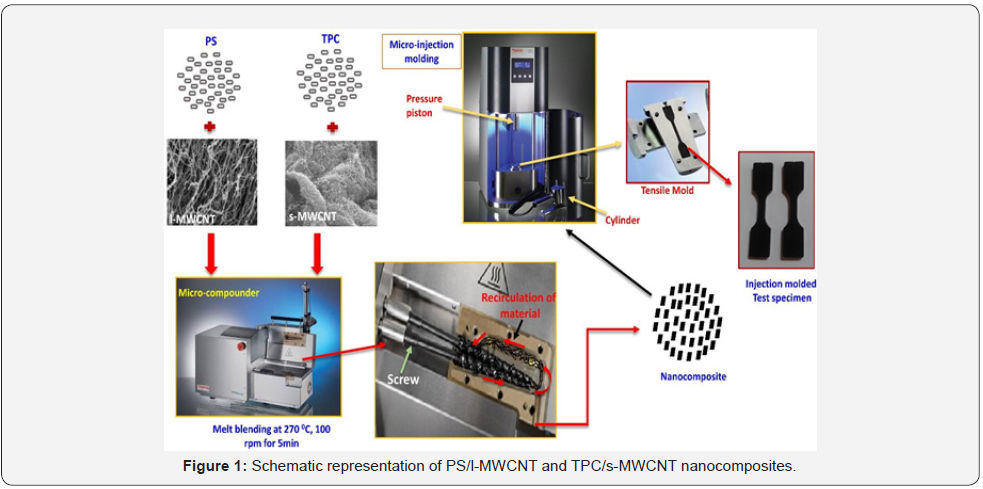

The melt blending approach for fabrication of PS/l-MWCNT

and TPC/s-MWCNT composites was used in this study. Drying

of PS, TPC and MWCNTs was performed before melt blending

for 24 h at 70 °C in oven. Melt blending of nanocomposites was

carried out by using micro-compounder at 270 °C processing

temperature, screw speed 100rpm and mixing time 5min. The

continuous strands obtained were pelletized and then followed

by drying in the oven for injection molding. The micro-injection

molding machine was used for the preparation of test specimen

of PS/l-MWCNT and TPC/s-MWCNT nanocomposites. Cylinder

temperature, mold temperature and pressure for injection

molding were 250 °C, 100 °C and 640bar respectively. The

formulation and sample designation of the PS/l-MWCNT and

TPC/s-MWCNT composites are given in Table 1. The schematic

representation of the nanocomposites fabrication is illustrated

in Figure 1.

*where PS-polystyrene, TPC- toughened polycarbonate,

l-CNT- long multiwalled carbon nanotube, s-CNT- small

multiwalled carbon nanotube, Numerical value- MWCNT

content.

Characterization of PS/MWCNT and TPC/MWCNT

nanocomposites

PS and TPC nanocomposites were characterized by

morphological, electrical, EMI shielding thermal and

spectroscopy study. Surface morphology of these nanocomposites

were inspected using scanning electron microscope (SEM Zeiss

EVO 50 at magnification of 30,000) and transmission electron

microscope (TEM Zeiss 200kV). The cryofractured surface

of composites were used for SEM imaging. The electrical

conductivity (EC) of the nanocomposites at room temperature

was measured by two point contact method using a Keithley 224

programmable current source. Electromagnetic interference

shielding of composites were recorded on Agilent E8362B

Vector Network Analyzer (VNA) in 8.2-12.4GHz frequency range

(X-band).

Results and Discussion

Morphological characterization

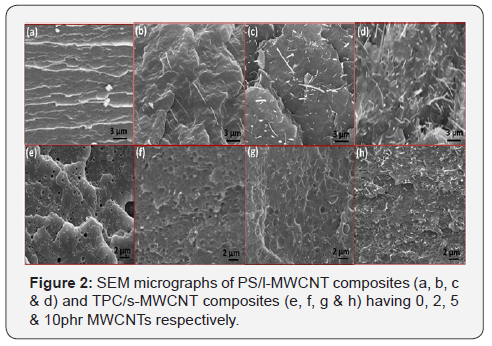

SEM images of l-MWCNTs and s-MWCNT based PS and TPU

nanocomposites are presented in Figure 2a - 2h respectively.

MWCNTs are homogenously dispersed in the matrix, even

at 10phr loading as observed from the images. Thus, melt

blending using micro-compounder is an effective technique

for homogenous dispersion of MWCNTs in matrix. From SEM

images, it is also observed that, at any specific MWCNT loading,

the distribution density of s-MWCNT in TPC matrix is higher

compared to l-MWCNTs in PS matrix. These s-MWCNTs have

more surface area in comparison to l-MWCNTs for interfacial

interactions with TPC matrix, which are necessary for good

mechanical strength and EMI shielding. On other side, l-MWCNTs

with higher aspect ratio are expected to provide good stress

transfer properties, low percolation threshold and long-range charge transport in PS matrix. Therefore, depending on the

aspect ratio of MWCNTs, their distribution and loading inside

matrix, significant mechanical, electrical and EMI shielding

properties are expected.

Electrical conductivity (EC)

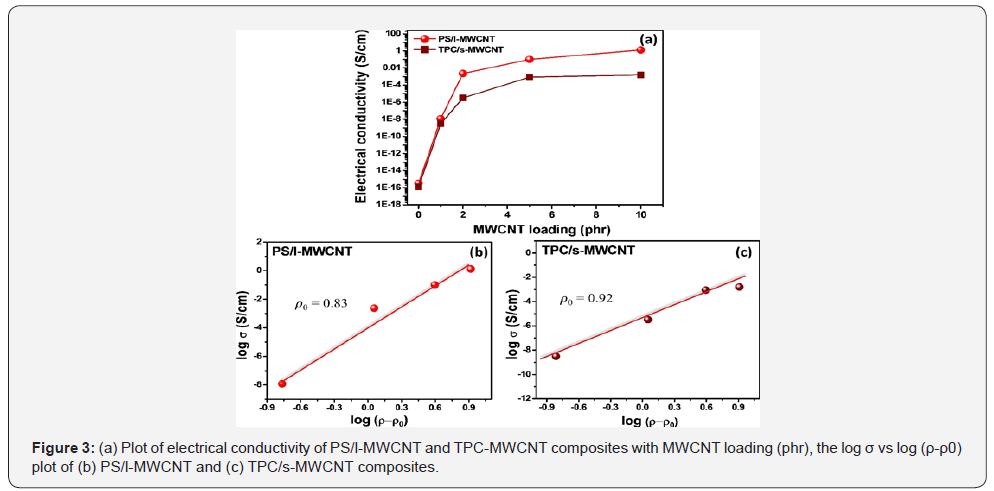

The EC of PS/l-MWCNT and TPC/s-MWCNT nanocomposites

with respect to MWCNT loading is presented in Figure 3. The

EC of nanocomposites based on l- and s-MWCNT increased with

increasing MWCNT loading and shows a drastic increase (~

eight and seven orders of magnitude respectively) below 1phr

MWCNT content, which show the formation of 3D conducting

networks. Such a low percolation threshold value is due to

the uniform dispersion of MWCNTs in matrix. It is reported in

literature that percolation threshold is basically dependent on

the different factors like the aspect ratio, intrinsic conductivity

and dispersion of the conductive nanofiller [25-27]. Therefore,

the exact value of threshold of l- and s-MWCNTs, has been

projected by plotting the EC as a function of the MWCNT loading

and performing data fitting using the scaling law [28-

where σ , σ 0 , ρ , ρ 0 and t represents the EC of the

nanocomposites the intrinsic conductivity of the nanofiller,

volume fraction of nanofiller, the volume fraction at the

percolation threshold and the critical exponent related to the

system dimensionality respectively.

The linear regression data fitting (Figure 4 b & 4c) gives ρ0 =

0.83phr & β = 1.54 for PS/l-MWCNT and ρ0 = 1.07 wt.% & β = 1.09 for TPC/s-MWCNT nanocomposites.

Considering the good dispersion of both l- and s- MWCNTs, the low

percolation threshold for l-MWCNTs can be attributed to its high

aspect ratio as compared to s-MWCNTs. It can also be seen that

at any loading level, EC of PS/l-MWCNT nanocomposite is higher

than respective TPC/s-MWCNT nanocomposite. This can again

be attributed to the higher aspect ratio of l-MCWNTs responsible

for long range charge transport in nanocomposites. As the EMI

shielding is also related to the EC, the observed EC trend of

nanocomposites recommend that, at comparative loading, EMI

shielding effectiveness of PS/l-MWCNT nanocomposites should

be higher than TPC/s-MWCNT nanocomposites.

Electromagnetic interference shielding (EMI SE) of nanocomposites

The EMI SE is the capacity of a material to attenuate incident

electromagnetic waves. The EMI shielding is a direct result of

the absorption of the wave as it passes through the shield’s

thickness, the reflection of the wave from the front face of

the shield and multiple reflections of the waves at various

interfaces. The presence of charge carriers in material helps

in electromagnetic wave reflection via reflection mechanism

electromagnetic wave penetrate through the material and

get attenuated via the absorption. Absorption loss is more

important for the magnetic field of electromagnetic wave than

the electric field. Therefore, the electric field of electromagnetic

wave is mostly reflected at the interface. The total SE of a

material can be expressed in logarithmic power ratio as [32]

Where SEA, SER and SEM are the SE due to absorption,

reflection and multiple reflections respectively and Pi is the

power of incident wave and Pt is transmitted EM wave.

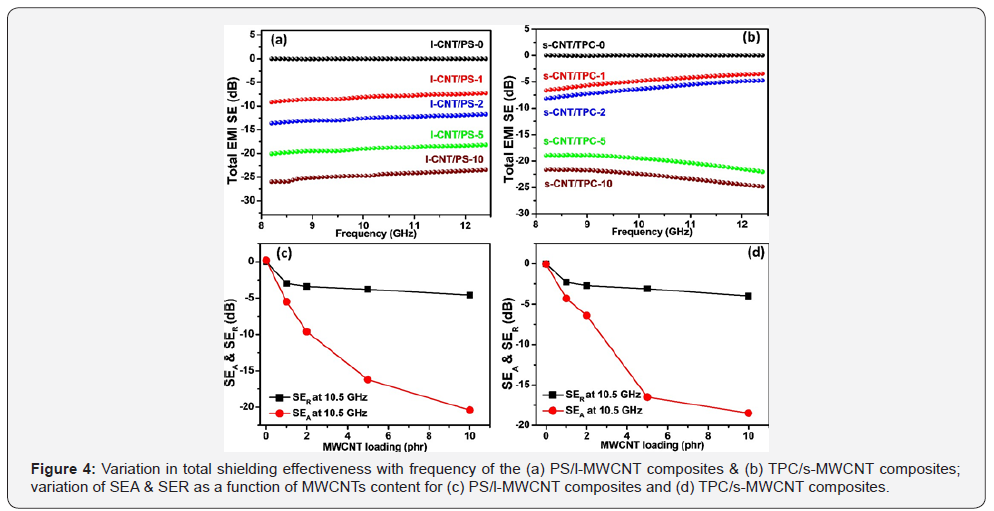

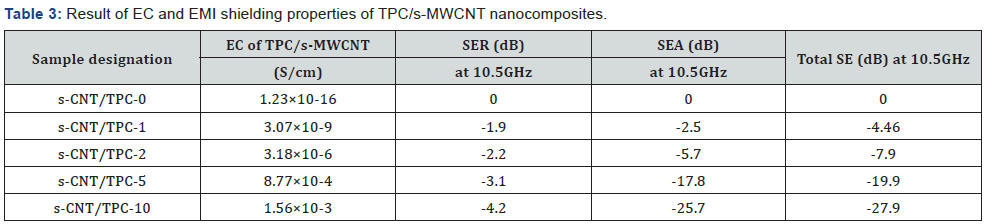

Figure 4a & 4b shows the total SE of PS/l-MWCNT and TPC/

s-MWCNT nanocomposites respectively. It can be observed that

neat matrix (PS and TPC) sample gives negligible attenuation.

However, incorporation of MWCNTs causes enhancement in

SE for both PS/l-MWCNT and TPC/s-MWCNT nanocomposites

obtaining SE value of - 21dB and - 27dB at 10phr loading

of MWCNT, respectively as given in Table 2 & 3. This can be

ascribed to the formation of conducting networks throughout

the insulating PS and TPC matrix. The EMI shielding results also

shown that at lower loading (up to 2phr MWCNT loading), SE of

PS/l-MWCNT nanocomposites is higher compared to s-MWCNT

based nanocomposites, but at higher loadings, s-MWCNT based

composites show higher EMI SE. Accordingly, PS/l-MWCNT-1

and TPC/s-MWCNT-2 show approximate similar shielding

effectiveness (~-7.8db). These results indicate the effectiveness

of l-MWCNTs at lower loading and s-MWCNTs at higher loading.

The total SE have two components i.e. reflection and

absorption (SER and SEA). Both SER and SEA increases with

MWCNT loading can be observed from Figure 4c & 4d. The SEA

increases at much faster rate as compare to SER in both the cases

with increase in MWCNT loading. A brief investigation shows

that at any given loading l-MWCNTs filled nanocomposites

show superior SER value as compare to s-MWCNTs filled

nanocomposites. However, absorption trend shown that below

5phr loading of CNT, PS/l-MWCNT nanocomposites show

superior SEA values whereas at higher loadings, SEA of TPC/s MWCNT nanocomposites dominate. This can be attributed to the

fact that at lower loadings, the interfacial polarization effects are

not too dominant, and conductivity shows the important role.

Consequently, the TPC/s-MWCNT nanocomposites with a lower

conductivity compare to PS/l-MWCNT nanocomposites show

lesser attenuation. However, at higher loadings, better input

impedance matching in case of TPC/s-MWCNT nanocomposites

allows more incident waves to enter inside the shield that can be

effectively dominated by absorption mechanism.

Conclusion

PS/MWCNT and TPC/MWCNT nanocomposites having up to

10phr loading of different aspect ratio MWCNTs (i.e. long and

short MWCNTs respectively) have been prepared by melt mixing

method. These nanocomposites show improved electrical

conductivity and low electrical percolation threshold (i.e. 0.83

and 0.91phr for PS/l-MWCNT and TPC/s-MWCNT composites

respectively) which is the sign of uniform dispersion of

MWCNTs in the matrix. Further, the good electrical conductivity,

processing induced morphology and difference in aspect ratio

are responsible for observed maximum attenuation of -21dB and

-27dB for PS/l- MWCNT and TPC/s-MWCNT nanocomposites

respectively. It was also detected that PS/l-MWCNT

nanocomposites show better SE at lower loading (up to 5phr)

whereas TPC/s-MWCNT nanocomposites give better SE at higher

loading. The aspect ratio of MWCNTs have been interconnected

with the observed trends of electrical conductivity and EMI SE.

These nanocomposites with good electrical conductivity along

with high EMI shielding are considered as potential aspirant for

making commercially feasible EMI shields.

For more

details Academic

Journal of Polymer Science please click on: https://juniperpublishers.com/ajop/index.php

To read more…Full Text in Juniper Publishers click on https://juniperpublishers.com/ajop/AJOP.MS.ID.555561.php

Comments

Post a Comment