Ballistic Studies on Fox-7 Based Triple Base Propellant for High Calibre Gun-Juniper Publishers

JUNIPER PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

In the present work, triple base propellant (TBP)

containing mainly energetic nitrate polymer nitrocellulose and

nitroglycerine, picrite, 1,1-diamino-2,2-dinitroethene (FOX-7) along

with ingredients such as stabiliser and plasticizer has been processed

by solvent method. Picrite has been replaced in increments with FOX-7

from the propellant composition. Acetone: ethanol used as solvent to

gelatinise/plasticize NC during processing. Dimensions of the propellant

was determined by physical measurement and propellant grains were

subjected to mechanical properties (compressive strength (CS), %

compression) determination, sensitivity tests and closed vessel (CV)

firing. Incorporation of FOX-7 led to remarkable increase in CS at

sub-zero temperatures (-20°C) and reduced at higher temperatures (+55°C)

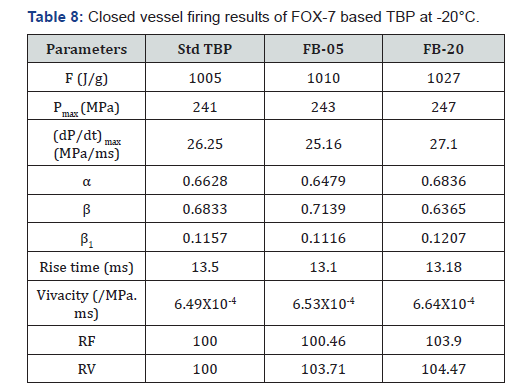

for 20 % FOX-7 in TBP composition. CV test of the propellant was

carried out at 0.2g/cc loading density in 700cc closed vessel at +21,

-20 & +55°C to evaluate ballistic parameters such as Pmax, force

constant, (dP/dt) max, pressure index (α), burning rate coefficient (β),

rise time, relative force (RF) and relative vivacity (RV). The trends

observed during this work bring out the potential of FOX-7 to impart

temperature independent characteristics in the TBP used for high calibre

gun.

Keywords: FOX-7; Pressure index; Force constant; Burning rate; Chamber pressure

Introduction

FOX-7 or 1,1-diamino-2,2-dinitroethene (DADNE) as

reported by Lochert [1] is a low vulnerable energetic compound. It was

first synthesized in 1990s by the FOA Defence Research Establishment

(Sweden). However, its application in propellant has received attention

during last decade. The performance of FOX-7 is comparable to

cyclotrimethylene trinitramine (RDX) whereas its impact and friction

sensitivities are much less than that of RDX and other nitramines.

Calculated detonation velocity of FOX-7 based high

energy compositions has been of the order 9090m/s compared

to 8800m/s for RDX based compositions [1-3]. FOX-7 has a potential

for application in high performance IM-compliant explosive

formulations. Most of the research establishments working in the

area of high energy materials (HEMs) like Aeronautical and Maritime

Research Laboratory (AMRL) have focused on the synthesis,

hazards characterisation and performance evaluation of FOX-7.

Dorsett [4] has mentioned in the report that 1,1-diamino-2,2-dinitroethene

i.e. FOX-7 is like the insensitive chemical compound triamino

trinitro benzene (TATB), a benzene ring compound having

three amino and three nitro groups. FOX-7 has a two-carbon backbone

in place of a benzene ring, but the amino and nitro groups

have similar effects in both cases according to published reports

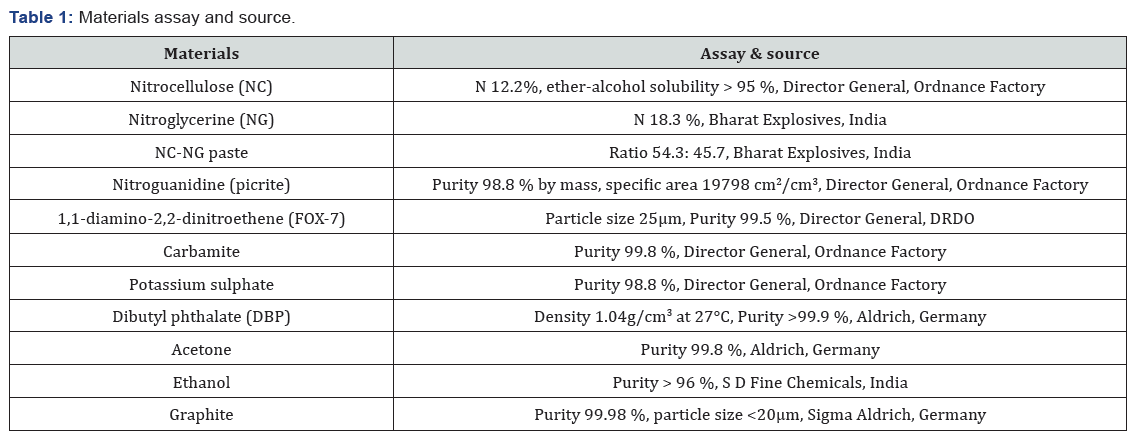

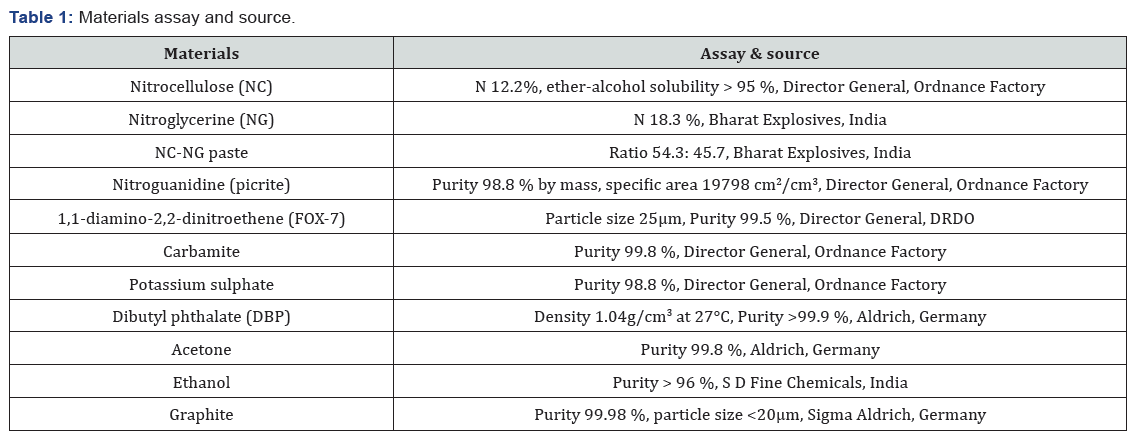

on sensitivity and chemical decay processes of FOX-7 [5] Table 1.

It is mainly produced by Eurenco Bofors AB & Sweden [1,6,7].

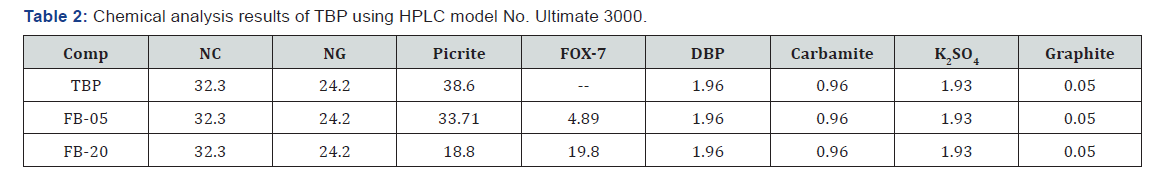

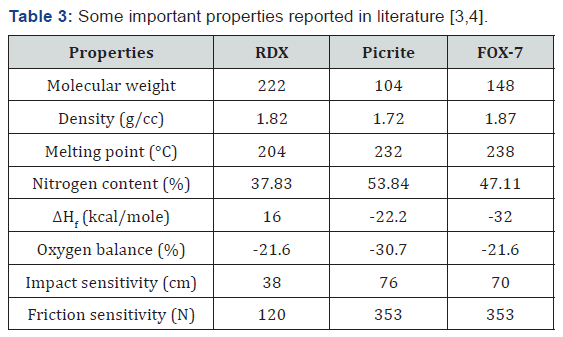

Some of the characteristics of FOX-7 vis-a-vis RDX and picrite are

given in Table 2. Various tests such as slow cook off, fast cook off,

bullet impact test have been conducted along with Composition

B to establish the insensitive nature of FOX-7 based propellants.

Most of the reported literature pertains to FOX-7 based plastic

bonded explosives. FOX-7 based compositions have undergone

deflagration (type V reaction) whereas, Composition B has given

detonation response (type I reaction). Burn rate (mm/s) was

found to increase with pressure (MPa) and force constant (J/g)

was found to increase with temperature.

Thus, FOX-7 enhanced the safety of propellant without much

compromise on propellant energy. Mishra et al [3] have also

studied lower vulnerability of FOX-7 based, non-aluminized and

aluminized, melt cast explosive with marginal decrease in performance

compared to RDX based compositions. S Karlsson [8] has

reported height of 50% explosion (H50) 63 - 79cm in Drop hammer

tests and no reaction in the friction test (>340 N). A castable composition

of FOX-7 and poly-glycidyl nitrate (Poly-GLYN) has also

been studied by these researchers. Limited safety tests indicated

that the compositions with FOX-7 were less sensitive to friction, it

had excellent thermal stability at 65°C and slow cook-off stimuli.

It did not detonate at a diameter of 25 mm and upon slow heating

(3.3°C/hour) it ignites at 220°C and burns without damage to the

container or the surroundings. Limited work has been reported

in literature on FOX-7 based propellant. Wuxi Xie et al. [9] studied

the performance of Nitrate Ester Plasticized Polyether (NEPE)

rocket propellants containing FOX-7 as replacement of Cyclotetramethylene

tetranitramine (HMX). They observed decrease in

combustion temperature by about 100K and increase in burning

rate as well as pressure exponents. Moreover, tensile strength of

the propellants was increased, whereas maximum elongation decreased

by about 40%. The initiation probability under pressure

decreased by 12% along with decrease in friction sensitivity of the

propellant suggesting improved insensitivity characteristics. Bogdan

Florczak [10] observed that, the propellant containing FOX-7

has a comparable deflagration temperature and gaseous reaction

products volume as the composite propellant containing the

same amount of HMX. Linear burn rate of propellant formulation

containing FOX-7 is nearly 17% less than that of the propellant

formulation containing HMX. Hendrik Lips et al. [11] has studied

FOX-7 / Ammonium perchlorate (AP) / Glycidyl Azide Polymer

(GAP) based rocket propellants for a shoulder launched projectile.

It is found that formulations containing FOX-7, AP and GAP

exhibit a plateau burning behaviour between pressure values of 7

and 12 MPa, like double base propellants. Chemical stability and

sensitivity test also within acceptable limits. FOX-7/ polyurethane

compositions with nitro plasticizers exhibit the best thermal stability.

Shock sensitivity test results of FOX-7 based propellant correspond

to values with a hazard division (HD) 1.3. However, the

mechanical properties need further improvement.

As limited studies are reported on FOX-7 based gun propellant,

the present work was undertaken to study FOX-7 as a component

of triple base gun propellant with NC as polymeric energetic

binder.

Experimental Section

Materials

NC-NG paste having volatile matter (VM) content 0.4% and

other ingredients weights are taken on dry weight basis for processing

the propellant batch. NC-NG paste, picrite and FOX-7 loaded

into incorporator for kneading and solvent (17-25%) along

with di-butyl phthalate to form homogenous and fully consistent

dough, warm water circulation started (38 - 40°C). Propellant processing

was carried out by well-established method. (Surjit Singh

Vol-II [12].

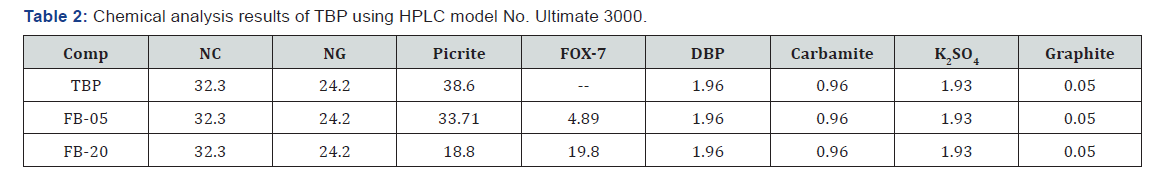

Chemical analysis of TBP was carried out using high

performance

liquid chromatography (HPLC) model No. Ultimate 3000.

This model of HPLC is manufactured by Dionex Softron GmbH,

Germering, Germany. The HPLC column has a neutral stationary

phase containing C18, octadecasilane with the dimensions of

250mm length, 4.6mm diameter and 5μm pore size. Mobile phase

included methanol: water (70:30) mixture. Propellant sample was

ground, and ether extract was prepared by heating the content in

water bath. It was injected into the HPLC column. The system is

run for a duration of 30 minutes by conditioning at a temperature

of 35°C at a standard flow rate of mobile phase of 1ml/min and

64 bar pressure in reverse phase. Content of polymeric binder NC,

graphite and K2SO4 in the propellant is calculated by difference. In

order to obtain only NC and graphite content in the propellant, the

residue of ether extract is treated with hot water. K2SO4 gets dissolved

in hot water that was estimated by well-known methods.

To estimate graphite, acetone is added in the remaining extract to

dissolve NC. Chemical analysis results are given below in Table 3.

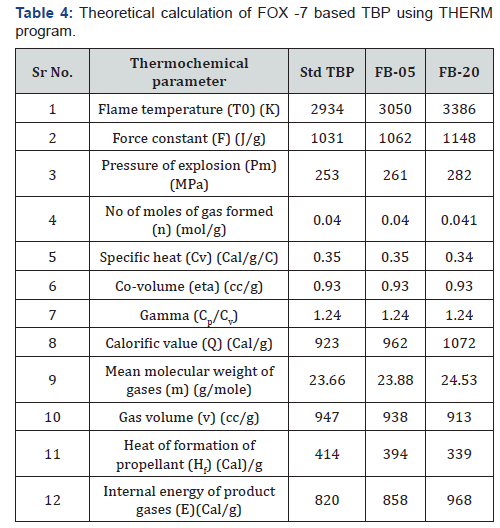

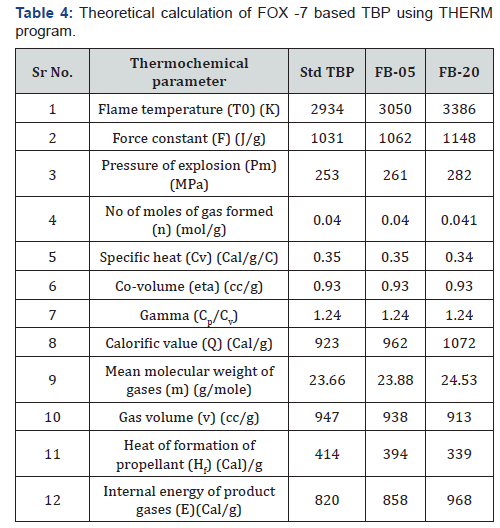

Thermo chemical parameters for all the experimental propellant

compositions that is processed are calculated using THERM

program of HEMRL are given in Table 4. In this program, some

basic thermodynamic equations that are reported for gun propellant

combustion have been used for calculations [13-19]. Approximate

determination of temperature of explosion is carried

out using computer program. Then the calculation of heat of reaction

of gas and its internal energy is carried out. Number of gram

atom/gram of C, H, N, O are given by well-known and reported

equation. The energy released at 2500K is evaluated making use

of well-reported combustion parameters for C, H, N, O. The major

products of propellant combustion are predicted viz. CO2, H2O, H2,

N2 gases and dissociation products are OH, H, NO, O. Calculation of

internal energy of these gases is carried out by applying standard

thermodynamic equations. Thereafter, other important and quite

relevant constants such as co-volume, force constant and heat of

combustion are calculated and compared with values reported in

the literature. Detailed research work involving computer program

had been published by K P Rao [12]. Researchers have been

using this program widely for approximate calculation of ballistic

parameters pertaining to gun propellants [20-24].

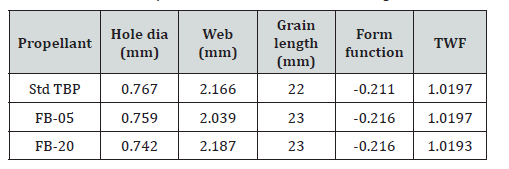

Measurement of dimensions of dried propellant grain was

carried out using Vaiseshika Zoom Stereoscopic Microscope

Type 7004 TNC Sr. No. 99075 having resolution 7X to 60X manufactured

by M/s Vaiseshika Electronic Devices, Ambala Cantt,

Haryana, India. The propellant grain is held in different positions

under the microscope which is connected to a programmed computer

and image is frozen and thereafter various dimensions such

as web size, hole size, grain diameter, length etc. are measured in

mm by moving the crosswire from point to point in the frozen image.

Movement of crosswire across the image gives the length or

distance between the two selected points on the image that is displayed

and recorded by a programmed computer connected to the

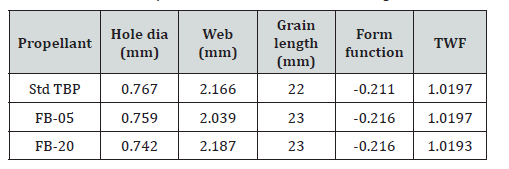

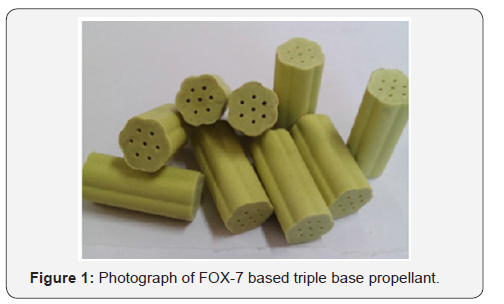

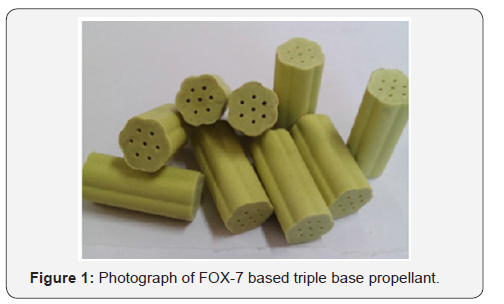

microscope. Geometrical parameters of FOX 7 based TBP grains

are tabulated in Table 5. Photograph of a few propellant grains

taken using camera make Sony Japan. Model No. Cyber-shotDSC-

S980, 12.1 Mega pixel, Optical zoom 4X is placed at Figure 1.

Form function is a measure of surface area of the

propellant

grain and theoretical web factor (TWF) is the ratio of ballistic web

to geometric web is calculated using available computer program

[11,12]. Input parameters like grain geometry, hole size, diameter,

length: diameter ratio is given as input parameters for calculation

and form function and TWF are obtained as output parameters.

Mechanical properties testing was carried out using Hounsfield

Universal Testing Machine H25KN, New York, US. Length: diameter

(L/D) ratio of propellant grain was adjusted to 2.0 and conditioned at

+21, -20 & +55°C for 4 hours. Mechanical properties viz.

compressive strength (CS) and % compression of the propellant

grains was determined.

Impact sensitivity and test was carried out using BAM IM Fall

Hammer apparatus make Chilworth Technology, UK, with 2kg

drop weight. Friction sensitivity test was conducted using BAM FR

Friction test apparatus, make Chilworth Technology, UK. Similarly,

autoignition temperature was determined using Wood’s metal

bath. During all the three tests propellant sample was powdered

by grinding and 150-300μm particle size was taken evaluation

[6,25].

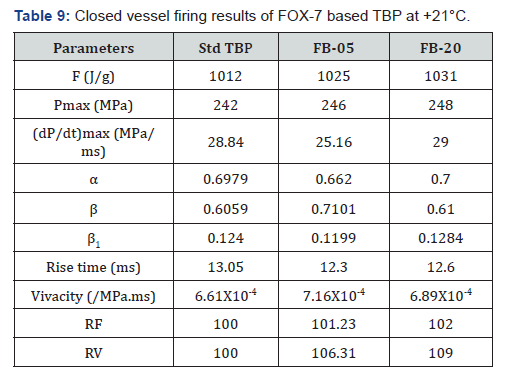

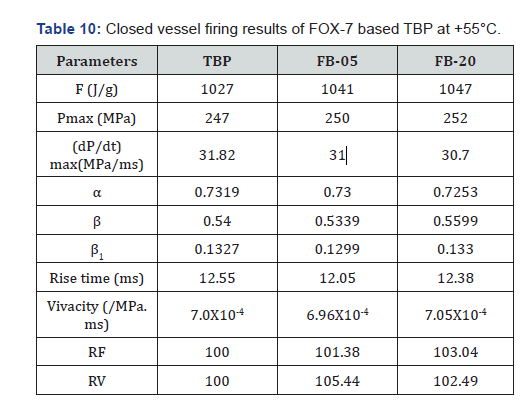

Closed vessel evaluation of FOX-7 based propellant along with

standard TBP (Std TBP) was carried out at 0.2g/cc loading density

in 700cc CV [26] after conditioning at +21, -20 & +55°C for 24

hours to determine ballistic parameters such as Pmax, force constant,

(dP/dt)max, pressure index (α), burning rate coefficient (β),

rise time, vivacity, relative force (RF) and relative vivacity (RV)

[19,27]. Measurement of pressure during CV firing was done using

tourmaline piezo-electric gauge. 1.2g gunpowder was used to

ignite the main propellant charge. Nearly 4 ampere current was

passed through a thin nichrome wire having length 22-25mm connected

across the firing electrodes closed vessel in order to ignite

the gunpowder which then ignites the propellant charge [28,29].

Results and Discussion

Chemical analysis results of TBP using HPLC is given in Table

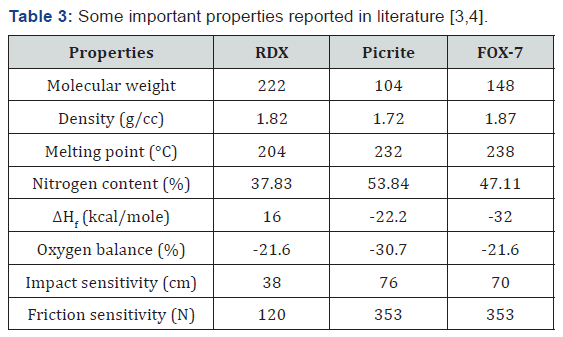

2. Some important properties are reported from literature [3,4]. It

shows that FOX-7 has higher density and oxygen balance as compared

to picrite. Result of theoretical calculation (Table 4) shows

that, most of the parameters such as flame temperature, force

constant, chamber pressure, calorific value, and mean molecular

mass are increasing for FOX-7 based propellant compositions as

compared to standard TBP which do not contain FOX-7. Geometrical

parameters of propellant grains (Table 5) shows that web

size, hole size, diameter, length and form function for FOX-7 based

compositions grains are comparable to the Std TBP grains.

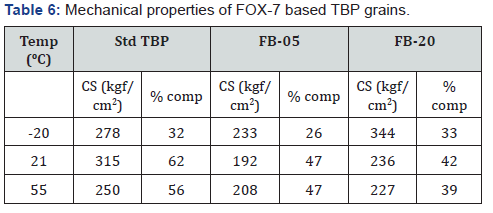

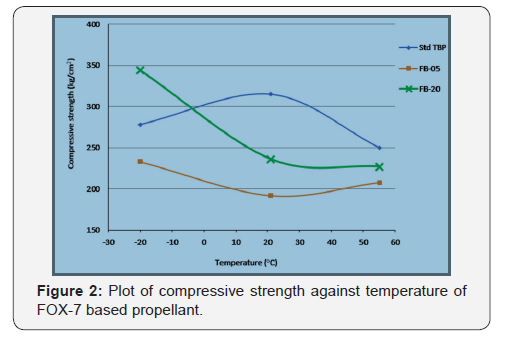

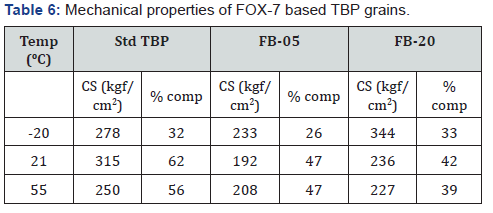

Mechanical properties such as compressive strength (CS) and

% compression after conditioning at +21, -20 & +55°C for four

hours are given in Table 6. The result shows that incorporation of

FOX-7 at 5% level bring down the CS whereas increase in FOX-7

content to 20% level results in improvement in CS at all the temperatures.

The CS at -20°C for 20% FOX-7 based composition is

more than that of even Std TBP. However, CS is increasing as the

amount of FOX-7 is increased in the propellant grain composition.

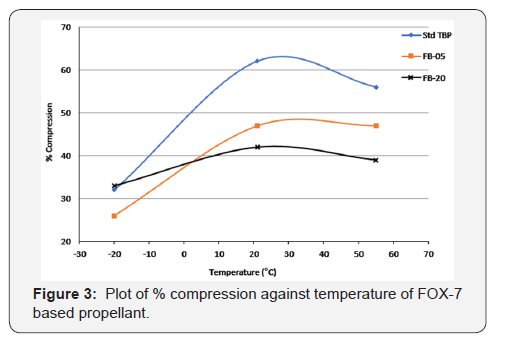

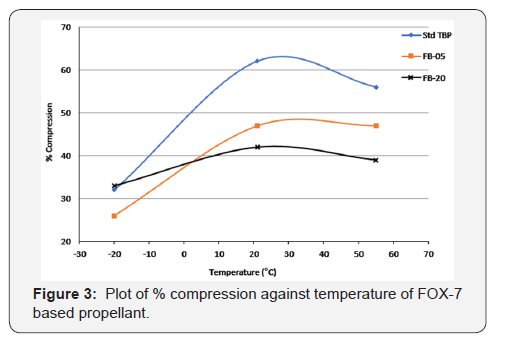

Incorporation of FOX-7 brought down the % compression at

+21°C. These results suggest that incorporation of FOX-7 renders

the TBP hard at sub-zero conditioning temperatures probably

due to reinforcement by FOX-7 particles involving physical forces

(hydrogen bonding). It is possible that microcracks may be developing

in the FOX-7 based TBP grains at sub-zero conditioning

temperatures offering greater burning surface resulting in combustion

stability and near to temperature independent ballistics

of gun propellant. This is on the lines of the work already reported.

The results also suggest that FOX-7 based TBP can retain structural

integrity even at higher temperature thereby preventing the

accidental damage to gun.

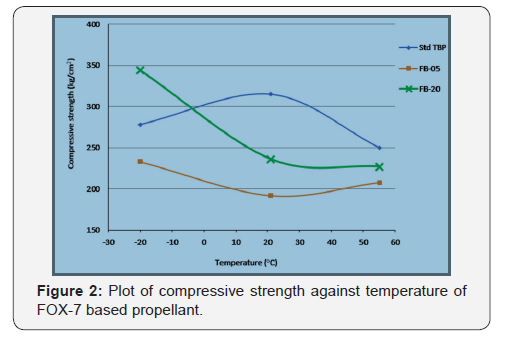

FOX-7 based propellant grains are stronger at -20oC

and weaker

at higher temperatures than Std TBP as the value of CS is higher

at sub-zero temperature and lower at +55°C. The performance at

+21 & +55°C is almost similar. Values of CS are plotted in Figure

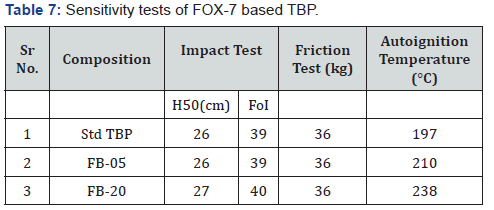

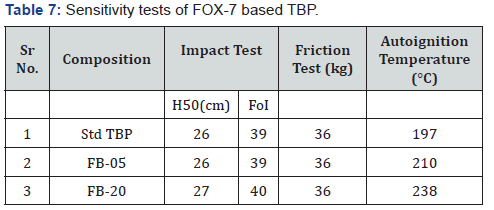

2.Impact, friction as well as auto-ignition temperature test results

are given in Table 7. Auto-ignition test results bring out decrease

in vulnerability to thermal stimulus of propellant on incorporation

of FOX-7. These results are in line with the reported studies

Waldemar A. Trzciński [30]. FOX-7 did not have adverse effect

on impact and friction sensitivity of the propellant unlike RDX/

HMX. This may be due to stability gained by the molecules after

each oxygen atom of the nitro groups involved with two hydrogen

bonding in FOX-7 molecules resulting in two intra-molecular and

six inter-molecular hydrogen bonds [31] Figure 3.

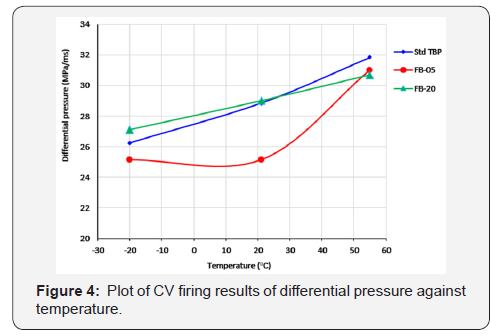

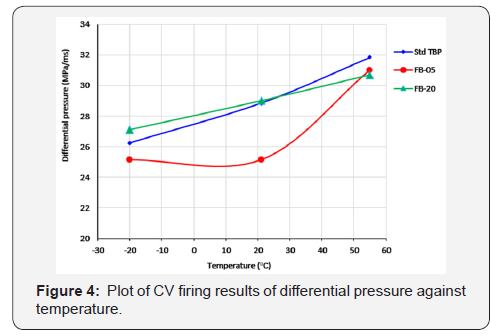

As depicted in Figure 4, rate of change of pressure i.e. differential

pressure attains a maximum value for every composition

during CV firing is denoted in terms of (dP/dt)max. The value of

(dP/dt)max is lowered for FB-20 at +55°C whereas it is increased

at -20°C and almost coincides at 21°C with that of Std TBP. This

behaviour of FOX-7 based TBP indicates a trend towards low temperature

coefficient propellant.

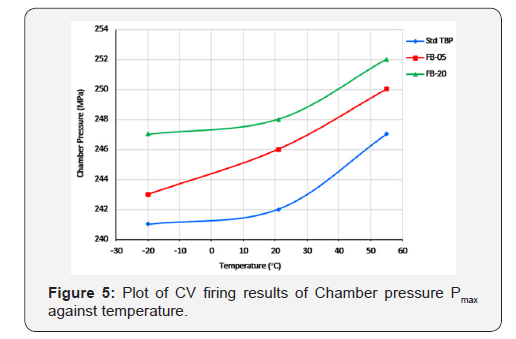

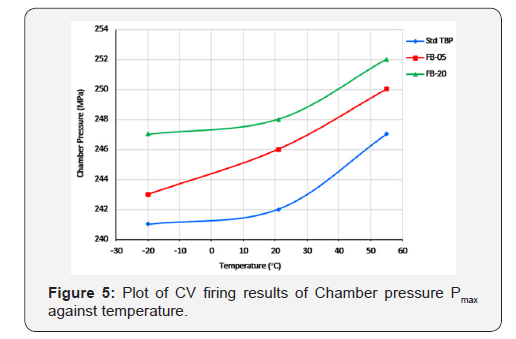

Chamber pressure was found marginally higher for FB-05 and

FB-20 compositions compared to Std TBP evaluated during this

work at -20°C and 21°C, as shown in Figure 5 whereas it is found

to be marginally increased for FB-05 composition at +55°C. This

may be due to brittleness of FOX-7 based propellant composition

which gives rise to increase in surface area and increased burn

rate. Increased burn rate increases the amount of gases thereby

increasing the gaseous pressure. This trend in pressure indicated

that FOX 7 based TBPs are showing low temperature sensitivity

[32]. This result shows that FOX-7 based TBP can be used in large

calibre guns without hazards.

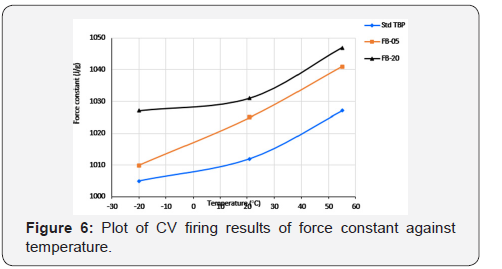

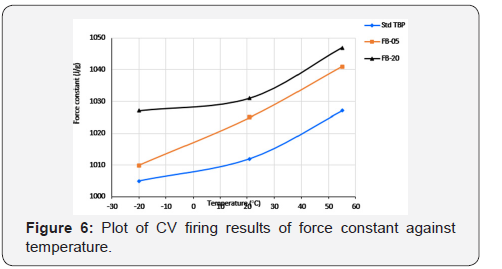

Force constant which is a measure of propellant energy is almost

same for FB-20 composition at -20°C and at 21°C as compared

to Std TBP and FB-05 composition whereas it is increased

at +55°C. The graph is plotted in Figure 6. This behaviour of FOX-7

based TBP indicates a trend towards low temperature coefficient

propellant in sub-zero temperature region. This may be due to

hardening of FOX-7 based propellant grain making it more brittle

propellant composition which gives rise in surface area and

increased burn rate. Increased burn rate increases flame temperature

and gaseous molecules move faster giving more force

or energy (Table 4) [30]. CV firing results bring out increase in

force constant with increase in FOX-7 content in the propellant at

replacement of picrite. This may be attributed to higher density

and superior oxygen balance (stoichiometry) of FOX-7 compared

to picrite.

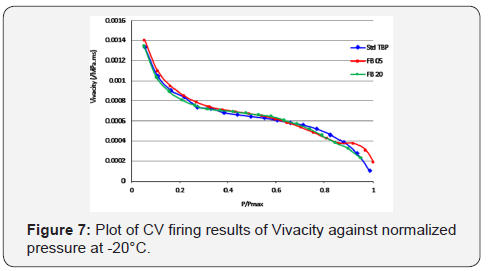

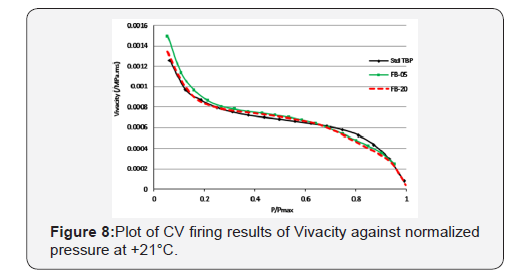

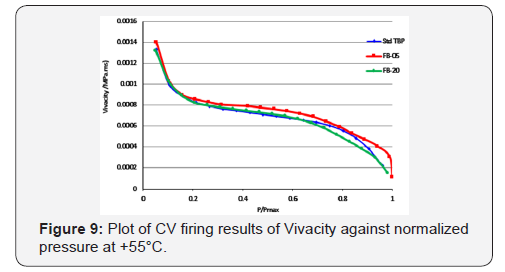

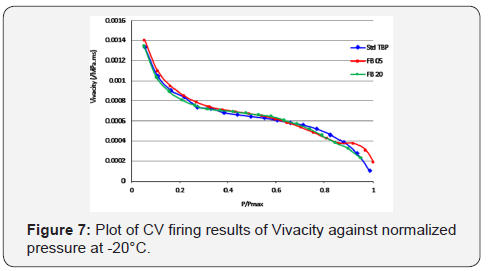

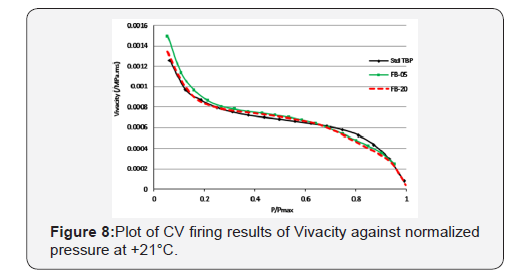

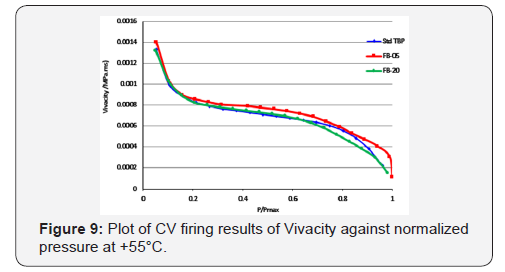

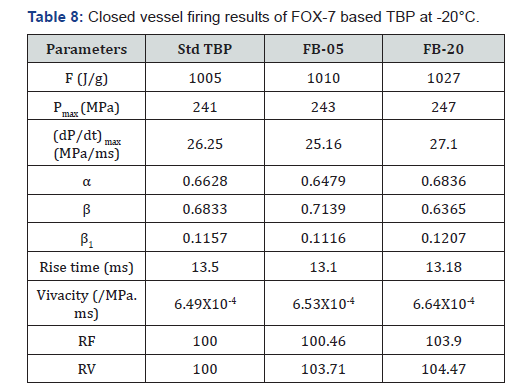

Dynamic vivacity expressed as [(1/P). (1/Pmax). (dP/dt)] is

plotted against normalized pressure (P/Pmax). A comparison of

Figure 7-9 corresponding to CV tests at -20, +21 and +55°C respectively

shows that graph of vivacity for FB-20 composition begins

on the lower side as compared to FB-05 and marginally higher

than Std TBP and it remains on the lower side for entire range

of normalized pressure. It indicates comparative lowering of the

production of gases at all temperatures of conditioning for FB-20

propellant composition and particularly at +55°C. This clearly

brings out the fact that FOX-7 based propellant composition has

the potential for exhibiting low temperature coefficient ballistic

parameters. Similar is the trend in case of RV as observed from the

graph between RV versus temperature shown in Table 8.

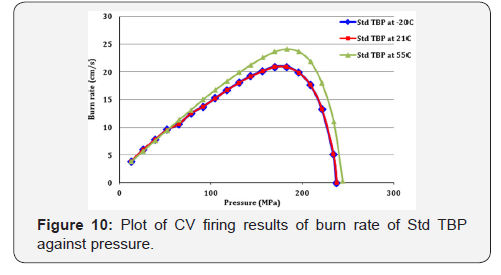

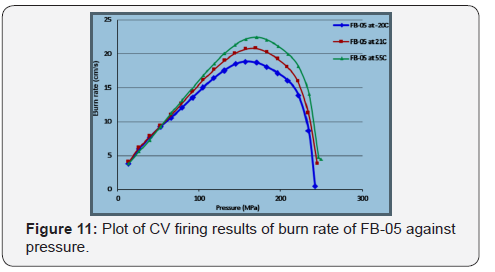

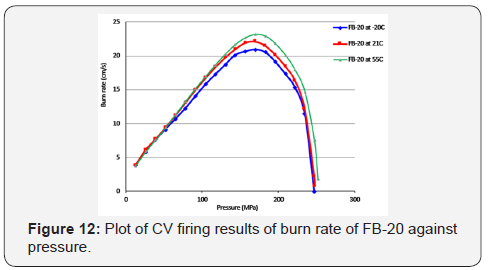

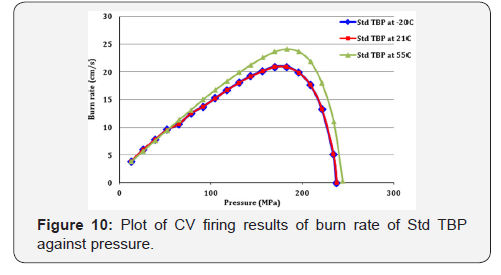

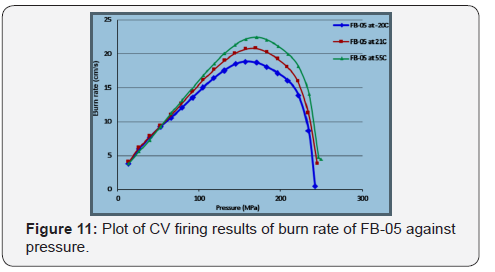

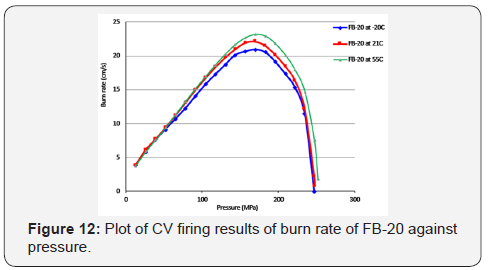

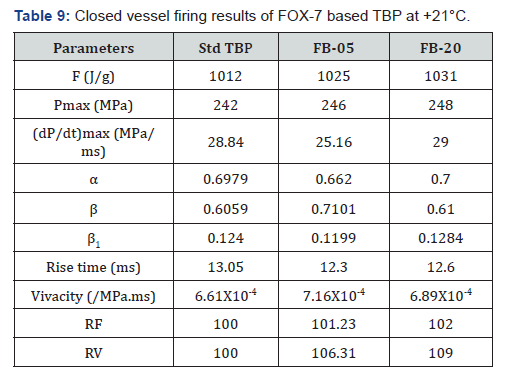

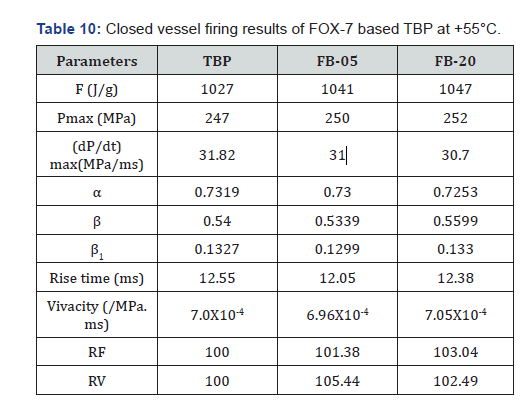

Burn rate versus pressure profile obtained during CV firing

of FOX-7 based propellant compositions at -20, 21 & +55°C respectively

plotted in Figure 10-12. Graph shows that burn rate

increases with increase of temperature and attains peak at certain

pressure and then falls off steeply even though the pressure increases

as the propellant gets consumed fully. It may be noted that

the burn rate is lowered as the FOX-7 content is increased in the

propellant compositions. Burn rate for FOX-7 based composition

FB-05 is reduced as compared to Std TBP; however, for FB-20 it

was close to that for Std TBP at -20°C whereas at +55°C for FOX-7

based composition gave marginally lower burn rates at Pmax compared

to Std TBP. These results are indicative of introduction of

temperature independent/less dependent combustion of FOX-7

based TBP. It increases the duration of combustion. This indicates

that pressure may act on the base of projectile for a longer duration

increasing its velocity [Table 9 & 10].

Conclusion

FOX-7 based gun propellant has given improved energetics

and ballistic properties as compared to conventional TBP. Force

constant, Pmax, (dP/dt)max, and RV are on the higher side as compared

to standard TBP propellant showing that loading density in

high caliber gun can be reduced to get the same muzzle velocity

and chamber pressure. Vivacity variation indicates lowering the

production of gases at all temperatures of conditioning of the FB-

20 propellant composition and the rate of generation of gases is

further lowered at higher temperatures as compared to Std TBP.

This clearly brings out the fact that FB-20 propellant composition

has the potential for exhibiting low temperature coefficient ballistic

parameters. Similar trend is observed in case of RV versus

temperature. Burn rate is lowered and the peak is broadened as

the FOX-7 content is increased in the propellant compositions

indicating increased duration of combustion. This indicates that

pressure may act on the base of projectile for a longer duration

increasing its velocity. The trends in ballistics observed bring out

the fact that FOX-7 has potential to impart less sensitive, temperature

independent characteristics in the TBP used for high calibre

gun.

For more Open Access Journals in Juniper Publishers please

click on: https://juniperpublishers.com

For more articles in Academic Journal of Polymer Science please

click on:https://juniperpublishers.com/ajop/index.php

For more Open Access Journals please

click on: https://juniperpublishers.com

Comments

Post a Comment