Wettability Properties of Biochar Added Wood/Polypropylene Composites-Juniper Publishers

JUNIPER

PUBLISHERS- Academic Journal of Polymer Science

Abstract

In an attempt to comprehend the outdoor application

potential of biochar reinforced wood and polypropylene composites, their

wettability properties were investigated. The localised water affinity

was measured through drop shape analysis in a Goniometer whereas the

comprehensive susceptibility towards water was done through a thickness

swell test. The results indicate that the addition of 12wt% of wood

waste (Pinus radiata) biochar to a wood and polypropylene composite had

the highest resistance towards water among the three component

composites. In general, the predilection towards water increased with an

increase in the amount of biochar in the composites. It is recommended

to produce the biochar with low pyrolysis temperature (yielding a more

hydrophobic biochar) to develop composites with acceptable water

opposing properties.

Keywords: Wood; Polypropylene; Biocomposites; Biochar; Wettability; GoniometerIntroduction

Increased environmental awareness and diminishing

natural resources have together provided the impetus to explore and use

materials that are waste based. These motivations coupled with

regulation-based impetus enforced by government and regional councils

have led to the research and development of innovative waste-derived

products [1,2]. Biochar is a renewable material which can be produced by

valorising any organic biomass (e.g. forestry, crop residue, poultry

waste, dairy manure) in an oxygen free environment by a pyrolysis

process [3]. Until now, the application of biochar was limited to soil

amendment, filtration and contaminant/heavy metal removal [4]. In order

to make its application diverse, the biochar derived from organic wastes

was incorporated with conventional wood and polymer composites to yield

wood polymer biochar composites (WPBC) [5-7]. Through these works, the

authors have demonstrated that biochar could be applied as reinforcement

in wood polymer composites to improve their mechanical, thermal and

fire properties as well as to reduce the use of costly coupling agents.

The development of wood polymer and biochar composites requires the

knowledge of its physico-mechanical properties. The mechanical, chemical

and thermal properties of the WPBC were evaluated by Das et al. [5]

However, prior to the application of this composite, it is critical to

comprehend the endurance of WPBC towards external environment.

Similarly, to other wood polymer composites (WPCs), WPBC can be applied

in making decking material, windows and door panels and automotive

parts [8]. These types of applications may expose the WPBC to rainfall

and humid conditions, hence, the wettability properties of WPBC should

be investigated.

WPBC consists of three distinct constituents

(biochar, wood and polymer) that differ in their interactions with

water. The physical and chemical properties of the different

constituents of WPBC may stay distinct macroscopically in the final

product while exhibiting synergistic material properties [9]. As a

result, individual components would have an additive effect on the final

physico-chemical nature of the composites. This would consequently

affect the overall wettability properties of WPBC.

The main objective of the study was to investigate

the resistance of WPBC towards water in general and specifically how

different loading amounts of biochar in the composite affected the

resulting wettability.

Materials and Methods

The detail description of the process and methods

used to develop biochar added wood and polymer composites can be found

in Das et al. [5]. Briefly, the constituents were dry blended, then melt

blended in an extruder and finally compression moulded to manufacture

the samples. Six different samples were manufactured containing 0, 6,

12, 18, 24, and 30 wt% biochar, which was produced by pyrolysis of waste

pine wood. The samples were named WPC (control, 0 wt% biochar

reinforcement), WPBC 6; WPBC 12; WPBC 18; WPBC

24 and WPBC 30, based on the weight percentage of biochar in

them. After manufacturing of the WPC and WPBCs, wettability

properties were investigated.

Localised wettability was measured in a Goniometer (KSV

instruments, Finland, Model: CAM101, software: Attension

Theta) through drop shape analysis. The contact angles of

deionised (D.I.) water (volume= 4μl) was measured (mean

of right and left contact angles) on a flat sample surface at an

interval of 60 s for a period of 20min. Swelling tests were carried

out according to ASTM D-7031-04 protocol. Three specimens of

each formulation were selected at random and bone dried in a

convection oven for 24h at 105 °C. This was followed by cooling

the samples to room temperature in a desiccator. The specimens

were then immersed in D.I. water for 24h at room temperature.

The excess water on the surface was wiped off by tissue paper.

The values of the thickness swelling in percentages were

calculated using the following equation:

where,

TS= Thickness swell in percentage

T(f)= Final thickness

T(i)= Initial thickness

Results and Discussion

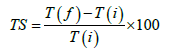

Figure 1 shows the localised water absorption of the WPC

and WPBCs measured with a Goniometer. Figure 1a shows the

changes in contact angles of water on the composite’s surface

with respect to time, whereas, Figure 1b shows the difference

in initial and final contact angles for each sample. The initial

contact angle at 1min was not indicative of the samples’ affinity

(i.e. degree of absorption) towards water. The noteworthy

observation is how the contact angle changed i.e. became

smaller with respect to time. It can be observed from Figure 1a

that all the composites follow a similar pattern when wettability

towards water is concerned: with time, the contact angle

decreased representing the movement of water into the surface

of the composite and evaporation.

The composites’ affinity towards water can be understood

by the change in the initial and the final contact angle of water

droplet. The higher the difference is between the final and the

initial value of contact angle, the higher is the affinity towards

water. It is clear from the Figure 1b that the composites having

higher amount of biochar (WPBC 18, 24 and 30) had a higher

affinity towards water. This is attributed to the lower amount

of the hydrophobic polymer (i.e. polypropylene) in the blends.

WPBC 30 had the highest affinity towards water, as the

polypropylene content was the lowest among all blends. Though

biochar can be hydrophobic provided they are made at lower

pyrolysis temperature (<400 °C) [10], the one used in this study

was made at 450 °C. As the pyrolysis temperature is raised, the

volatiles escape creating pores on biochar surface. Water can be

absorbed into these pores through capillary action. Hence, the

higher temperature biochar’s inherent affinity towards water

and the lower content of the hydrophobic polypropylene made

the composites with higher amount of biochar more susceptible

to water. Additionally, the increase in the amount of biochar

also increased the proportion of wood in each blend [5,11]. The

prominence of the wood component further made the composite

samples containing higher amounts of biochar more susceptible

to wetting. This is because the wood is naturally hygroscopic due

to formation of hydrogen bonds between wood biopolymers and

the water molecules [12].

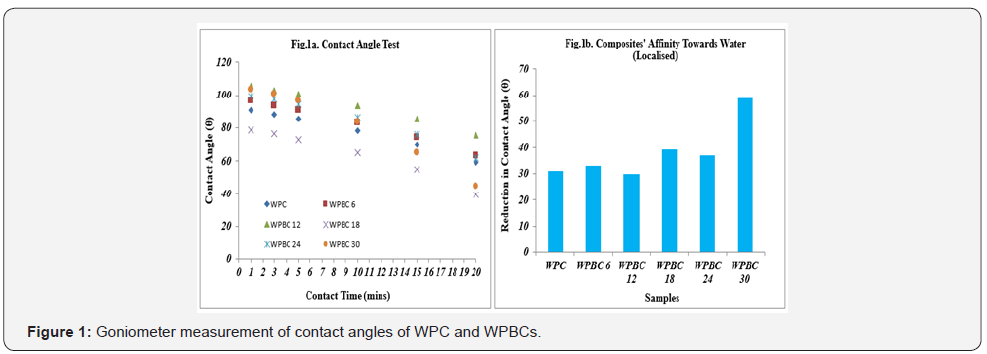

Figure 2 shows the shape of the water droplet, as seen

through the goniometer telescope, on the flat surfaces of each

samples at intervals of 1, 3, 5, 10, 15, and 20min. WPC (control)

was most resistant to water compared to all the composites

containing biochar. Similar to the observation made from

Figure 1a and 1b, the contact angles drastically decreased in the

WPBC samples containing more biochar (WPBC 6, 18, 24, and

30). An exception was WPBC 12, where the amounts of wood,

biochar and polymer were optimal to provide it with maximum

resistance towards water. WPBC 12 and WPC had an almost

similar resistance towards localised water absorption. This

observation corroborates the results of Figure 1b.

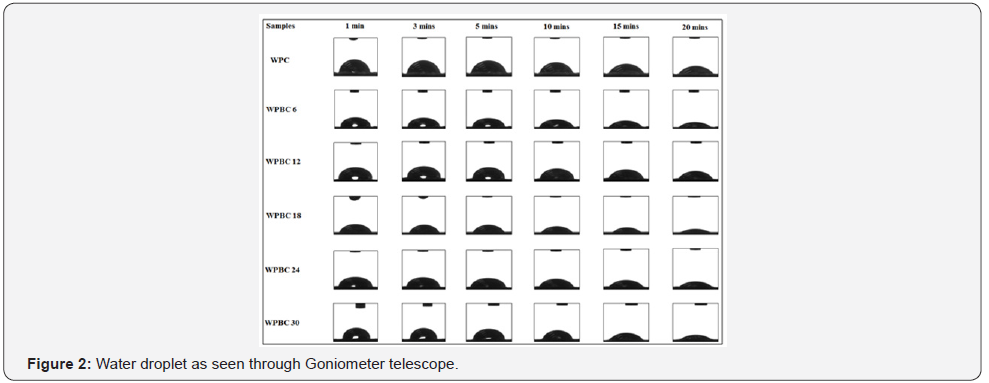

Figure 3 shows the percentage thickness swell of the

samples after immersion in water for 24h. It can be seen that,

in general, there was a gradual increase in the thickness swell

as the amount of biochar increased in the samples of WPBC (not

considering WPBC 6). This trend is attributed to the increased

amount of less hydrophobic biochar, decreased amount of

hydrophobic polypropylene and increased contribution of

hydrophilic wood [5]. The thickness swell value for WPBC 6

was the highest among all WPBCs and this was probably due to

the presence of voids formed during its manufacturing [5]. The

voids acted as pockets for the increased collection of water and

consequently increased in size leading to WPBC 6’s overall high

thickness swell. Theoretically, WPBC 30 should have had the

highest swelling value but from Figure 3 it can be observed that

both WPBC 6 and 30 have identical swelling values (13.8 and

13.8%, respectively). Hence, it becomes clear that the presence

voids from manufacturing are detrimental for the wettability

properties of composites having biochar additive. On the other

hand, the composite WPBC 12 had the lowest swelling value

(12.7%) among all WPBCs, which is in agreement with the

observation made in Figure 1 & 2.

The swelling of any WPBCs was higher than the control

(WPC). This is not favourable when application of WPBC in

field conditions is considered. However, to make a composite

resistant to the swelling, it is recommended to use biochars

that are made at lower pyrolysis temperatures (<400 °C).

Biochars made at lower temperatures have pores that are

clogged by the tar, which is unable to escape during pyrolysis.

Due to the presence of tar, these biochars exhibit hydrophobic aliphatic groups on their surface [13]. This clogging

also makes the number of pores and the surface area smaller.

Hence, the collective effect of hydrophobic tar on the surface

and pore clogging lowers the affinity of the biochar towards

water [14]. On the other hand, biochar made at lower pyrolysis

temperatures tend to have a lower content of elemental carbon

and lower hardness [4,15], which consequently reduces the

quality and reinforcement ability of this biochar. In order to make

a high-quality biocomposite, an optimal production temperature

of biochar should be chosen to obtain a hydrophobic biochar

containing a high amount of elemental carbon and having an

increased hardness.

Conclusion

From the investigation conducted on the wettability

properties of wood and polypropylene composites having a

biochar additive, the following conclusions can be drawn:

i. The addition of 12wt% of biochar in a wood and

polymer composite bestows it the highest resistance towards

water.

ii. The increase of biochar content in the composite makes

it more susceptible to water

iii. High production temperature of biochar increases its

affinity towards water (absorption through capillary action

of pores); hence such biochar type is not recommended for

reinforcing composites aimed for the robust hydrophobicity.

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment