Thermodynamics of Biomass-Based Solid Fuels-Juniper Publishers

JUNIPER

PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

In this paper, solid fuels made of plant biomass were

studied as an alternative to fossil coals. For this purpose,

experimental and calculation methods were applied to determine the

standard change of internal energy or specific energy of combustion

)(ociUΔ standard enthalpies of combustion ()ociHΔ and formation ()ofiHΔ

for individaual components of plant biomass (lignin, cellulose,

hemicelluloses, extractives, etc.), as well as of some additives of

solid biofuels. The experiments were carried out using an oxygen bomb

calorimeter, whereas calculations were performed by the equation:

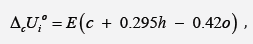

where E = -413 kJ/mol, c, h and o is number of atoms

C, H and O, respectively, in molecule of organic substance or in repeat

unit of polymer. Using the results obtained for individual components,

the standard thermodynamic characteristics (TDC), oY , of various

biomasses and their based fuels were found according to additivity rule,

as follows: ooiiYwY=Σ , where iw is weight part of the component in the

biofuel. The results revealed that calculated TDC the solid fuels were

close to experimentally obtained characteristics. The obtained data

evidence on adequacy of the additivity rule to evaluate the TDC of solid

biofuels. It has been also found that fuel pellets consisting of plant

biomass and additive of plastic binders are the most promising solid

fuels, since they provide a higher value of thermal energy and increased

energy density than the biomass only.

Keywords: Plant biomass, Biofuel; Cellulose; Hemicelluloses; Lignin; Extractives; Thermodynamic characteristics; Calorimetry; Calculation

Introduction

Currently, the main solid fuels are fossil coals,

which provides 28-30% of annual energy consumption in the world, about

160-180EJ [1]. To generate such energy, more than 6 billion tons of coal

are burned each year. However, this fossil source of energy is not

reproduced in nature, and therefore its reserves are permanently

depleted. Besides, the burning of coals is accompanied by emission of

greenhouse gas - carbon dioxide, in the huge volume of 1700-1800m3 from

each ton, which can exacerbate the problem of global warming [2].

An alternative to coal can be a solid fuel based on

plant biomass, which in contrast to this fossil fuel, is reproduced in

nature. The term “biomass” means here a variety of plant materials, as

well as their residues and wastes [3]. Diverse types of biomass can be

used to produce of solid fuels such as soft- and hardwood; herbaceous

plants (e.g. Miscanthus, Switchgrass, Bermuda grass, etc.); forest

residues (e.g. sawdust, twigs, shrubs, etc.); residues of agricultural

plants (e.g. stalks, husks, cobs, etc.); residues, waste and trash of

textile, pulp, paper, cardboard and plants, as well as algae biomass,

etc. Total amount of available biomass aimed especially for energy

production is estimated at 8-10 billion tons [4].

As is known, all constituents of biomass are

photosynthesized in chlorophyll pigment of plant leaves from carbon

dioxide and

water, absorbing red and blue-violet sunlight [5,6]. In fact, plant

biomass can be considered an accumulator of solar energy captured during

photosynthesis. To generate the heat energy, the biomass is burned,

resulting in the release of accumulated solar energy. A specific feature

of the biomass that it is neutral for emission of carbon dioxide, since

its combustion produces the same amount of this greenhouse gas as it

was absorbed from the atmosphere during photosynthesis.

However, the plant biomass is a heterogeneous

material having low bulk density, which consists of pieces of different

shapes, sizes and compositions. These negative features lead to

deterioration in fuel properties - unstable calorific value, low density

of thermal energy and insufficient combustion efficiency [7]. To

increase the low energetic density, the loose biomass should be

converted into dense pellets. Nevertheless, even after compaction, other

negative biomass characteristics remain, such as low calorific value

and sensitivity of the solid fuel to water absorption. A promising way

to improve the fuel features of biomass is the use of plastic binders in

the pelletization process [8]. As is known, large amounts of plastic

waste about 250-300 million tons are thrown out annually and pollute the

environment [9]. After separation of PET bottles from plastic debris,

the main fraction of the plastic waste consists of polyolefins, which

can be used as additive to biomass for co-firing.

The use of biomass and its mixtures with polymer binders

for production of solid fuels requires knowledge of standard

specific energy of combustion (  )

and other Thermodynamic

Characteristics (TDC). Numerous attempts have been performed

to determine the

)

and other Thermodynamic

Characteristics (TDC). Numerous attempts have been performed

to determine the  values for certain types of biomass and

synthetic polymers using the precise experimental method,

namely a combustion of sample in a bomb calorimeter [10-13],

as well as various calculation methods [13-16]. However, the

calorimetric measurements are lengthy and requires multiple

repetitions to obtain a reliable result; besides bomb calorimeter

is a complex, expensive and not always available device. On the

other hand, to calculate the

values for certain types of biomass and

synthetic polymers using the precise experimental method,

namely a combustion of sample in a bomb calorimeter [10-13],

as well as various calculation methods [13-16]. However, the

calorimetric measurements are lengthy and requires multiple

repetitions to obtain a reliable result; besides bomb calorimeter

is a complex, expensive and not always available device. On the

other hand, to calculate the  value for each biomass type, its

own equation has been proposed [13-15]. Since an unlimited

number of different types of biomass and its based compositions

exists, an unlimited number of experiments or calculations are

required to determine the TDC of various solid fuels, which is

impossible to realize.

value for each biomass type, its

own equation has been proposed [13-15]. Since an unlimited

number of different types of biomass and its based compositions

exists, an unlimited number of experiments or calculations are

required to determine the TDC of various solid fuels, which is

impossible to realize.

)

and other Thermodynamic

Characteristics (TDC). Numerous attempts have been performed

to determine the

)

and other Thermodynamic

Characteristics (TDC). Numerous attempts have been performed

to determine the  values for certain types of biomass and

synthetic polymers using the precise experimental method,

namely a combustion of sample in a bomb calorimeter [10-13],

as well as various calculation methods [13-16]. However, the

calorimetric measurements are lengthy and requires multiple

repetitions to obtain a reliable result; besides bomb calorimeter

is a complex, expensive and not always available device. On the

other hand, to calculate the

values for certain types of biomass and

synthetic polymers using the precise experimental method,

namely a combustion of sample in a bomb calorimeter [10-13],

as well as various calculation methods [13-16]. However, the

calorimetric measurements are lengthy and requires multiple

repetitions to obtain a reliable result; besides bomb calorimeter

is a complex, expensive and not always available device. On the

other hand, to calculate the  value for each biomass type, its

own equation has been proposed [13-15]. Since an unlimited

number of different types of biomass and its based compositions

exists, an unlimited number of experiments or calculations are

required to determine the TDC of various solid fuels, which is

impossible to realize.

value for each biomass type, its

own equation has been proposed [13-15]. Since an unlimited

number of different types of biomass and its based compositions

exists, an unlimited number of experiments or calculations are

required to determine the TDC of various solid fuels, which is

impossible to realize.

For this reason, another approach should be used. As is

known, any plant biomass contains cellulose, hemicelluloses,

lignin, extractives and small amounts of some other substances.

Besides, mixed solid fuel can contain also plastic additive. Thus,

to find the TDC of solid fuels made of biomass or its mixture with

plastics, it is sufficient to determine the TDC for limited number of

individual components and their content in the sample and then

use the additivity rule.

Although some TDC of individual components of plant biomass

has been studied by various researchers, the obtained results were

insufficiently reliable since they were varied over a wide range.

For example, a considerable variation in the  values for lignin

samples, from 20 to 29 kJ/g was observed [15,17,18], whereas

the variation in specific energy of combustion for cellulose and

hemicellulose samples was from 16.9 to 18.6 kJ/g [10,15,17-19].

values for lignin

samples, from 20 to 29 kJ/g was observed [15,17,18], whereas

the variation in specific energy of combustion for cellulose and

hemicellulose samples was from 16.9 to 18.6 kJ/g [10,15,17-19].

values for lignin

samples, from 20 to 29 kJ/g was observed [15,17,18], whereas

the variation in specific energy of combustion for cellulose and

hemicellulose samples was from 16.9 to 18.6 kJ/g [10,15,17-19].

values for lignin

samples, from 20 to 29 kJ/g was observed [15,17,18], whereas

the variation in specific energy of combustion for cellulose and

hemicellulose samples was from 16.9 to 18.6 kJ/g [10,15,17-19].

The purpose of this study was an accurate determination of

standard thermodynamic characteristics of individual components

of biomass, as well as of some plastic binders, in order to use the

obtained results to evaluate the TDC of solid biofuels by means of

additivity rule.

Experimental

Samples

Various types of biomass were used such as chips of spruce,

pine and poplar, corn, wheat straw, switchgrass and bagasse of

sugarcane, as well as waste paper and cardboard. The biomass

samples were cut, knife-milled and screened through a sieve to

obtain the fraction of 1-2mm.

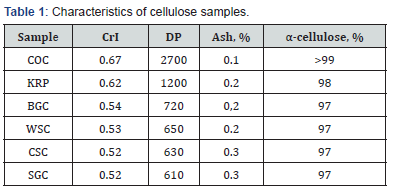

The samples of bleached chemical grade Cotton Cellulose

(COC) and Kraft Pulp (KRP) were used. Besides cellulose was

isolated from Bagasse (BAC), Wheat Straw (WSC), Corn Stalks

(CSC) and Switchgrass (SGC) by a two-stage pulping using dilute

nitric acid and alkali with additional bleaching [20]. The cellulose

samples were additionally purified by extraction with organic

solvents, chelating agent (EDTA), boiling 2% NaOH and boiling

water to neutral pH; then samples were rinsed with deionized

water, ethanol and dried at 380 K to constant weight. The main

characteristics of the samples (crystallinity index CrI, degree of

polymerization DP, content of ash and α-cellulose) are shown in

the Table 1.

Samples of starch, pentosans, hexosans, Abietic Resin Acid

(ABA) and Triglycerides of Stearic (TGS), palmitic (TGP), were

supplied from Sigama-Aldrich. Klason lignin was isolated from

various biomasses using standard TAPPI method T222. Powdered

polyolefins were supplied from Ineos Olefins and Sigma-Aldrich.

Pelletization

The ground biomass was blended with powdered polyolefin,

and the mixture was compacted under pressure 50 MPa at

temperature of 445-450K for 1-2min. For comparison, the

pelletized biomass was also prepared under the same conditions.

Characterization of samples

Chemical composition of biomass samples was studied by

standard NREL methods [21]: LAP-001 (total solids), LAP-002

(cellulose and hemicelluloses), LAP-003 (lignin), LAP-005 (ash)

and LAP-010 (extractives). Bulk density was tested by standard

method ASTM E-873. Average degree of polymerization (DP) of

cellulose was measured by the viscosity method using diluted

cellulose solutions in Cadoxen [22]. Index of cellulose crystallinity

(CrI) was estimated using Jayme and Knolle method [23].

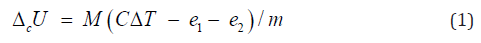

Combustion calorimetry

Combustion of samples in pelletized form (cca. 1g) was

carried out in a bomb calorimeter Parr-1341 at oxygen pressure

of 3 MPa with 1ml of added deionized water. The temperature and

its rise (ΔT ) were measured with accuracy ±0.001 K. The value of

energy equivalent of the calorimetric system (C) was determined

by combustion of standard benzoic acid. The correction of internal

energy change (ΔcU) for ignition (e1), as well as for formation and

dissolution of nitric acid (e2) were taken into account:

where m is true mass of sample, M is molecular mass of

substance or repeat unit of polymer.

To obtain the standard value of specific energy of combustion

the Washburn’s correction was introduced. When the

standard enthalpy of combustion

the Washburn’s correction was introduced. When the

standard enthalpy of combustion  is calculated, the

correction was introduced for change in number of moles of gases

before and after combustion. The standard enthalpy of formation

is calculated, the

correction was introduced for change in number of moles of gases

before and after combustion. The standard enthalpy of formation

was calculated by the known equation:

was calculated by the known equation:

the Washburn’s correction was introduced. When the

standard enthalpy of combustion

the Washburn’s correction was introduced. When the

standard enthalpy of combustion  is calculated, the

correction was introduced for change in number of moles of gases

before and after combustion. The standard enthalpy of formation

is calculated, the

correction was introduced for change in number of moles of gases

before and after combustion. The standard enthalpy of formation

was calculated by the known equation:

was calculated by the known equation:

where n(CO2) and n(H2O) are number of moles of CO2 and H2O

in combustion reaction; o

f Δ H (CO2, g) = -393.51 kJ/mol and o

f Δ H

(H2O, l) = -285.83 kJ/mol are standard enthalpies of formation of

carbon dioxide and liquid water.

For each sample three experiments were performed to obtain

the reliable TDC.

Results and Discussion

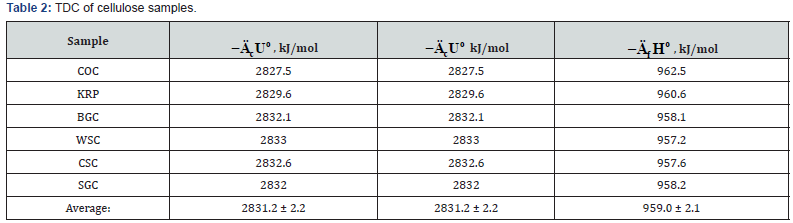

The results of calorimetric determination of standard

thermodynamic characteristics of individual components of plant

biomass are shown in Tables 2-5.

As can be seen from Tables 2 and Table 3, when determine

the TDC of carbohydrates the relative divergence between

combustion energies or enthalpies was small, about ±0.1%.

The obtained average values of TDC were in the range given in

literature [10,16,19,24].

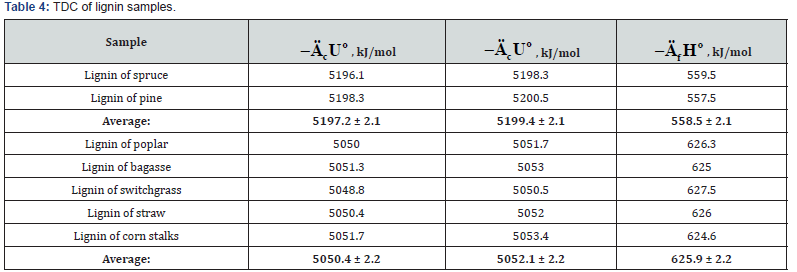

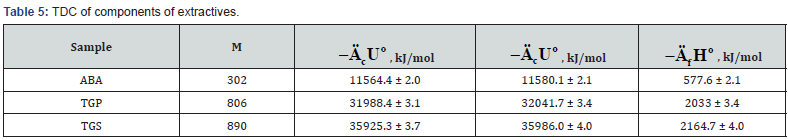

The study of lignin samples has shown (Table 4) that specific

energy of combustion for lignins of softwood were higher than

the corresponding values for lignins isolated from hardwood

(Lignin-S) and herbaceous plants (Lignin-H). The study of

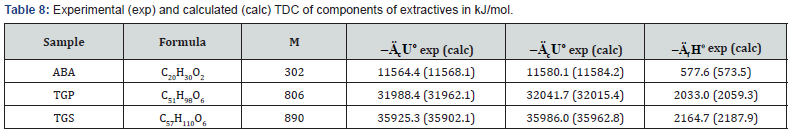

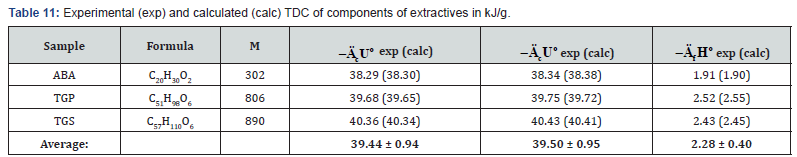

components of extractive substances (resin acids, e.g. ABA, and

various lipids) has shown that standard energy and enthalpy

of combustion was proportional to molecular mass of these

substances (Table 5).

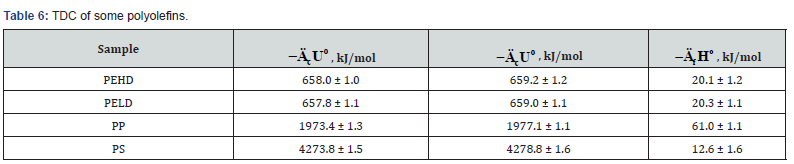

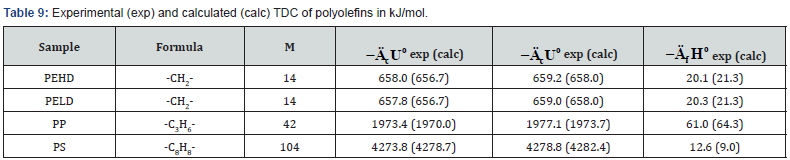

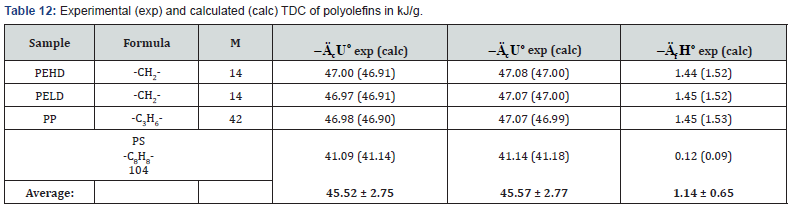

The determined TDC of some polyolefins (Table 6) are

confirmed by literature data [13,25].

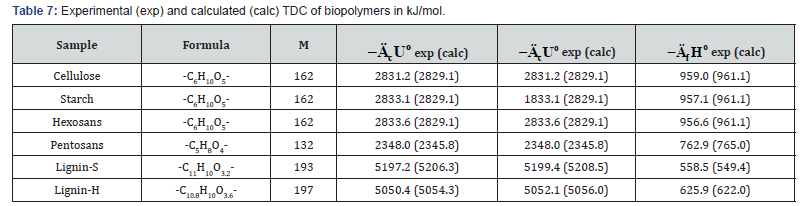

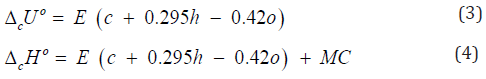

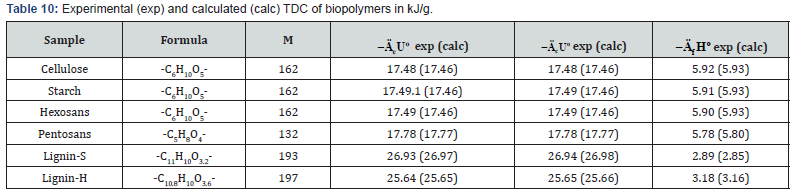

In addition to experimental, there are also quite accurate calculating

methods to determine the TDC of individual biopolymers

of biomass, components of extractives, as well as some plastics

(Tables 7-9). For this purpose, the following equations can be

used [26]:

where E = -413 kJ/mol; c , h and o are number of atoms

C , H and O respectively in molecule of organic substance or in

repeat unit of polymer. ( ( ) 2 2 [ o MC n CO n O RT = −

is correction for

change of moles CO2 and O2 during combustion process, T o = 298

K is standard temperature.

The standard enthalpy of formation was calculated by

equation (2)

In many cases, the TDC are conveniently expressed in kJ/g

(Tables 10-12).

As can be seen from Tables 7-12, the calculated TDC are

quite close to experimentally characteristics determined using

a calorimetric bomb. Thus, the calculation method can be

successfully used for evaluation of TDC of organic components of

biomass, as well as of some plastics.

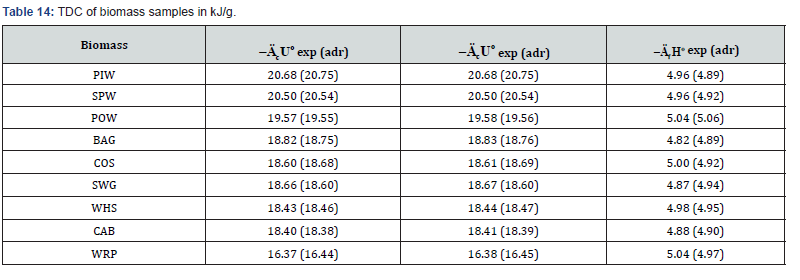

The results of compositional analysis of biomass samples by

standard NREL methods are shown in Table 13.

*Hemi denotes Hemicelluloses; Extr denotes Extractives.

The obtained TDC ( o )

i Y of individual components,

biopolymers and extractives (Tables 10 & 11), and their content

( ) i w in the biomass (Table 13) were used to evaluate the TDC (Y o )

of biomass sample according to additivity rule:

Besides, the pelletized fuels containing of biomass or

composite of biomass and mixed polyolefins (POL) were prepared.

The TDC of these fuels were determined experimentally (exp) or

calculated using the additivity rule (adr). The results revealed that

TDC of solid fuels calculated by equation (5) are confirmed by

experimentally obtained characteristics (Tables 14 & 15). These

data evidence on adequacy of the additivity rule to evaluate the

TDC of biomass-based solid fuels.

The study of pelletized fuels also showed that the densification

of initial biomass does not change the energy and enthalpy of

combustion, but increases the density of thermal energy (ED):

where d is density of solid fuel (kg/m3)

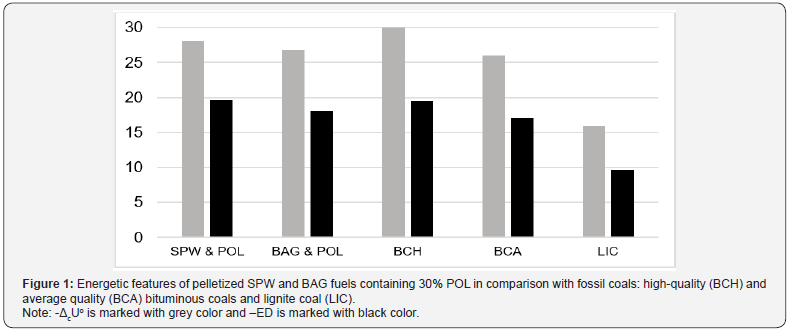

Additive of polyolefins into biomass samples increases the

energy and enthalpy of combustion, as well as the energy density

of the pelletized fuels (Table 15). As a result, energetic features

of biomass-based pellets become comparable with those of fossil

coals (Figure 1).

Figure 1 Energetic features of pelletized SPW and BAG fuels

containing 30% POL in comparison with fossil coals: high-quality

(BCH) and average quality (BCA) bituminous coals and lignite coal

(LIC)

Note: -ΔcUo is marked with grey color and –ED is marked with

black color

Conclusion

Solid fuels made of plant biomass and its compositions

with plastic additive were studied as an alternative to solid

fossil fuels such as coals. For this purpose, experimental and

calculation methods were used to determine the thermodynamic

characteristics (TDC) of individual components of plant biomass

and plastics. Using the results determined for individual

components, the TDC of various biomass samples and biomassplastic

blends were calculated by means of additivity rule. The

results revealed that calculated TDC of solid fuels were close to

experimentally obtained values. Thus, the obtained data evidence

the adequacy of the additivity rule to evaluate the TDC of solid

fuels based on biomass. It has been also found that fuel pellets

consisting of plant biomass and additive of plastics are the most

promising solid fuels, since they provide the higher energy and

enthalpy of combustion, as well as increased density of thermal energy than biomass only. Moreover, energetic features of

pelletized fuels become comparable with those of fossil coals.

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment