Synthesis of Photoactive Ternary Cadmium Sulfoselenide Thin Film via Cost-effective Chemical Technique for Solar Cell Application-Juniper Publishers

JUNIPER

PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

We have successfully developed arrested precipitation technique for synthesis of photoactive Cd(S0.8Se0.2)

thin film. Synthesized thin film were characterized for optical,

structural, morphological and compositional analysis using UV–Vis

spectrophotometer, Xray Diffraction (XRD), Field-Emission Scanning

Electron Microscopy (FESEM) and Energy Dispersive Spectroscopy (EDS)

analyzer techniques. Optical study shows linear nature of plot confirms

direct allowed transition with optical band gap energy 2.13eV. Pure

phase hexagonal nanocrystalline thin film formation confirmed through

XRD pattern. FESEM micrographs indicate construction of void free and

well-adherent twisted nest-like surface morphology containing tremendous

grown flakes over substrate. Presence of Cd2+, S2- and Se2- elements

confirmed by EDS spectrum. Finally, synthesized thin film show power

conversion efficiency of 0.37 %.

Keywords: APT; Nanocrystalline; n-CdSSe; Thin film; Pure phase; η = 0.37%

Abbrevations:

XRD: Xray Diffraction; FESEM: Field-Emission Scanning Electron

Microscopy; CBD: Chemical Bath Deposition; CCGP: Controlled Chemical

Growth Process; APT: Arrested Precipitation Technique

Introduction

In past few years, the world serious energy and

environmental crisis have made more attention to development of new

cost-effective and sustainable energy source [1]. Also, quest for new

alternative renewable energy source is quite argent and necessary.

Overall available technologies photoelectrochemical solar cell

technology has believed to be cost-effective and renewable energy source

for solar energy conversion. Generally, photoelectrochemical

performance of semiconducting materials depends on their respective

properties and essential physiochemical processes in which, i)

Absorption of light radiations, ii) separation of charge carriers, iii)

migration of carriers, iv) recombination of charge carriers and v) redox

reaction. Also, respective properties of semiconducting material are

nothing but, electronic band structure, crystal structure, chemical

constituents and their microstructures.

II-VI group semiconducting compounds are the most

important and highly studied semiconducting material for

scientific and technological point of application due to their direct

band gap [2]. Among this II-VI group semiconducting compounds, typically

CdS and CdSe have 2.40 and 1.70 eV optical band gap with wide

absorption band edge and excellent absorptivity in visible region [2].

These ternary CdSSe thin films synthesized by varied

of method such as, sputtering [3], Chemical Bath Deposition (CBD) method

[4]and solvathermal route [5]. All these methods require highly

sophisticated instruments, harsh experimental condition, different

surface directing agents and solvents [6]. However, in Arrested

Precipitation Technique (APT) their no need to use sophisticated

instrument, different solvents and harsh experimental condition. Taking

into concern these features of technique, we have used APT method for

synthesis of CdSSe thin films. APT method is nothing but hybrid chemical

process of CBD and Controlled Chemical Growth Process (CCGP) [7].

In present investigation, we have successfully deposited

Cd(S0.8Se0.2) thin film using triethanolamine as complexing agent at

via APT method. Our intension is to make efficient photoelectrode

for photoelectrochemical application using triethanolamine as

surface directing agent. Synthesized thin film show 0.37% power

conversion efficiency under illumination of 500W tungsten

filament lamp (intensity 30mW cm-2). Also, thin film formation

growth process by using APT is discussed detailed.

Experimental

Chemicals

All chemicals were of analytical reagent (AR) grade and

used without further purification. Cadmium sulfate hydrate

(CdSO4.H2O) (98%, S-D Fine Chem.), thiourea (H2N-CS-NH2)

(99%, S-D Fine Chem.) selenium metal powder (99.5%, Sigma

Aldrich), sodium sulfite (Na2SO3) (96%, S-D Fine Chem.), liquor

ammonia (NH3) (28-30% Thomas Baker), and triethanolamine

(N(CH2CH2OH)3) (99%, Merck).

Synthesis of Cd(S0.8Se0.2) thin film

In typical synthesis, initially Cd-TEA complex was prepared by

triturating ‘Cd’ with TEA as complexing agent for 6 h homogenous

crushing to form clear Cd-TEA complex. All metal ions and

chalcogen ions precursors’ concentration is optimized at initial

stage of synthesis as 0.05M. Cd-TEA complex release Cd2+ metal

ions slowly and react with S2- and Se2- chalcogen ions released from

dissociation of H2N-CS-NH2and Na2SeSO3 at alkaline pH, 10.4, and

50±2 °C bath temperature at 2.30h deposition time. Formation of

thin films is well dependant on various preparative parameters

such as, deposition time, bath temperature, pH and precursor

concentration. These parameters were optimized during initial

stage of thin film synthesis.

After desired deposition time deposited film was removed

from bath and washed with double distilled water and dried at

room temperature in air. Deposited film was yellowish red in

colour and designated as Cd(S0.8Se0.2).

Characterization of thin film

Thickness of film was measured using surface profiler

(AMBIOS XP-1). Optical absorption spectra were taken by using

a UV-Vis-NIR spectrophotometer (Shimadzu, UV-1800). Structural

properties and crystallite size were carried out using an X-ray

diffractometer (Bruker AXS, D8) using Cu Ka (l= 1.5418 Å). Surface

morphology and the elemental composition of the as-deposited

thin films were characterized using field-emission scanning

electron microscopy (FESEM) equipped with an energy dispersive

X-ray spectroscopy (EDS) analyzer (Hitachi, S-4700). PEC

measurements were carried out using a semiconductor parameter

analyzer (Keithley SCS-4200 Semiconductor) characterization

unit using 500 W tungsten filament lamp (intensity 30mW cm-2)

with sulfide/polysulfide electrolyte.

Results and Discussion

Formation Growth mechanism

Main principle behind the film formation is slow ion-byion

condensation of ions followed by multi nucleation process.

Precipitation of metal chalcogenide thin films is occurred when

ionic products (Kp) of Cd2+, S2- and Se2- ions exceed solubility

product (Ksp) of Cd(SSe) in films. Slow release of metal and

chalcogen ions from respective complex results into highquality

and well-adherent thin films formation [7-9].

Optical absorption studies

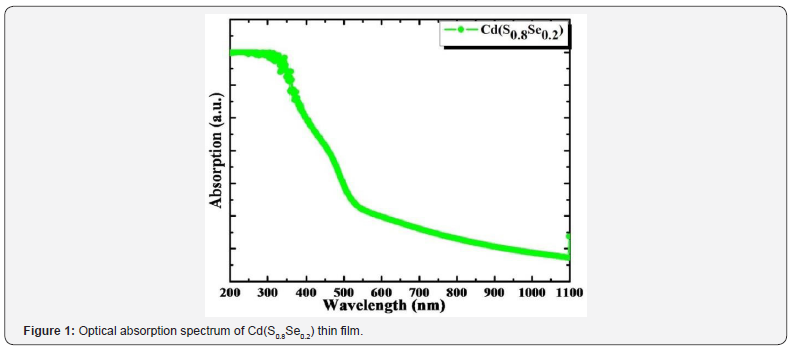

Figure 1 shows optical absorption spectrum of Cd(S0.8Se0.2)

thin film recorded using UV-VisNIR spectrophotometer in 200-

1100nm wavelength range. Maximum light absorption edge

observed at 650nm. Fundamental absorption corresponds to

electron excitation from valance band to conduction band, used

to determine value of optical band gap energy. Optical data were

demonstrated using following eq. (1) as follows,

where, A is a parameter that depends on the transition

probability, h is Planck constant, Eg is optical band gap energy

of material, and exponent depends on the type of transition.

The values of n for direct allowed, indirect allowed, direct

forbidden and indirect forbidden transitions are 1/2, 2, 3/2 and

3, respectively (Figure 1).

From optical absorption spectrum clearly demonstrated

that linear nature of plot confirms direct allowed type transition

mechanism.

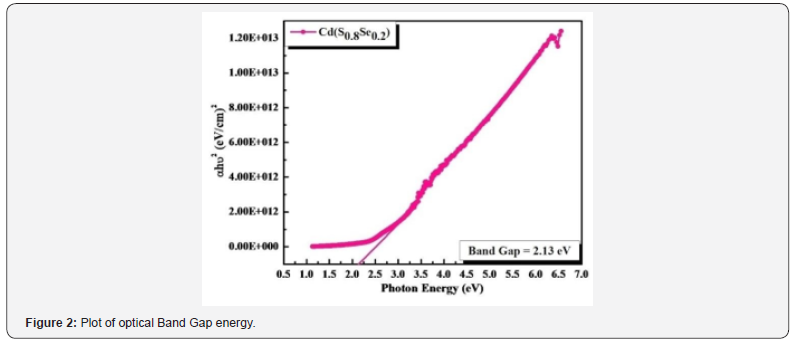

Figure 2 shows plot of (ahϑ)2 vs photon energy (hϑ), value

of optical band gap was calculated by extrapolating straight-line

portion to X-axis. Obtained optical band gap energy is 2.13 eV,

which is consistent with other reported ternary CdSSe thin films

[7]. 3.3. X-ray diffraction study

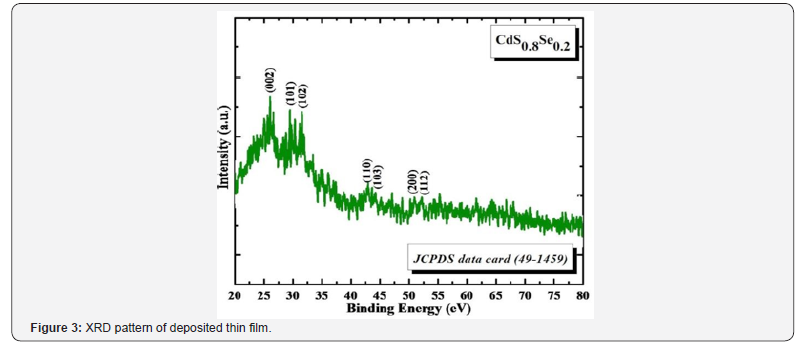

Figure 3 indicates typical X-ray diffraction pattern of

Cd(S0.8Se0.2) thin film deposited by using APT method. All

diffraction peaks are corresponding to (002), (101), (102),

(110), (103), (200) and (112) at 2θ 26.02º, 28.40º, 31.13º,

42.80º, 44.93º, 50.89º and 52.07º of hexagonal crystal structure.

Calculated d-values are in well-agreement with standard d-values

(JCPDS card no. 49-1459) for an (hkl) plane, confirms formation

of thin films with a pure phase material.

Crystallite size is calculated by using known Scherrer formula

and calculated crystallite size is 55nm. Thickness of thin film is

728nm measured by using surface profiler analysis. Crystalline

nature and phase pure formed thin films are highly favorable for

enhanced light absorption in solar cell application [8].

Field emission scanning electron microscopy

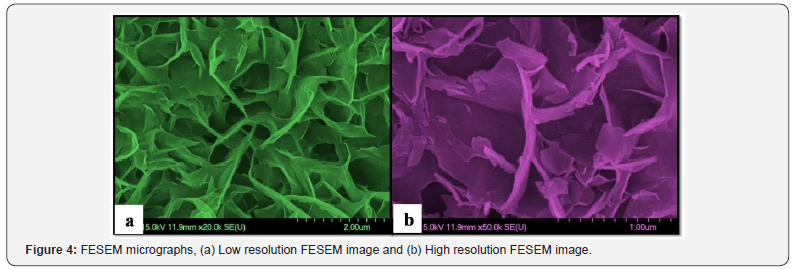

Surface morphology of thin films carried out by using FESEM

study. Figure 4 demonstrates FESEM micrographs at different

resolution of Cd(S0.8Se0.2) thin film. Low resolution FESEM

image of Figure 4 (a) point out void free and well adherent film

formation occurs via APT method. It shows twisted nest-like

surface morphology is observed overall substrate surface.

High resolution FESEM images of Figure 4(b) clearly illustrate

that twisting of nest-like morphology with irregularly grown

sharp edged flakes. Such huge number of flakes winds together

and formation of large network of nest-like morphology is

observed from high resolution micrograph. This obtained surface

morphology is beneficial for improve light absorption potential

may due to crystalline nature and large surface area of nest-like

morphology with twisted flakes [9].

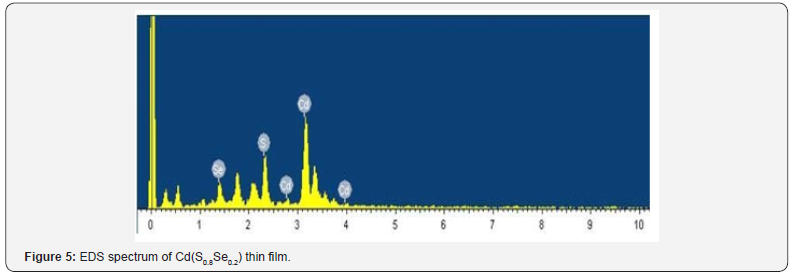

Energy dispersive spectroscopy

Quantitative analysis of element is confirmed through EDS

study. Figure 5 shows typical EDS spectrum of deposited thin film.

EDS spectrum shows peaks at 3.13, 2.50 and 1.38 keV confirm the

presence of Cd, S and Se elements respectively [7].

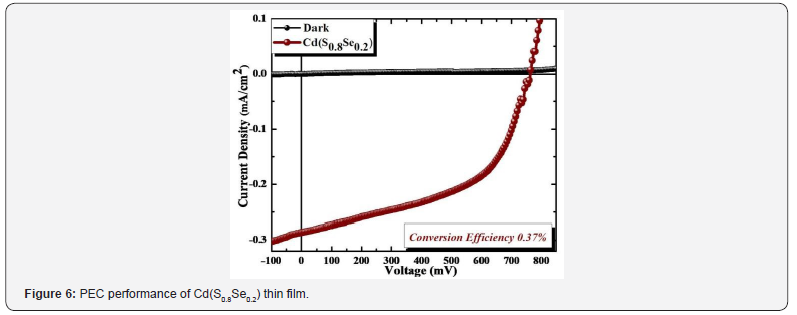

Photoelectrochemical performance

PEC performance of Cd(S0.8Se0.2) thin film was measured with

standard two-electrode system. Figure 6 shows J-V curve of PEC

cells. PEC performance was measured by forming Cd(S0.8Se0.2) thin

film as working photoelectrode with active area 1cm2 and graphite

rod (G) as counter electrode in 0.5M sulfide/polysulfide redox

electrolyte. J-V measurements were done under illumination of

light using 500 W tungsten filament lamp (Intensity of 30mW/

cm2). In dark, J-V curve shows diode-like rectifying characteristics.

Upon illumination, curve is obtained at fourth quadrant, indicating

generation of electricity and n-type conductivity nature [6-7].

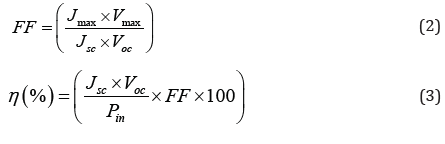

Fill factor (FF) and power conversion efficiency (η %) of thin

film were calculated by using equations (2) and (3) as follows,

where, Jmax and Vmax are maximum short-circuit current density

and maximum open circuit voltage, Pin is input light intensity

(30mW/cm2). Jsc is short-circuit current density and Voc is open

circuit voltage. From J-V measurement, short circuit current density

(Jsc) is 0.288mA cm-2 and that of open circuit voltage (Voc) 765mV.

Calculated power conversion efficiency is 0.37% for Cd(S0.8Se0.2)

thin film. Overall obtained conversion efficiency might be due to

good crystallinity and developed surface morphology with large

surface area [9]. Table 1 shows calculated PEC parameter.

Conclusion

Developed facile, cost-effective APT method shows potential

for synthesis of thin films for solar cell. Synthesized thin film

show promising properties favorable for photoelectrochemical

performance is investigated. Optical study showed light absorption

in visible region of solar spectrum and direct allowed transition

mechanism. From XRD pattern it confirmed that formation of

pure phase hexagonal crystal structure with nanocrystalline

nature. FESEM analysis demonstrated synthesized surface

morphology is void free and having large surface area for efficient

light absorption. EDS pattern confirmed presence of Cd2+, S2- and

Se2- elements in synthesized thin film. PEC performance indicated

conversion efficiency of 0.37%.

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment