Polyurethane Acrylate/Montmorillonite Nanocomposites-Juniper Publishers

JUNIPER PUBLISHERS- ACADEMIC JOURNAL OF POLYMER

SCIENCE

Abstract

In order to create polymer nanocomposites with high

performance on the basis of polyurethane acrylates (PUA) with

montmorillonite (MMT), three methods of chemical modification of the

layered silicate surface have been developed. The first modification

method is based on using of two different functional modifiers

(organophilic and reactive), the second method is based on modification

with synthesized by us compound which contains urethane groups, and the

third one in based on using synthesized by us modifier containing

urethane and reactive groups. Exchange capacity of the MMT surface was

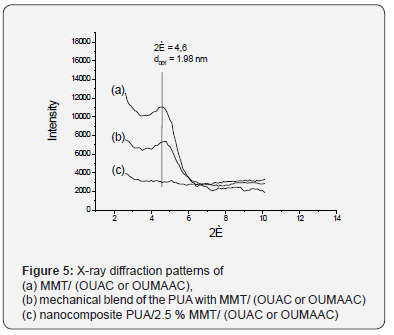

determined by adsorption of indicator “methylene blue”. Intercalation of

modifier into the interlayer space of MMT was confirmed by X-ray

analysis; the content of organic component in the modified MMT (MMT/M)

was determined by thermogravimetric analysis. The resulting organoclay

is purposed for the formation of nanostructured composites based on

cross-linked polyurethane acrylates with improved physical and

mechanical properties. The obtained polyurethane acrylate nanocomposites

with different type MMT/M exhibit the increased in 1.6 - 2.6 times

tensile strength as compared to original polymer matrix. WAXS method has

proved an intercalation of modifier into MMT interlayer space

(increased distance between layers after modification), as well as the

total exfoliation of MMT in PUA matrix, characterized by the

disappearance of the absorption peak which is responsible for layered

structure.

Keywords: Montmorillonite; Modification; Polyurethane acrylate; Nanocomposites

Abbrevations:

CTAB: Cetylammonium Bromide; DMF: Dimethyl Formamide; DMAEMAC:

Dimethyl Ammonium Ethyl Methacrylate Chloride; DTA: Differential

Thermogravimetric Analysis; HMDI: 1,6-Hexamethylene Diisocyanate; OUA:

Oligourethane Acrylate; OUAC: Oligouretane Amonium Chloride; OUMAAC:

Oligourethane Methacrylate Ammonium Chloride; POTMG-1000: Poly Oxytetra

Methylene Glycol with Molecular Weight of 1000; NMDEA: N-Methyldiethanol

Amine, Na-MMT; Na-form of Montmorillonite; MB: Methylene Blue; MDI - 4:

4´- Diphenylmethane Diisocyanate; MW: Molecular Weight; MWD: Molecular

Weight Distribution; MMT: Montmorillonite; MMT/M: Modified

Montmorillonite; PP: Prepolymer; PUA: Polyurethane Acrylates; WAXS:

Wide-Angle X-ray Scattering

Introduction

Lately polymer-based nanocomposites are of great

interest both in science and industry due significant improvement of

performance of their properties compared to initial polymers and

conventional macrocomposites. Polymer based nanocomposites are

characterized by increased strength and heat resistance as well as

reduction of gas permeability and flammability [1]. Creation of

polyurethane acrylate (PUA) - organoclay based nanocomposites with high

performance properties is a real chance to improve the basic properties

of initial PUA polymer matrix. The increase of the strength and

durability of PUA based materials may be achieved by incorporation of

organoclay nanoparticles into the polymer matrix [2]. In order to modify

the natural MMT by ion exchange method, it should be converted to the

sodium (rarely to potassium) form by treatment with alkali metals

carbonates [3], since the alkali metal cations are easier replaced on

the organic cations compared to alkaline-earth cations of natural MMT.

In order to create polymer based on There are the following ways of MMT

modification used in

the field of polymer nanocomposites based on polar heterochain polymers:

a) modification with cationic surfactants (ammonium and phosphonium cations) [4].

b) modification with reactive compounds [2,5].

c) modification with monomers during the reaction of

polycondensation followed by the chain growth in the interlayer space

[1,6].

A disadvantage of the first method is nonpolar

nature of the used surfactants. As a result of different nature of the

organic modifier and polymer matrix the particles of modified MMT form

an agglomerate that do not contribute to the intercalation and

exfoliation of polyurethane into the interplanar space of MMT.

Disadvantages of the second method are a small molecular size of

reactive modifiers’ molecules which does not provide a sufficient

organophilicity of the mineral surface that complicates the penetration

of the monomer molecules into the interplanar space. The same drawbacks

are observed in case of the third

modification method, namely modification with diamines, one

of the amino groups of which is in a salt form and it is capable

to ion exchange reactions in interplanar space of MMT. The sizes

of the molecules of these monomers are not large enough to

provide the sufficient organophilicity of MMT to overcome the

agglomeration of the particles.

In order to create polymer nanocomposites with high

performance on the basis of polyurethane acrylates (PUA) with

montmorillonite (MMT), three methods of chemical modification

of the layered silicate surface have been developed. The first

modification method is based on combined modifying of MMT

with two types of modifiers: cationic surfactant (cetylammonium

bromide), which imparts organophilicity to MMT surface and

facilitates dispersion of the mineral in organic medium; and a

bifunctional amine - dimethylaminoethyl methacrylate. The

developed method of MMT functionalization alows to obtain

an organophilisized minerals containing reactive groups of

different nature (acrylate, hydroxy, amine) on its surface, capable

to participate in reactions of photoinitiated polymerization and

polycondensation [7], which should increase the physical and

mechanical properties of polymers. The second method of MMT

modification lies in use of ammonium ions as surfactants, which

include the urethane groups - oligouretane ammonium chloride

(OUAC). Its molecule is sufficiently sterically large for provide

the intercalation and exfoliation of MMT particles in polar

organic media [8,9]. The new approach of MMT modification

in contrast to the classical use of surfactants composed of ionic

group and aliphatic large fragment (C12 - C20), consists in the

use of synthesized by us surfactants with urethane groups in

their structure. MMT modified with such cationic surfactants can

form stable hydrogen bonds with polymer matrix: polyurethane,

polyamide, polyamide, etc. Hydrogen bonding between the

modified surface of MMT and polyurethane macromolecules

provides a complete exfoliation of the modified MMT particles

and strong physical interaction between inorganic and organic

components. The high affinity of the modified nanofillers with

polymer matrix provides the increased strength of polyurethane

and other polar polymers-based materials. The third method.

In order to create the nanofiller which form both physical

and chemical bonds with polymer matrix, the new modifier

oligouretane methacrylate ammonium chloride (OUMAAC)

having both urethane and reactive methacrylate groups was

synthesized [10,11]. The new modifier was synthesized by

analogy with above mentioned OUAC.

Reactive methacrylate groups form chemical bonds with

oligourethane acrylate matrix during the in situ polymerization.

Modified surface of MMT nanoparticles, exfoliated due to the

presence of urethane groups, provides not only physical but also

chemical affinity with polymer matrix. Physical and chemical

bonds of nanofiller with polyurethane acrylate matrix provides

a significant increase of polymer nanocomposite service

properties as compared to the initial polymer matrix.

Materials and Methods

We used a natural montmorillonite from clay deposit

“Askaniya” (Georgia). MMT modifiers: cetylammonium bromide

(CTAB) [Aldrich] and dimethylammoniumethylmethacrylate

chloride (DMAEMAC) [Aldrich]. N-methyldiethanol amine

(NMDEA) [Aldrich]; 1,6-hexamethylene diisocyanate (HMDI)

[Aldrich] were used for synthesis of oligouretanamonium

chloride (OUAC) nanomodifier. Isopropyl alcohol was distilled

in the presence of anhydrous calcium chloride and fraction

with bp = 82oC was isolated. For the synthesis of OUMAAC

nanomodifier, the N-methyldiethanol amine (N-MDEA)

[Aldrich], 1,6-hexamethylene diisocyanate (HMDI) [Aldrich],

hydroxyethyl methacrylate (HEМА) [Aldrich] were used.

Polyoxytetramethylene glycol with molecular weight of

1000 (POTMG-1000) [Aldrich], 4, 4´- diphenylmethane

diisocyanate (MDI) and HEМА [Aldrich] were used for synthesis

of polyurethane acrylate (PUA). 2- propylolphenyl keton

(Darokur-1173) was used as a photoinitiator of polymerization.

To determine the exchange capacity of MMT the indicator of

methylene blue (MB) (ZAT “Khimservice”, Russia) was used.

Preparation of the sodium form of MMT

The suspension of original MMT (5%) in distilled water

boiled for 1 hour with sodium carbonate in a weight ratio of

MMT: sodium carbonate = 100:1 was used for obtaining of Naform

of MMT (Na-MMT). The fourfold centrifugation, followed by

washing with distilled water, was used to separate the resulting

Na-MMT from the solution of sodium carbonate. The content of

dry matter in Na-MMT suspension was defined gravimetrically.

Modified MMT/M was then obtained using the resulting Na-

MMT suspension.

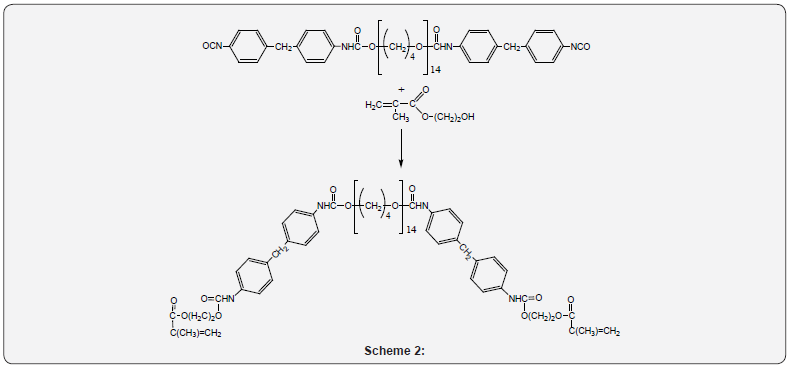

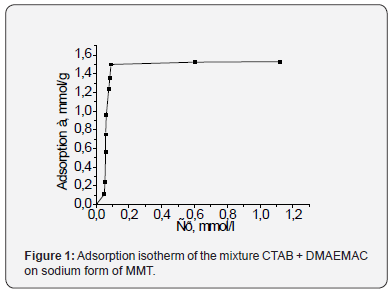

Exchange capacity of Na-MMT

Exchange capacity of the MMT surface was determined

by adsorption of indicator “methylene blue” onto Na-MMT

surface using photocalorimetry analysis [12] for calculation

the modifier: MMT ratio. To determine the exchange capacity of

MMT the estimation of adsorption of MB on the MMT surface

was carried out, i.e. the dependence of the adsorption value on

equilibrium MB concentration (the concentration of the solution

on reaching the adsorption equilibrium). For that the eight

samples of MMT with the same mass were filled up with the

solutions of the same volume but different concentrations of MB.

The equilibrium concentration was determined in three days.

The adsorption (α, mmol/g) was calculated as the difference

between the initial amount of MB added to MMT suspension in

solution with concentration C0 and the amount of MB remaining

after adsorption onto 1g of montmorillonite according to:

where: C0 - initial concentration of MB;

Cp - equilibrium concentration of MB (per 1 g of MMT) after

adsorption;

V - volume of an aqueous sample solution, l;

g - mass of the MMT sample.

The equilibrium concentration increases sharply after

adsorption raises more than 1.5mmol/g. That mean that exchange

capacity of MMT used amounts to 1.5 [13]. The concentration of

MB in solution was measured by photocolorimeter CK-2PM (PO

“ZOMZ”, Russia) after the separation of aqueous solution from

the MMT.

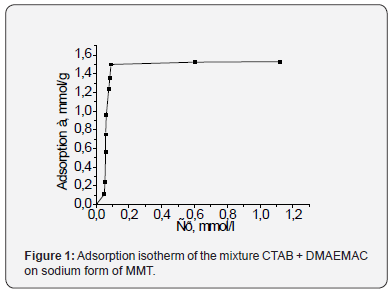

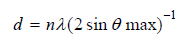

X-ray diffraction

The polymer structure in the molecular level was studied

by the wide-angle X-ray scattering technique (WAXS) using a

DRON-4-07 diffractometer; X-ray optic scheme was arranged

to operate in the transmission mode of the Debye-Scherrer

method. CuK α-radiation used as produced by an anode X-ray

generator was monochromatized with a Ni-filter. The details of

WAXS are presented in [14]. Scattered X-rays were detected with

a scintillation counter in an automated stepwise scanning mode.

The measured values of scattering intensity were corrected

for attenuation of the incident X-ray beam by tested samples

and subsequent deviation of the intensity of background X-ray

scattering by the collimator system. The values of scattered

intensity were normalized to the scattering volume. Finedispersed

powders of ММT and MMT/M were placed into the

cells. Registration of scattered intensity was carried out under

condition of step-type scanning of scintillation detector in the

scattering angles range from 2 to 400. The distance (d) between

layers of particles in the MMT was determined from Bragg’s

equation [15]:

where n - the serial number of the diffraction peak in the

diffraction patterns (n = 1), λ - wavelength of the characteristic

X-rays (for CuKα λ = 0,154nm), θ - angle of X-ray scattering.

IR-spectroscopy

Samples of modifier were obtained on irtran substrate by

pouring from an aqueous solution. FTIR spectra were measured

using infrared Fourier transform spectrometer «Tensor-37»

Bruker / FT-IR-Spectrometer (Germany) in the range of wave

numbers of 4500-500cm-1. The assignment of the bands was

performed according to [16].

Mechanical testing

The tensile device FU-1000 (VEB MWK “Fritz Heckert”,

Germany) was used. The tensile speed was 100mm min-1

and temperatue 25 0C. For each measurement we used three

samples. Samples were prepared in a form of strips (width - 4

mm, operating length - 2mm). Measurements were carried out in

accordance with Standard 14236-81; allowed error - 3%.

Differential thermogravimetric analysis

Differential thermogravimetric analysis (DTA) was carried

out using a Q-1000 derivatograph, (MOM, Budapest) in the air

under the following conditions: average heating rate -10 deg

min-1; temperature range: 20-10000C; the weight of samples:

100mg; inert substance: Al2O3; sample holder: a ceramic conelike

crucible.

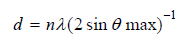

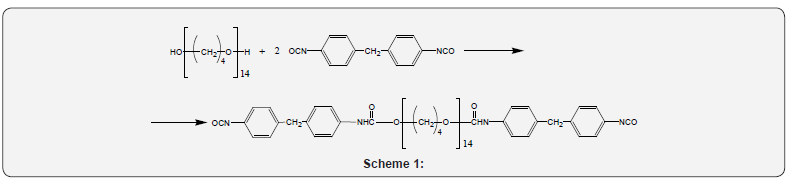

Prepolymer synthesis

In order to obtain the prepolymer (PP) the initial components

were placed into a three-necked reactor, equipped with inputoutput

device of inert gas (argon) in amount corresponding to

the ratio of their functional groups - NCO:OH = 2:1. The resulting

mixture was heated under the continuous stirring at 80 - 850C

(30min), followed by cooling the reacting mixture to 150C. The

estimated content of isocyanate groups in the PP amounted

to 6.3 ± 0.1 %wt. Scheme of PP synthesis is presented below:

(Scheme 1)

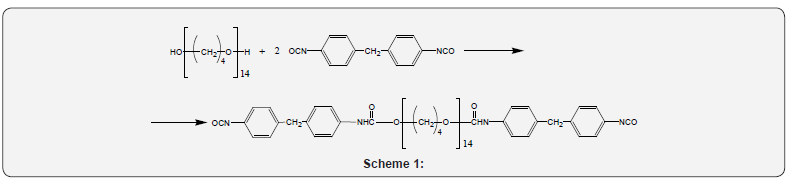

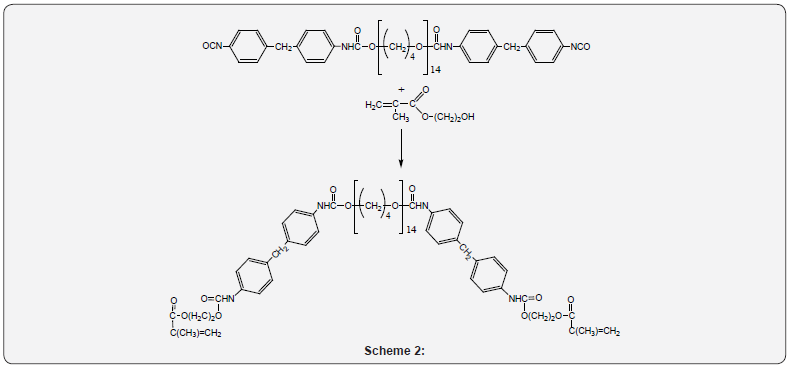

Synthesis of oligourethane acrylate (OUA)

OUA was synthesized using MDI based PP. The calculated

amount of HEMA in dimethyl formamide (DMF) was added to

PP at the temperature of 55 0C under continuous stirring; the

NCO:OH ratio = 1:1. The process of OUA formation took no more

than 1h under the continuous stirring at 55 0С.

Scheme of OUA preparation: (Scheme 2)

Results and Discussion

Modification of Na-MMT with different types of modifiers

The joint adsorption of components was studied using the

method of two-phase titration with sodium lauryl sulfate in

the presence of indicator MB, which was used for the selective

determination of the concentration of the surfactant CTAB [12],

which allows to determine the content of CTAB - the only one

cationic component, which is a classical surfactant.

In order to study the joint adsorption, the weighted amount

of Na-MMT suspension was mixed with solutions of CTAB and

DMAEMAC (with different ratio of the latter). The amount of

CTAB and DMAEMAC was equivalent to exchange capacity of

MMT (1.5mmol/g). To determine the equilibrium concentration

of CTAB, the titration of the solution was carried out after

attaining of adsorption equilibrium (in three days).

Two-phase titration of solutions after attaining of adsorption

equilibrium showed that CTAB adsorbed on the Na-MMT

regardless of DMAEMAC content in solution in an amount which

corresponds to the exchange capacity of MMT (1.5mmol/g).

Adsorption isotherms of CTAB mixed with DMAEMAC have the

same character as in the absence of the latter (Figure 1).

Thus, it has been found experimentally that CTAB as strong

cationic surfactant capable to displace the DMAEMA ions from

the montmorillonite surface. Therefore, modification with CTAB

was carried out in an amount that corresponds to half of the

ion exchange capacity of the mineral, and DMAEMAC addend

was carried out with 30% excess per the residual ion exchange

capacity, which was 50% of the initial ion exchange capacity of

the mineral. To prove the simultaneous co-adsorption of both

CTAB and DMAEMAC on the Na-MMT it was necessary to find

a way of detection of DMAEMAC ions in aqueous solution. For

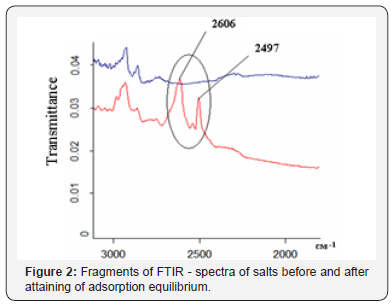

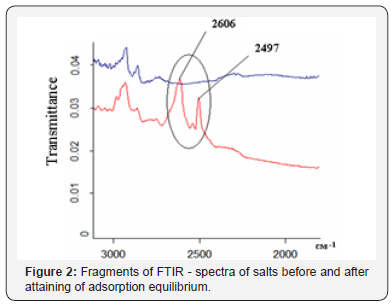

this purpose, we used FTIR spectroscopy. Based on the fact that

determination of the low concentrations of DMAEMAC using

FTIR spectroscopy is not possible, we decided to analyze the dry

residues of salts’ aqueous solutions on irtran. FTIR data have

shown, that dry residues of DMAEMAC solutions have a visible

absorption band with maximum at 2497cm-1 and 2532cm-1 [16],

corresponding to NH+ of alkylammonium. Therefore, to prove

the joint adsorption the weight amount of Na-MMT suspension

was poured with a solution of CTAB and CTAB DMAEMAC in the

ratio: CTAB - 0.75mmol/g MMT and DMAEMAC - 0.75mmol/g

MMT, respectively. Preliminary we obtained the FTIR spectrum

of dry residue of DMAEMAC solution which was added to MMT.

It can be clearly seen the absorption bands with maxima at

2497cm-1 and 2532cm-1 (Figure 2). After attaining of adsorption

equilibrium (in three days) the FTIR spectrum of the dry residue

of the solution displayed a complete absence of absorption bands that corresponded DMAEMAC. Thus, the adsorption

of DMAEMAC was confirmed by comparative analysis of the

FTIR spectra of salt solutions “before” and “after” attaining of

adsorption equilibrium (Figure 2).

Absorption band with the maximum at 2606cm-1 in the FTIR

spectra (Figure 2) of dry residues of initial solution of amine salts

indicates the presence of NH+ of alkyl ammonium cation (bands

at 2497cm-1 and 2532cm-1) whereas in sample after installing

the adsorption equilibrium these bands are not found. MMT

modification was carried out by adding the modifier solutions

(CTAB and DMAEMAC) of preset concentration to aqueous Na-

MMT dispersion. After adding CTAB and DMAEMAC solutions the

resulting mixture was diluted with distilled water to a ratio of 1g

MMT per 500ml of water. Modification was carried out for 48

hours, whereupon the precipitate of modified MMT was filtered,

dried in an oven at 60 °C till constant weight and crushed in an

agate mortar and in a ball mill. The content of organic component

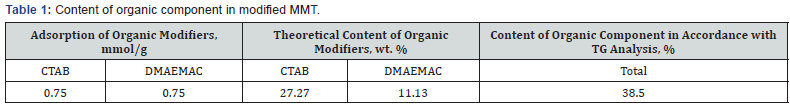

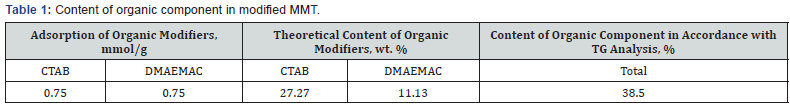

in modified montmorillonite was evaluated using TG data, (Table

1) as the difference between the mass of the sample “before”

and “after” thermo destruction with regard to moisture content

(0.5%wt.). The content of organic component in the modified

montmorillonite - amounts to 0.75mmol/g for each of the two

components and corresponds to the value of exchange capacity

of montmorillonite surface.

Modification of Na-MMT with oligouretane ammonium chloride (OUAC)

Based on the fact that chemical modification of MMT is

carried out predominantly with aqueous solutions of cationic

surfactants with a concentration below the critical micelle

concentration, we have proposed a scheme for the obtaining

of cationic surfactant (OUAC) solution, with a concentration

of 4x10-3 mol/l. OUAC synthesis was described in previous

publication [13]. The structural formula of OUAC: (Scheme 3)

n=1-3

Modification of MMT was carried out by addition to Na-MMT

suspension of the solution of OUAC with 50% excess relative to

calculated exchange capacity of Na-MMT. After adding an OUAC

solution the resulting mixture was diluted with distilled water to

a ratio of 1g MMT per 500ml of water. Addition of OUAC solution

to the MMT suspension resulted in instantaneous coagulation

of MMT particles followed by formation of a white precipitate.

Filtration, drying and grinding of the modified MMT was carried

out by analogy with the previous method. To assess the content

of the organic component in the modified MMT, the TGA study

was conducted. TGA data showed that the organic part content

was about 40% that substantially corresponds to its theoretical

content.

Swelling of modified MMT in organic solvents

Swelling study of modified MMT in organic solutions showed

that the modified MMT formed a stable gel in aprotic organic

solvents such as dimethyl formamide and dimethyl sulfoxide. Gel

formation indicates a high degree of solvent intercalation into

the interlayer space of MMT and physical network formation.

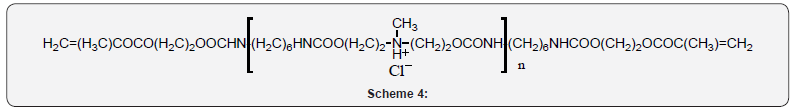

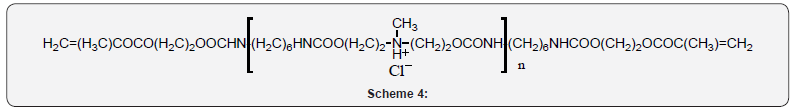

Modification of Na-MMT with oligouretane methacrylate amonium chloride (OUMAAC)

Preparation of cationic surfactant OUMAAC solution with a

concentration of 5x10-3mol/l was carried out similarly to OUAC.

OUMAAC Synthesis was described in previous publication [17].

The MMT OUMAAC modification was carried out similarly to the

OUAC modification. The structural formula of OUAC: (Scheme 4)

n=1-3

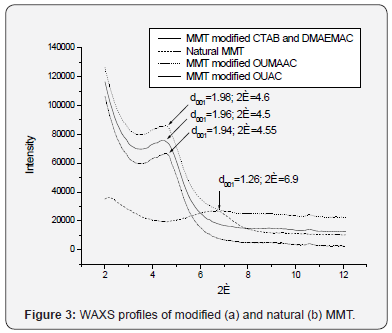

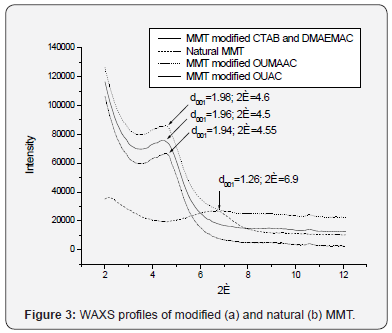

X-ray study of natural and modified MMT

WAXS results (Figure 3) has shown, that modified MMT has

a larger interlayer spacing d001 in comparison with the original

natural MMT (d001 = 1.26nm).

The distance between the MMT layers after modification

increases up to 0.68 - 72nm. It should be noted that the “unification” of inorganic cations in the middle of the layers

in case of Na-MMT reduces the interlayer distance d001 till

1.15nm. Thus, the effect of increasing of the interlayer distance

of MMT as a result of modification with organic compound can

be estimated as 0.79 - 0.83nm.

The increase in the interlayer distance of MMT (d001) after

the modification testifies to intercalation of organic modifier

into the interlayer space.

Preparation of nanocomposites based on PUA and modified ММТ

Formation of nanocomposites based on PUA and modified

MMT was carried out in a solution of organic solvent. In the case

of MMT, modified jointly with CTAB and DMAEMAC we used

toluene, in a case of MMT, modified with OUAC and OUMAAC we

us dimethylformamide (DMF).

PUA and MMT/M based nanocomposites were prepared in

toluene/DMF solution. Solution of toluene/DMF with calculated

amount of OUA and modified MTT was sonicated in a glass

container, then added to the reactor and stirred at 90 0C for five

hours. Then the photoiniciator Darokur-1173 in the amount of

2.5% per OUA weight was added to the reaction mixture which

was stirring for one hour. After stirring the resulting mixture in

toluene/DMF solution was poured from the reactor into a conical

flask with a stopper wherein the resulting mixture was settled.

Settled mixture was cast on glass Petri plates in equal

portions to produce the films of uniform thickness. The films

were formed by the gradual evaporation of the solvent under

normal conditions. The resulting films were irradiated with a UVlamp

for 30min at irradiation intensity of 8W/m2. Conversion of

methacrylate groups was determined by IR spectra: in 20min.

the band corresponding to methacrylate groups has disappeared.

Thus, by photoinitiated polymerization of OUA the films of

polymer matrix PUA and in situ nanocomposites PUA/MMT/M

with the content of modified mineral of 2.5wt% have been

obtained.

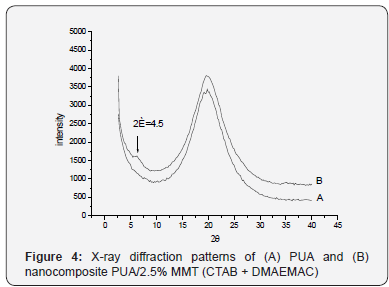

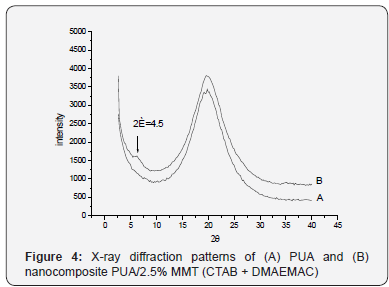

WAXS patterns of PUA/ММТ/M nanocomposite

It was found by WAXS method that exfoliation of nanofiller

in MMT modified with CTAB + DMAEMAC based nanocomposite

was not observed. Lack of exfoliation is illustrated by the

presence of absorption peak characteristic for the modified

MMT on the curve corresponding to the nanocomposite (Figure

4).

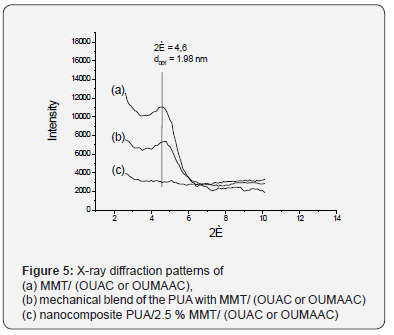

Unlike the first type of nanocomposite, the complete

exfoliation of the nanofiller was observed for nanocomposites

based on MMT modified with OUAC or OUMAAC. The absence

of the characteristic absorption peak of the MMT/ (OUAC

or OUMAAC) in nanocomposites’ WAXS patterns (Figure 5)

containing 2.5wt% of the nanofiller, testifies to the it complete

and systematic exfoliation in the PUA matrix. The absorption

peak 2Θ = 4.6 in the diffraction pattern of mechanical mixture

(b) is characteristic for the MMT/M, indicating that polymer

matrix by itself does not affect the character of MMT (OUAC or

OUMAAC) radiation absorption.

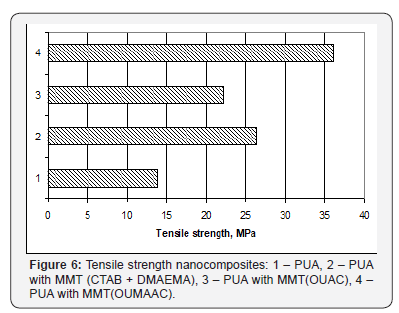

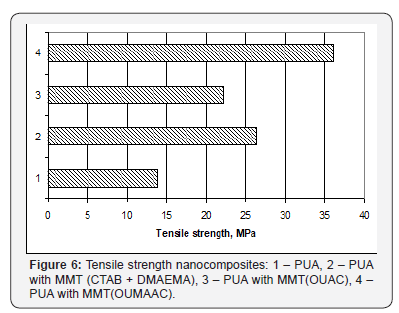

Physic-mechanical properties nanocomposites

Comparative analysis of the tensile strength of all obtained

nanocomposites with the same content of modified MTT

(2.5wt%) has shown a significant increase of tensile strength

relative to the original polymer matrix PUA (Figure 6).

It was found that nanocomposite with MMT (CTAB +

DMAEMA) has in 1.9 times higher strength than that of the

original PUA matrix. Increase of the strength of nanocomposite

with MMT (CTAB + DMAEMAC) may be the result of chemical

bonds formation between PUA and DMAEMAC on the MMT

surface.

Nanocomposite with MMT (OUAC) and nanocomposite with

MMT (OUMAAC) possess the strength in 1.6 and 2.6 times higher

than that of the original PUA matrix, correspondingly. Such

difference in the results is probably due to the fact that MMT

(OUAC) cannot form chemical bonds with PUA matrix.

Comparative analysis of the strength indices of all obtained

nanocomposites has clearly illustrated the strengthening effect

of reactive modifiers DMAEMAC and OUMAAC.

Nanocomposite with MMT (OUAC), despite the exfoliation

of nanofiller and the formation of hydrogen bonds with PUA

macromolecules, is inferior to nanocomposite with MMT (CTAB

+ DMAEMAC) for which the exfoliation of the nanofiller is not

typical.

Conclusion

Three methods of chemical modification of the layered

silicate surface have been developed.

a) New polyurethane acrylate nanocomposites based on

newly created modified MMTs with high performance have been

synthesized by in situ polymerization method.

b) The first modification method is based on using of

two different functional modifiers (organophilic and reactive),

the second method is based on modification with synthesized

by us compound which contains urethane groups, and the third

one in based on using of synthesized by us modifier containing

urethane and other reactive groups.

c) Developed polyurethane acrylate/organoclay

nanocomposites have shown a significant increase of strength

indices.

d) The complete exfoliation of the nanofiller in

nanocomposite based on MMT modified with OUAC or OUMAAC

has been confirmed by WAXS.

Developed methods of montmorillonite modification

are universal and can be applied to MMT of various origins

(deposits).

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment