Polymer-Based Approach in Ceramic Materials Processing for Energy Device Applications-Juniper Publishers

JUNIPER

PUBLISHERS- Academic Journal of Polymer Science

Abstract

Polymer-based approach such as sol-gel method is a

well-known method to produce ceramics materials with excellent

properties for a better performance of solid oxide fuel cell. The

properties of the materials are generally controlled by chemical agents

used in this method. The roles of the chemical agents including

chelating agent, polymerization or esterification agent and surfactant

are presented and briefly discussed in this mini review paper.

Keywords: Sol-gel method; Polymerization agent; Surfactant; Electrolyte; Anode; Cathode; Solid oxide fuel cell; MicrostructureAbbrevations:SOFCs: Solid Oxide Fuel Cells; SSR: Solid-State Reaction; WCMs: Wet Chemical Methods; CA: Citric Acid; EDTA: Ethylene Diamine Tetra-Acetic Acid; EG: Ethylene Glycol; TETA: Triethylenetetramine; PEG: Poly-Ethylene Glycol; PVA: Polyvinyl Alcohol; PVP: Polyvinyl Pyrrolidone; YSZ: Yttria-Stabilized Zirconia; AC: Activated Carbon

Introduction

High temperature perovskite-type oxide conductive

ceramics have attracted great attention worldwide due to the fact that

these materials have a great potential to be used as electrolyte and

cathode components in solid oxide fuel cells (SOFCs). SOFC is currently

deemed as one of the most promising future power generation devices due

to its high energy conversion efficiency, less/zero pollutant emission

and able to operate on various fuels. Two major concerns that limited

the performance of the current developed SOFC systems are low

electrolyte conductivity and high electrode polarization resistance

[1,2]. Controlling and modifying the microstructural properties of the

ceramics components of SOFC is a promising way to tackle the concerns

and could be achieved by selecting suitable ceramics processing routes

as they greatly affect the microstructure properties of the produced

ceramics materials [3]. Traditionally, a Simple Solid-State Reaction

(SSR) method is used to prepare the perovskite-type oxide ceramics

materials [4-7]. However, this method resulted in a poor microstructural

property of the produced powders due to high temperature of treatment

(> 1400 °C) and the produced powders are frequently contaminated

[8,9]. Hence, Wet Chemical Methods (WCMs) are introduced to overcome the

drawbacks of the SSR method. The WCMs are able to produce fine powders

with high purity and good homogeneity at lower

processing temperature than that of the SSR method [3,10]. One the most

popular WCMs is a sol-gel method. The preparation of materials through

this method is thoroughly discussed in the following section.

Sol-gel Method

A sol-gel method has been introduced in the 1800s to

produce inorganic ceramics and glass materials [11]. It is a process to

form oxide linkages via inorganic polymerization reaction. It starts

with a reaction between molecular precursor and solvent to form metal

organic complexes. The complexes will undergo polymerization process to

yield colloid or sol followed by hydrolysis to form a gel. Then, the gel

will turn into ceramics powder after drying and sintering processes

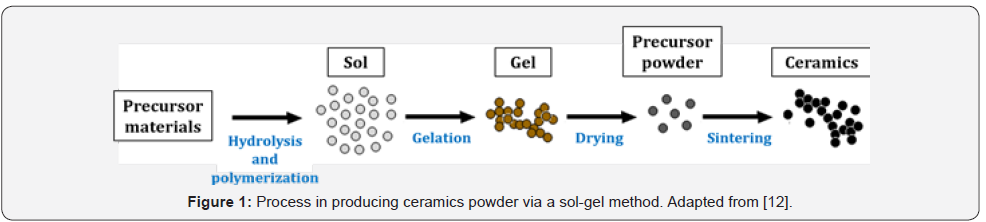

[12]. A simple illustration of the sol-gel processes is shown in Figure

1.

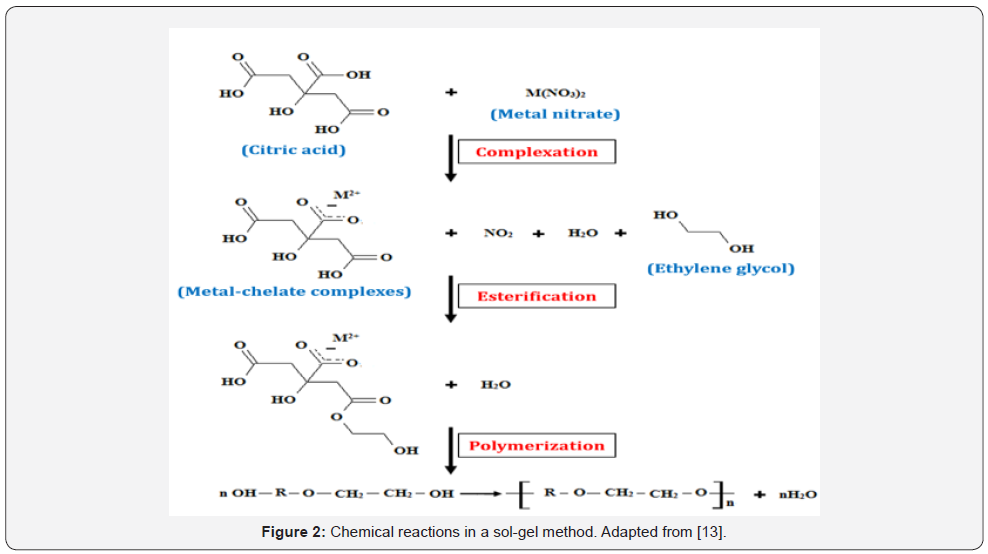

There are two basic chemical reactions involve in

sol-gel method which preserve the homogeneity of the metal salts

(precursor materials) in the solution into gel. The first one is the

complexation between metal ions and chelating agent such as Citric Acid

(CA) and Ethylenediaminetetra-Acetic Acid (EDTA) which provides a stable

metal-chelate in the solution by preserving atomic scale homogeneity.

Another one is polymerization of the complexes with polymerizing agent

or surfactant such as Ethylene Glycol (EG) which forms threedimensional

structures that hinder ion mobility and segregation.

A simple illustration of the chemical reactions which involves in

this method is shown in Figure 2 [13].

Roles of Chemical Agents

Generally, a chelating agent acts to bind all the metal cations

of the precursor materials to form a stable metal complexes in

a precursor materials solution with homogenous distribution

at atomic or molecular level. The addition of chelating agent is

able to control the rate of hydrolysis reaction, phase transition,

particle size and powder morphology [14]. CA and EDTA are

the most conventional chelating agents used to produce various

ceramics materials for SOFC application. They can be used

separately as a single (CA/EDTA) chelating agent [15-17] or

together as a combined (CA-EDTA) chelating agent [18-20]. A

combined chelating agent is better than a single chelating agent

because it is able to bind almost all metal cations and form more

stable complexes than a single chelating agent. Moreover, it is

less sensitive to pH value of the complexes solution and able

to reduce the temperature required for single phase powder

formation [21,22]. Besides, non-conventional chelating agents

such as Triethylenetetramine (TETA), glycolic acid, nitriloacetic

acid and tartaric acid have been also used to improve the

properties of BaCe0.54Zr0.36Y0.1O2.95 electrolyte material for

proton-conducting SOFC application [23].

Ethylene Glycol (EG) is a conventional solvent used in a solgel

method. It acts as polymerization agent or esterification agent

to produce cathode and electrolyte materials such La0.6Sr0.4CoO3-δ

[20], BaCe0.54Zr0.36Y0.1O2.95 [24], Sm1-xCaxFeO3 [25] and SrCox

[13] for SOFC applications. EG aids to form a stable polymer resin

of metal-chelate complexes. The formation of polymer resin

hinders the formation of particle agglomeration by forming rigid

network which controls the movement of metal cations in the

complex solution of precursor materials during heat treatment

process [26-28]. For better properties of the produced powder,

the amount of chelating agent and polymerization agent need to

be optimized and controlled.

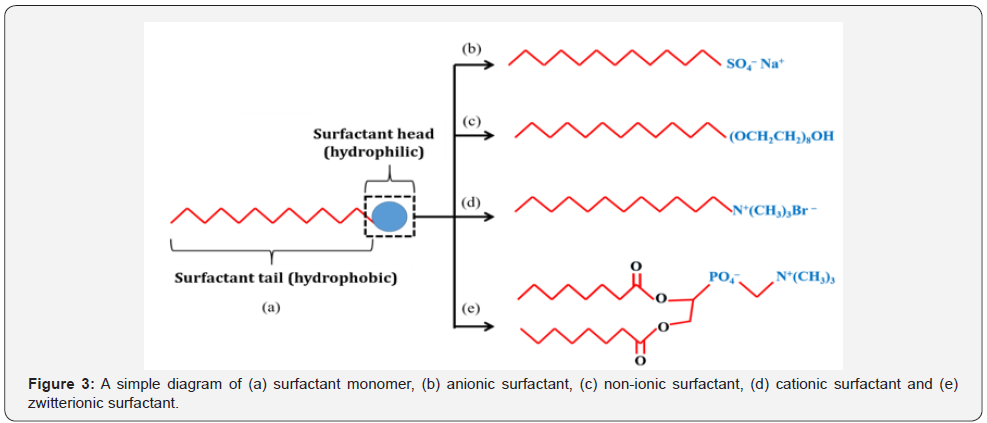

In a modified sol-gel method, a surface-active agent or

simply known as surfactant is used to replace EG as a solvent.

Surfactant is an amphiphilic compound consists of hydrophilic

polar group and hydrophobic non-polar group. The polar and non-polar groups are the head and tail of a surfactant monomer,

respectively. Surfactant is classified into three groups based

on the charge of the polar group which are ionic (anionic or

cationic), non-ionic and dipolar or zwitterionic. The non-polar

group is made up of long-chain hydrocarbon or siloxane chain

[29]. A simple diagram of a surfactant monomer is shown in

Figure 3.

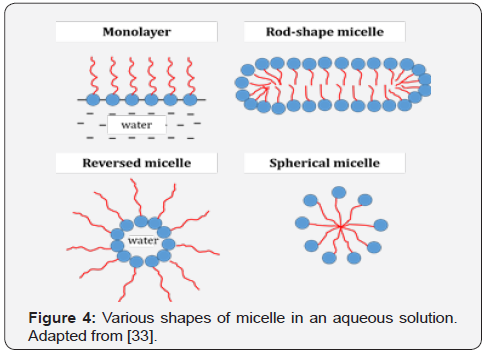

A surfactant can increase miscibility, colloidal stabilization

and particle dispersion in a material with various components

because of its unique properties of self-assembly. These

properties help to reduce the tension of two or more components

in a solution system and change the properties of the surface

of the solution and increase the compatibility between the

particles with different properties in the solution [30,31].

In addition, a surfactant can control the shape and particle

size of the produced ceramics materials. It forms a cluster of

thermodynamically stable supramolecular known as micelle

or microemulsion [32]. Micelle can form in various shapes in

an aqueous solution as shown in Figure 4. It is dependent on

temperature, surfactant concentration, surfactant composition

and pH [29]. The variation in the micelle shapes is one of the

factors that affects the particle shape and size of the produced

powder [24].

There are many surfactants which have been used to produce

ceramic materials for SOFC components via a sol-gel method [33].

Pluronic F127 (tri-block copolymer) and Triton-X-100 were used

to synthesis La0.58Sr0.4Fe0.8Co0.2O3-δ [34,35], and Poly-Ethylene

Glycol (PEG) was used to synthesize La0.6Sr0.4CoO3-δ cathode

materials. Polyvinyl Alcohol (PVA) and Polyvinyl Pyrrolidone

(PVP) were used to synthesize La0.8Sr0.2MnO3-δ cathode material

[36]. All of these surfactants helped to reduce the particle size

from micro to nano, increase the surface area and homogeneity

of the produced powders. The same results were also reported

for the synthesis of electrolyte materials of Yttria-Stabilized

Zirconia (YSZ) [37], Ce0.9Gd0.1O1.95 [38], Ce0.8Sm0.2O2-δ [39], and

BaCe0.54Zr0.36Y0.1O2.95 [24], using various surfactants. Additionally,

surfactant also helps to reduce the temperature required to

produce single phase powder and high-density pellet [38,40].

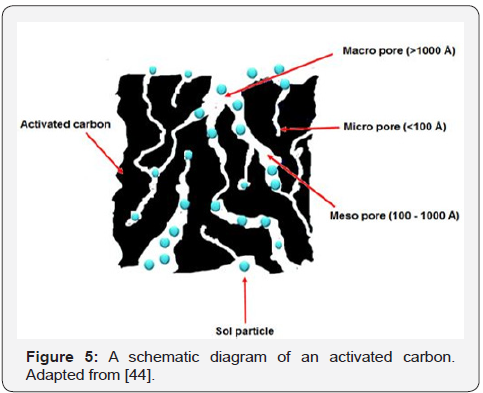

In addition, Activated Carbon (AC) has been introduced

as a dispersing agent in a modified sol-gel method to produce

perovskite-type oxide conductive ceramics for SOFC application.

The use of AC as a dispersing agent is quite a new invention

in sol-gel method. AC, which is a treated form of carbon with

high degree of microporosity, surface area (300-2000m2g-1)

and well adsorption ability, is used to replace the conventional

solvent or surfactant in the conventional sol-gel method. Like

the other chemical agents, AC is also responsible for controlling

the nucleation process, phase development and particle growth

during the synthesis process. However, it has different reaction

mechanism as compared with the other chemical agents. AC traps

the metal complexes in precursor solution in its highly porous

microstructure through van der Waals attraction, creating

well-dispersed particles of the produced ceramic materials

after calcination process (Figure 5). Its potential in modifying

microstructure of perovskite-type ceramic materials with good

electrochemical performance particularly for SOFC application

have been reported by Ismail et al. [41] and Abdul S et al. [42,43].

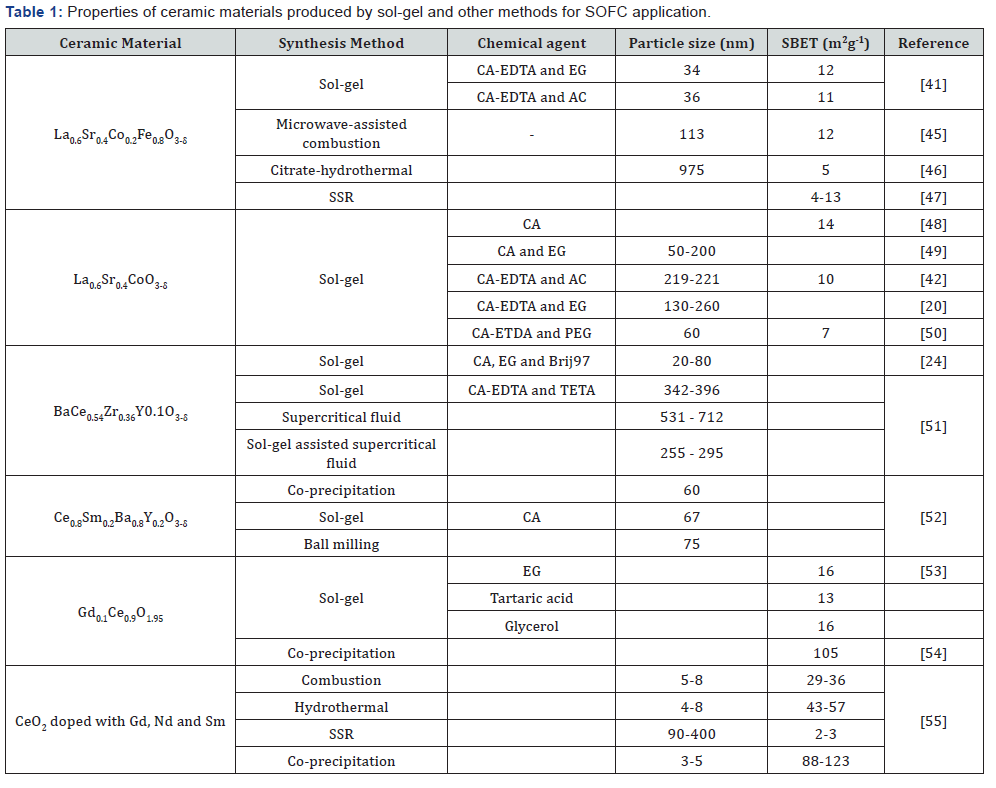

The improved properties of the produced ceramics materials

by sol-gel method are very important for better electrochemical

performance of the SOFC components [44-48]. The properties

i.e. particle size and BET specific surface area (SBET) of some

common ceramic materials for SOFC application produced by

different chemical agents via sol-gel method and other synthesis

methods are tabulated in Table 1. It can be seen that the

properties of the produced ceramic materials are different. It is

due to the different chemical agents used in the sol-gel method

and the different in the method used to produce the ceramic

materials [49-52]. The discrepancy in the mentioned properties

might also be contributed by the different in the heat treatment

process and synthesis parameters applied to obtain a single

perovskite phase of the ceramic materials [53-55].

Conclusion

A sol-gel method is regarded as a promising synthesis route

to produce better properties of ceramics materials for SOFC

electrolyte and cathode components. The chemical agents

used in this method have been proved to significantly affect

the properties of the produced materials such as particle size

and SBET. Given that research on the sol-gel method has been continuously improving with time, many other materials

can be used as chemical agents. Additional studies of basic

understanding on how the chemical agents work and what are

the condition they work at the best, including composition,

pH, concentration and processing temperatures much be

investigated in detail.

Acknowledgement

The authors would like to acknowledge the Research

University grant (DIP-2016-005) provided by Universiti

Kebangsaan Malaysia. Abdullah Abdul Samat thankfully

acknowledges the Ministry of Higher Education of Malaysia and

Universiti Malaysia Perlis for the SLAB/SLAI PhD scholarship.

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment