Piezoelectric and Dielectric Properties of PZT-Epoxy Composite Thick Films-Juniper Publishers

JUNIPER

PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

Composite piezoelectric thick films are envisioned

for energy harvesting, energy storage, and advanced sensor applications.

This work focuses on PZT-epoxy-aluminum thick films that were

fabricated using a two-step spin coat deposition and annealing method.

The volume fraction of the PZT filler ranged from 0.2 to 0.4, and the

aluminum volume fraction was varied from 0.10 to 0.17 for each PZT

volume fraction, respectively to ascertain the percolation range of the

devices and the influence of the aluminum on the device piezoelectric

and dielectric properties. An aluminum filler was included in the

PZT-epoxy composite to enhance the polarization process of the composite

and to enhance the dielectric properties of the composite. The

piezoelectric strain coefficients d33 and d31, and

capacitance were measured and studied as a function of aluminum volume

fraction and top electrode material (silver and gold). It was determined

that beyond a critical volume fraction of aluminum, the aluminum

particles formed conductive pathways within the composite (percolation

threshold region) which diminished piezoelectric strain coefficients

beyond the percolation threshold value. The percolation thresholds for

these samples were found to occur from 0.13 and 0.17 volume fraction of

aluminum, which agrees with theoretical predictions. SEM micrographs

were used study the interactions between various phases of the

composite.

Keywords: Aluminum; Thick films; Silver; Biomedical

Abbrevations:

MOD: Metal Organic Decomposition; MOCVD: Metal Organic Chemical Vapor

Deposition; PLD: Pulsed Laser Deposition; SEM: Scanning Electron

Microscopy

Introduction

Ferroelectric films have been of interest over the

last 20 years because of the possibility of using them for non-volatile

memory applications [1-3], MEMS [4-6], ultrasonic devices [4,7], battery

separators [8-10], biomedical scaffolds [11] and energy harvesting

devices where they are coupled with batteries [12]. The properties if

piezoelectric films cannot be compared directly with those of bulk

materials of the same composition because their processing and

electrical properties differ. Previous work on the preparation of

piezoelectric films includes RF planar magnetron sputtering [13,14], ion

beam sputtering [15] or DC magnetron sputtering [16], where most

recently, researchers have succeeded in fabricating films using various

chemical methods of deposition such as; metal organic chemical vapor

deposition (MOCVD) [17- 19], chemical solution deposition [20,21],

metal-organic decomposition (MOD) [22,23], and also pulsed laser

deposition (PLD) [24-26]. The sol-gel method has the benefits of

compositional control, reduced temperature processing of highly uniform,

dense, crack-free films and low cost of fabrication [27,28]. These

methods of processing ferroelectric films have

been used with notable success to produce piezoelectric ceramic films

comprised of Lead Zirconate Titanate (PbZrxTi1-xO3 also known as, PZT).

PZT has a high dielectric constant, ferroelectric, piezoelectric, and

pyroelectric properties. The ideal properties of PZT have made its

application to transducer, sensor and actuator devices ubiquitous.

However, the poor mechanical strength of these devices has limited their

life cycle and performance. Therefore, interest in polymer-ceramic

[29-33] (and ceramic-ceramic [34,35]) composites has emerged as an area

of interest because polymers are flexible, low cost, easily processed

[36,37] and able to be polarized under the influence of an external

electric field [38].

Piezoelectric ceramic/polymer composites possessing

various connectivity patterns have been the focus of much study over the

past several years [34, 35, 39-42]. Among the composites examined, the

simplest types are those with 0-3 connectivity [39,43]. Piezoelectric

composites with 0-3 connectivity consist of piezoelectric ceramic

particles dispersed in a three dimensionally connected matrix [1, 5,

29-32, 34, 35, 44-48]. The advantages of these composites lie in the

ease in which they may be processed

into fairly complex shapes, including but not limited to thin sheets,

molded shapes and extruded bars and fibers [39]. The most documented

of piezoceramics used in composites such as these is PZT

[4, 20, 42, 49-52].

Banerjee et al., [34] studied the influence of aluminum

inclusions on the dielectric properties of three-phase PZT cement

aluminum composites, where the aluminum and PZT particles

were dispersed in a Portland cement matrix. The fabricated

samples were nominally 6mm in thickness and were poled at a

low poling voltage of 0-6kV/mm at a temperature of 160 ͦC in air.

It was reported that three-phase composites possessed a higher

piezoelectric strain coefficient (d33) than two-phase composites.

The highest value of d33 observed for the three-phase composite

was 8.1 pC/N for volume fractions equal to 0.7 and 0.2 for PZT and

Al, respectively. This d33 value for the three-phase piezoelectric

composite was 1.64 times the value measured for the two-phase

composite. Banerjee et al., [53] also investigated the influence

of micro and nano sized aluminum inclusions in a three-phase

PZT-Epoxy-Al bulk composite. The fabricated composites were

~ 6mm thick and were comprised of micron sized aluminum

powder and PZT. These devices had higher dielectric constants

that the composites that incorporated nanosized aluminum

particles (both sets of samples were polarized at the same value:

0.2 kV/mm in air) due to interfacial effects, contact resistance and

increased agglomeration. Specifically, for composites with PZT

volume fractions equal to 0.20, 0.30 and 0.40 and micron- sized

aluminum particles, the dielectric constants were equal to 405.7,

661.4, and 727.8 (pC/N), respectively. On the other hand, the

dielectric constants for composites that were comprised of nano

sized aluminum particles the (the same PZT volume fractions)

dielectric constants were equal to 233.28, 568.81, and 657.41

(pC/N), respectively. They concluded that samples that contained

micron sized aluminum inclusion yielded higher dielectric

constant values compared to the Nano sized aluminum inclusions,

which resulted in higher dielectric values for samples with micron

sized piezoelectric fillers.

In this work, PZT-aluminum-epoxy thick film composites

were fabricated where the volume fractions of PZT and Al were

varied from 0.20 to 0.40 (increments of 0.10) and 0.0 to 0.17,

respectively. A minimum of three samples were fabricated for each

of the studies. In addition, two different types of top electrodes

(sputtered gold and silver paint) were prepared and compared in

terms of piezoelectric and dielectric constants. The change in the

piezoelectric and dielectric properties with respect to time was

also observed over a five-day period.

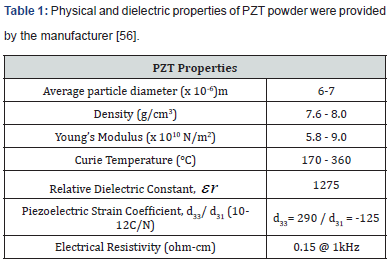

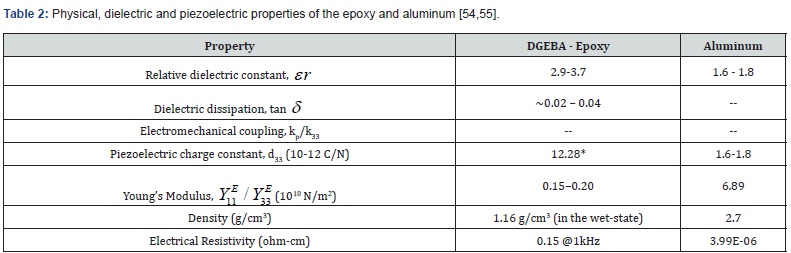

Materials and Methodology

The materials used in all experiments were PZT powder

(READE), DGEBA Epofix TM Cold-Setting embedding resin

(Electron Microscopy Sciences) [54], and aluminum -99.97%, 200

mesh i.e. ~ 75μm (Acros Organics) and 0.0254mm stainless steel

substrates (Alfa Aesar). The piezoelectric and physical properties

of the materials are presented in Table 1 & 2, respectively. The

properties for the aluminum were obtained from the manufacturer

website [55,56].

*Experimental values

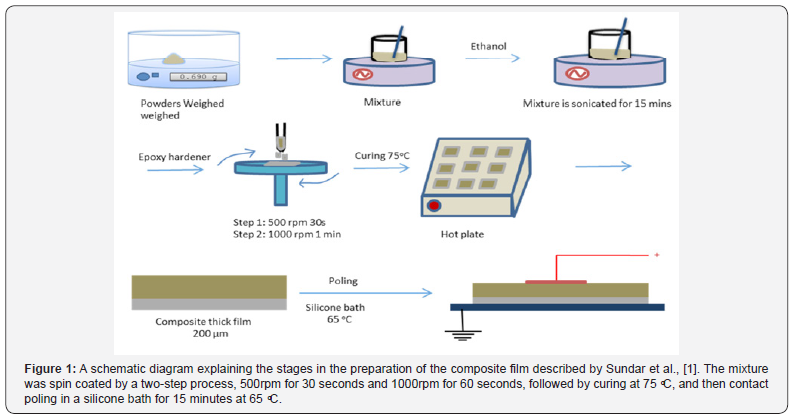

PZT epoxy aluminum thick composite films were deposited

onto stainless steel substrate using a spin coat and deposition

technique. The stainless-steel squares were 25mm x 25mm and

0.0254mm thick. An overview of the fabrication process for the

devices is provided in Figure 1. The volume fractions of the PZT

and aluminum were varied from 0.20 to 0.40 and 0.01 to 0.17,

respectively. As shown in Figure 1, the PZT, aluminum and epoxy

were weighed to achieve the desired volume fraction and then combined in a beaker. The contents in the beaker were hand

stirred for 5minutes and 5ml of ethanol was added to this mixture.

The mixture was subsequently sonicated in an ultra sonicator

for 1hour, while being hand stirred every 15minutes. The epoxy

hardener was then added to the mixture. The final compound

was then poured onto the stainless-steel substrate using a

dropper while the spin coater was rotated from 100 - 500rpm

for 30seconds, and subsequently by 1000rpm for 60seconds. The

initial low rpm enabled an even distribution of the compound

over the substrate.

After the spin coating process, the samples were removed and

cured on a hot plate in the presence of air for 8 hours at 75 ͦC.

The samples were then cooled for 24 hours and eventually coated

with colloidal silver paint as the top electrode. Samples were then

contact poled at a voltage of 2.2kV/mm at 65 ͦC in a silicone oil

bath for 15 minutes. An additional set of samples were prepared,

where the volume fractions of PZT and aluminum were 0.3 and

0.05, respectively. Sputtered gold was used as the top electrode for

these samples instead of colloidal silver paint. All samples were

then wrapped in aluminum foil and stored at room temperature

in the air for

24 hours to remove any remaining residual charges that may

be on the samples.

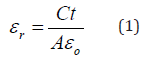

Dielectric and piezoelectric characterization

The piezoelectric strain coefficients, d33 and d31, and capacitance,

were measured using a Piezo Meter System manufactured

by Piezo Test, Piezoelectric Materials & Device Testing Company,

while the resistance was obtained using an Impedance/Gain

Phase Analyzer (HP4194A). All the measurements were taken after

polarization of the sample. The dielectric constant was calculated

using the expression,

In Equation (1), is the capacitance in Farads, A is the area of

the sample, is the permittivity of free space ≈ 8.854×10e-12Fm–1;

and t is the thickness of the sample. The impedance analyzer was

used to measure the real part of the resistance, R, of each sample,

and the resistivity was determined from Equation (2),

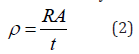

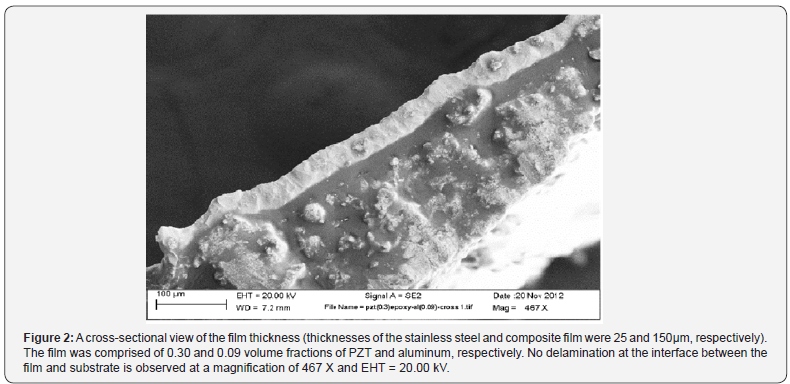

Material morphology and surface characterization

The surface morphology of the individual phases and the

composite was examined using scanning electron microscopy

(SEM) micrographs. Two types of images were gathered for these

composites, one was from the top surface of the sample, which

provides information about the distribution of the individual

phases within the polymer matrix, and the other was the crosssectional

image along the thickness of the sample. The crosssectional

image represents how the particles are distributed along

the thickness and a macroscopic view of the composite substrate

interface.

Results and Discussion

Surface morphology

The surface morphology of the composite films and the

particle distribution within the composite were observed via

scanning electron microscopy (SEM) and energy dispersive X-ray

spectroscopy (EDS) micrographs. PZT epoxy-aluminum samples

that were comprised of 0.30 PZT and 0.09 aluminum (by volume

fraction) were observed.

The cross-sections of the samples were obtained by cutting

the sample using a blade and placing the samples onto the SEM stud to reveal the samples cross-sectioned thickness or surface

morphology.

In Figure 2, a SEM micrograph of the cross-section of the film

is presented at 467× magnification. There do not appear to be any

microscopic pores or delamination points at the interface between

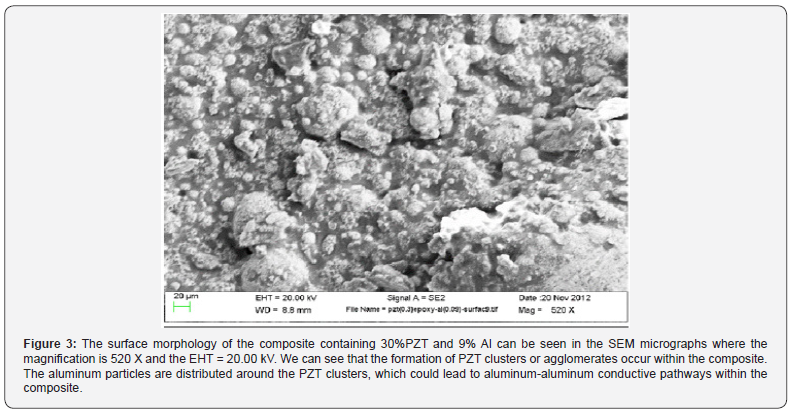

the substrate and the film. In Figure 3, the surface morphology of

the composite film is depicted at a magnification of 520 X. PZT

and aluminum particle agglomeration are observed in this SEM

micrograph. The agglomeration may be attributed to several

mechanisms of agglomeration, e.g. Brownian, gravitational,

turbulent, and electrostatic, where the gravitational form could

be mitigated n theory by the spin coating process. The as received

PZT and aluminum powders tend to naturally form clusters that

vary between 5-20μm in the case of aluminum and 10-25μm

in the case of PZT as shown in Figure 4A and Figure 4B, where

these agglomerations are most likely attributed to electrostatic

agglomeration. Though ethanol was used to change the surface

charge of the powder particles, its addition did not effectively

change the pH of the solution to negate the surface charge on

the all of the particles, which diminished its effectiveness in

counteracting the electrostatic forces between particles. The

extent of the effective- ness of the ethanol on the pH of the solution

was also a function of the number of particles within the colloidal

sol gel.

Piezoelectric and dielectric characterization

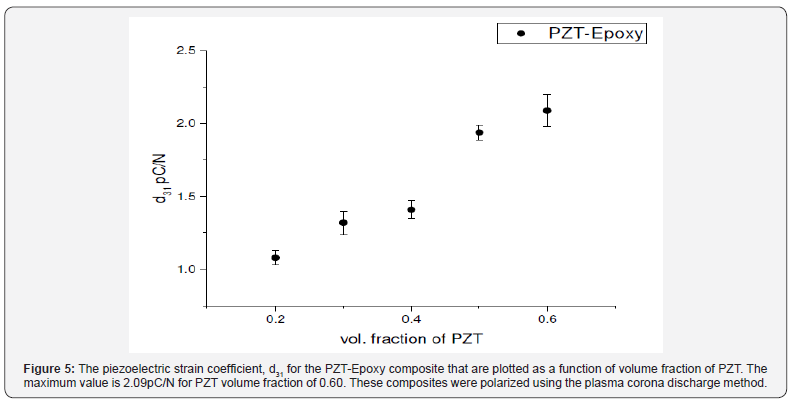

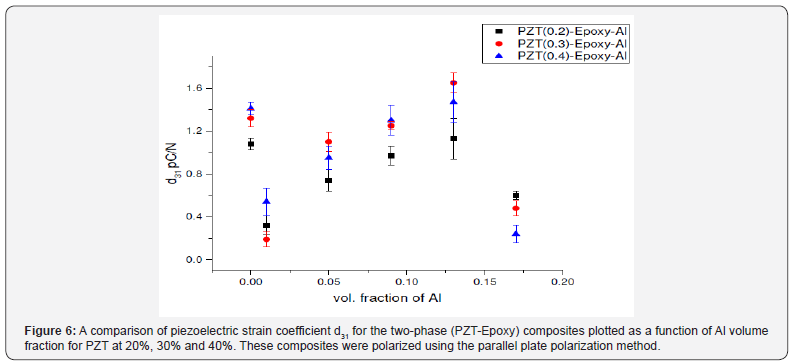

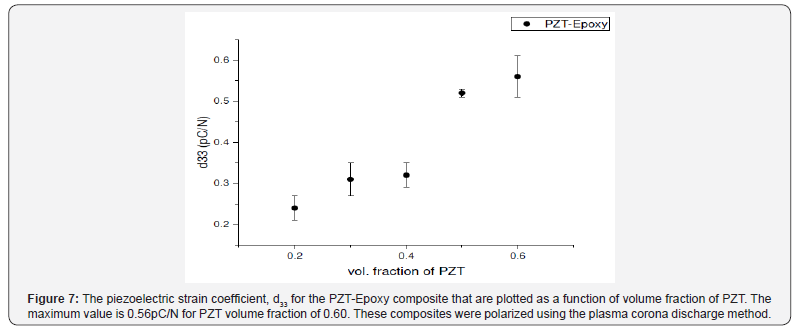

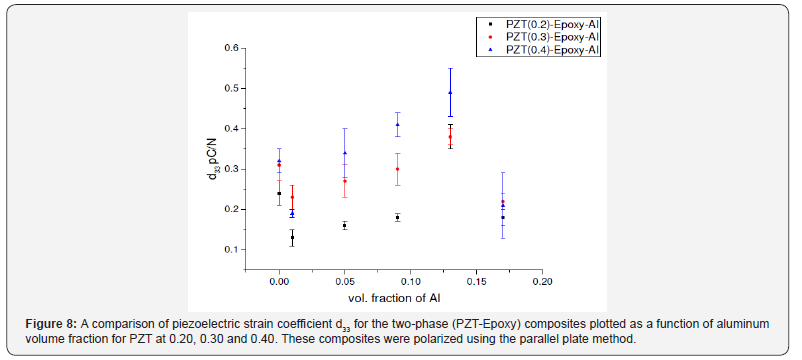

In Figure 5 & 6, the piezoelectric strain coefficients, d31 and

d33, for PZT-epoxy film composites are plotted as a function of PZT

volume fraction. The films were fabricated in a similar manner

as the 0-3-0 films, only they were Corona polarized at 15 kV/cm,

instead of Contact Parallel Plated polarized. In Figure 7 & 8, the

piezoelectric strain coefficients, d31 and d33 of the composites are

plotted as a function of Al (0.0 to 0.17) for volume fractions 0.2, 0.3

and 0.4 of PZT, respectively. The PZT-epoxy samples were Corona

polarized, but the three phase, 0-3-0 composites were parallelplate

contact polarized. As expected, the piezoelectric strain

coefficients, d31 increased with PZT content and aluminum content

up to 0.13, beyond which there is a steep decline in d31 values. The

increase in d31 values is consistent with many re- searchers such

as [42,49,57], who demonstrated increased values of d31 with

increased PZT content within a piezoelectric polymer composite. A

similar trend is expected for d33 values of the composite. However,

the magnitude of the d31 values is considerably higher than the d33

values owing to the higher strain in the direction along the 1-axis

as compared to the strain in the 3-axis. The range of the values of

d31 and d31 are consistent with [49,58] where the active particle

size was <34m with a poling voltage equal to 10kV/mm at room

temperature, which is consistent with the data presented here.

The differences in the d31 and d31 values for the 0-3 and the 0-3-0

composites are greater for lower volume fractions of PZT, but the

advantage of Corona poling over Contact Parallel plate is evident

at lower volume fractions of aluminum.

However, at a higher volume fraction of the aluminum (0.13),

the d31 values slightly surpassed those of the PZT-epoxy values

for PZT volume fractions of 0.3 and 0.4.

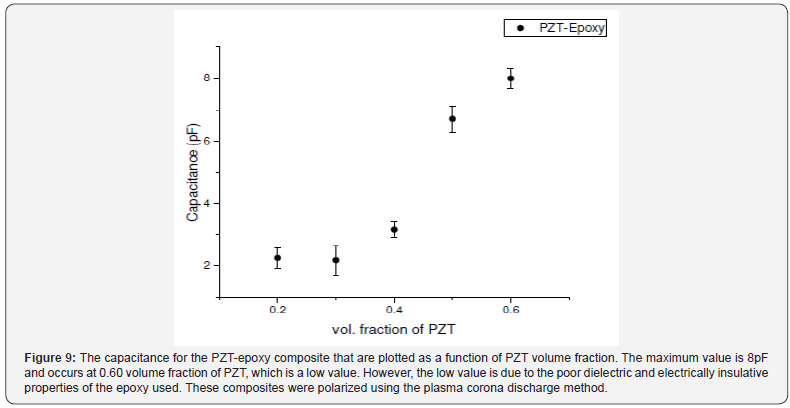

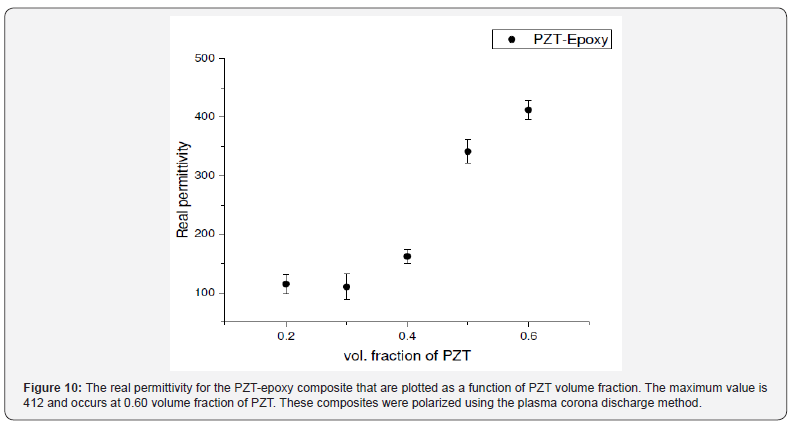

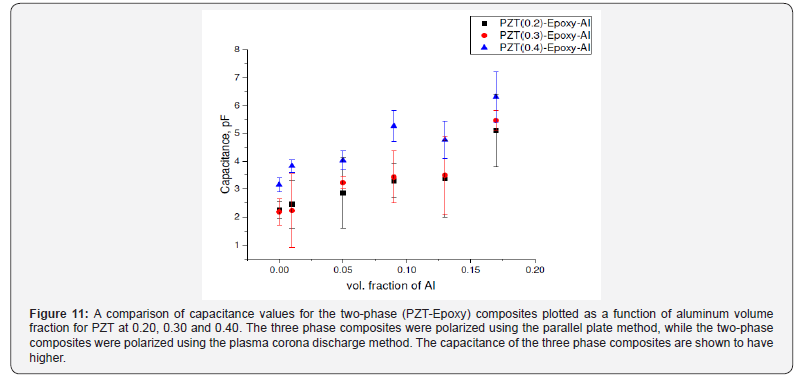

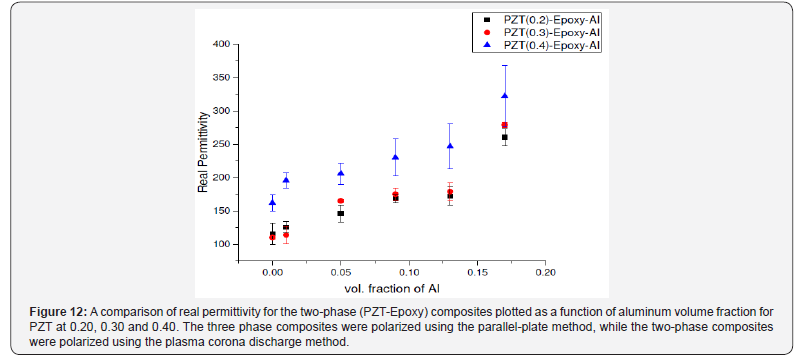

The capacitance and dielectric constants of the two-phase

composites are presented in Figure 9 & 10. The capacitance

and dielectric constants were found to increase with PZT

content, where the maximum value was ~8 pF and ~412 for the

capacitance and permittivity, respectively for a volume fraction of

0.60 for PZT. It was observed that as the PZT con- tent increased,

the polarization of the composite enhanced due to PZT’s inherent

ferroelectric property. Hence, higher overall dielectric constants

were observed. It is expected that as the polarization density

increases, the ability to store charge in the materials is enhanced

as a function of the polarization vector magnitude. The dielectric

constants for the three-phase samples are presented (Figure 12).

The dielectric constants for all samples increase with volume

fraction of PZT and aluminum as was similar to the observations

of [59-61]. All samples containing the aluminum filler had higher

dielectric constants than their two-phase counterparts. The

three-phase system with aluminum particles closely resembled a

percolative system [62-68].

This interfacial polarization or the so-called Maxwell-Wagner

effect is responsible for the enhancement of the dielectric constant

[63,64]. This increase in dielectric constant corresponds to an

increase in volume fraction of aluminum particles and culminates

at a critical value, known as the percolation threshold. Beyond

this critical value the system begins to conduct electricity due to

either (i) electron tunneling or electron hopping effect and/or (ii)

the presence of conductive pathways, which geometrically align.

Beyond this percolation range, the composite thick films cease to

be a dielectric and become electrically conductive [63, 64]. The

dielectric constant values increased near percolation threshold

due to the presence of micro-capacitor networks. These networks

are formed by neighboring conductive filler particles [65-68] that

sandwich PZT particles that are insulated by the polymer matrix.

Once the micro capacitor networks begin to accrue in number,

they contribute to an overall increase in capacitance [69,70] of

the overall sample. The creation of these networks results in an

increase in the local electric field when the conductive fillers are

close together near percolation which pro- motes migration and

accumulation of charge carriers at the interfaces between the

aluminum particles and the insulating polymer matrix. These

generated charges are then accumulated at the interface and once

the conductive particles appear too close to one another they

are relaxed by tunneling or ohmic conduction [63, 65-68]. The

maximum value of dielectric constant was observed for samples

that contained 0.40 PZT and 0.17 aluminum.

Analysis of piezoelectric effect as a function of top electrode

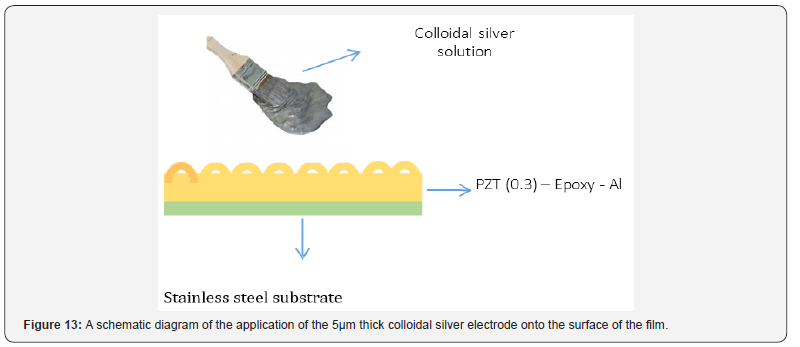

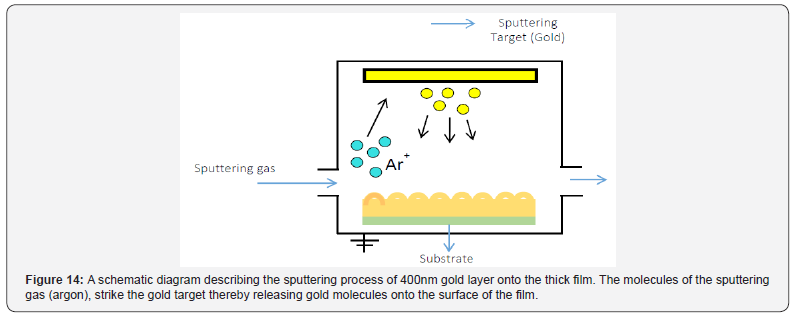

Gold and silver top electrodes were applied to PZT

(0.3)-Epoxy

(0.05) samples to evaluate its influence on the electromechanical

properties of the composite. Colloidal silver solution was applied

as the top electrode with 5μm thickness (Figure 13) and 400nm

gold was sputtered on the sample using a sputtering machine

(Figure 14).

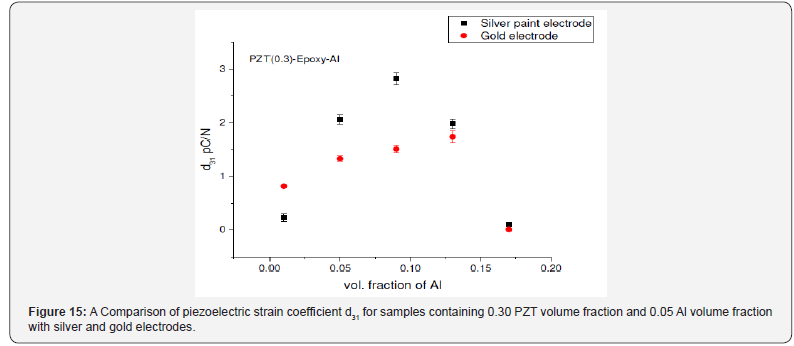

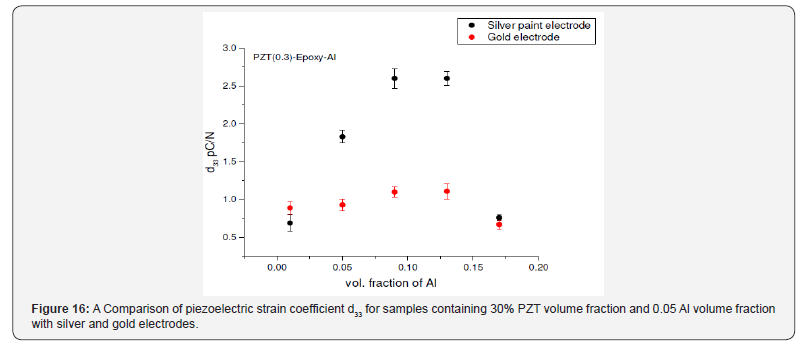

The electron transport properties at the interface of the

composite thick film surface and the device electrode are

influenced by the surface characteristics, such as the surface

morphology of the thick films, the contact resistance and the total

number of contact points connecting the thick film surface to the

surface of the device electrode [71-73]. To draw a comparison

between different top electrodes, the thick films were deposited

with gold (Au) and silver (Ag) electrodes. The electrical resistivity

and conductivity values are different for both materials. The

variation in the piezoelectric strain coefficients d33 and d31 of the

thick film are shown in Figure 15 & 16. The values are enhanced

by the addition of the metallic electrodes below the percolation

threshold. This improvement in the d33 and d31 values is due to the

decrease in the contact resistance and increase in the mobility

of electrons at the interface between the film surface and the

electrode due to the presence of the metallic layer [72]. We can

see a maximum d31 and d33 values for the samples with silver

electrode are 2pC/N and 2.5pC/N, respectively occur at ~13% Al.

These values are higher than that of gold, d31 and d33 are ~1.8pC/N

and ~1.2pC/N, respectively because of the decreased electrical

resistivity of silver (Ag ~0.00955 10-8 Ωm and Au ~0.0502 10-8

Ωm) [74].

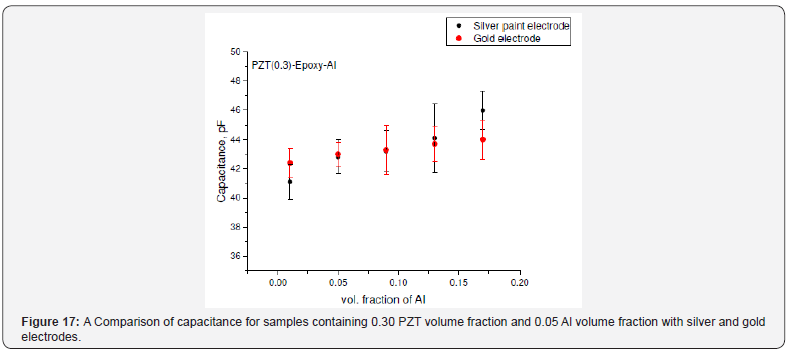

The capacitance values are enhanced by the addition of the top

electrode. The top electrodes were applied to samples containing

a PZT volume fraction equal to 0.3 and aluminum volume fraction

equal to 0.05. The capacitance for of the samples with the gold

electrodes were ~43pF, ~42.8pF for the silver electrode and

~3.5pF when no electrode was applied. The enhancement of

the capacitance could be due to several factors such as electron

tunneling due to an increase in the intensity of local electric field

[63]. Also, the conductive layer reduces the losses due to metal

insulator transition and other interface defects as compared to

the compo- site without a conductive layer [72].

Effect of aging of samples

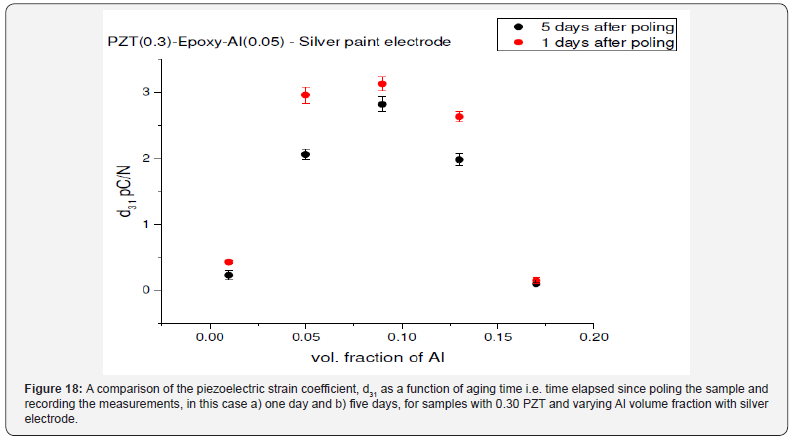

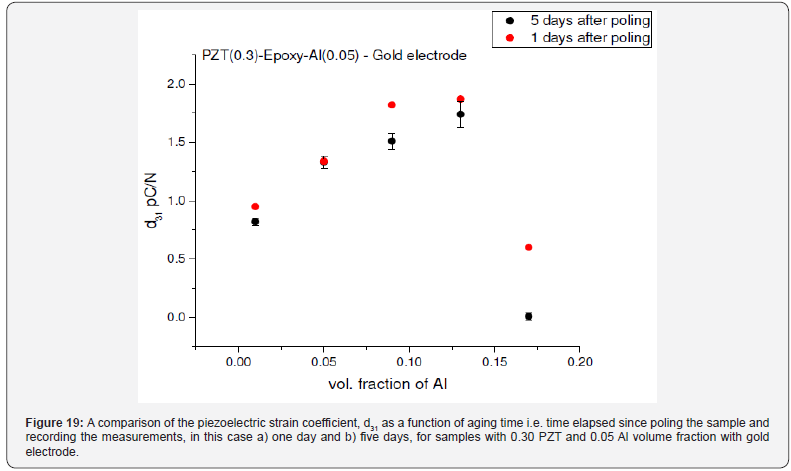

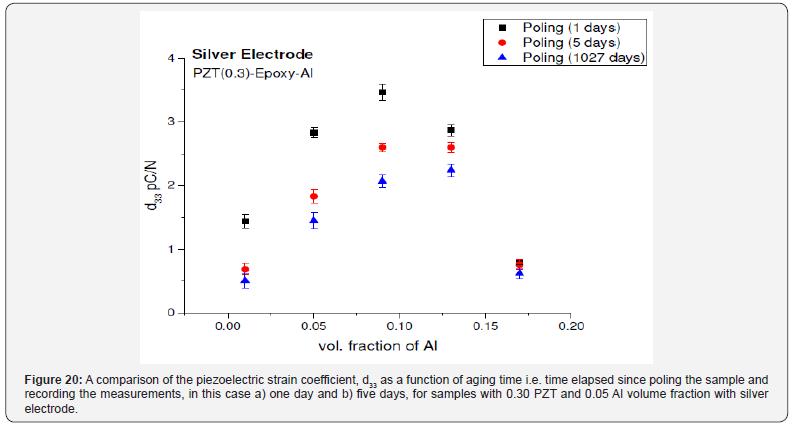

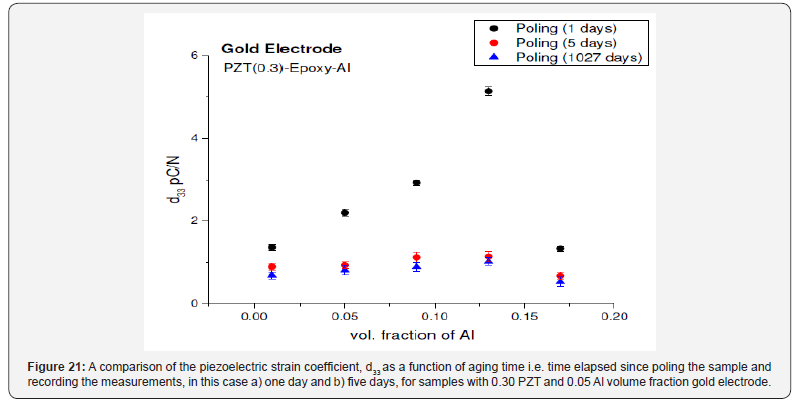

The composite properties were also recorded as a function

of time: 1, 5 and 1027 days of poling, to study the effect of aging

on the electromechanical properties of the composite. The

values measured after five days were slightly lower than the

values recorded after one day as indicated in Figures 17 & 18

through 21. This happened because the samples reached remnant

polarization gradually over time, and thus attained lower d33 and

d31 values as some of the dipoles that were forced to return to their

original position. The samples were measured again, 1027 days

after poling, the d31 and d33 values reduced only slightly (0.105-

0.235 less compared d33 of 5 days after poling), however they did

observe a similar trend in values varying with aluminum volume

fraction, as shown in Figure 20 & 21.

Conclusion

Three-phase piezoelectric PZT-epoxy-Al thick film composites

were fabricated and poled using parallel-plate contact poling

method. The volume fractions of PZT and Al were varied from

0.2 to 0.4 and 0.0 to 0.17 respectively. The piezoelectric strain

coefficient, d33 and d31 and the dielectric constant increased with

PZT and Al volume content. Furthermore, the piezo- electric strain

coefficients, longitudinal and axial, increased with Al volume

fraction culminating at 0.13, beyond which the values began to

drop. Two different top electrodes were applied to the samples,

gold and silver and their values were compared. Silver proved

to result in better overall properties due to reduced electrical

resistivity at the interface. An aging study was also carried out

to measure the piezoelectric strain coefficients between 1, 5 and

1027 days. The results showed that the values gradually dropped

over time, falling quickly between 1 and 5 days, and more gradually

between 5 and 1027 days.

Acknowledgement

This material is based upon work supported by the National

Science Foundation under Grant Numbers: EEC1659818, EEC1263250 and EEC1407266. In addition, we would like

to acknowledge support from the New Jersey Space grant

Consortium.

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment