Hydrolytic Degradation of Thermoplastic Copolyester Nanocomposites-Juniper Publishers

JUNIPER

PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

Thermoplastic copolyesters (TPE-Es) are multi-block

copolymers commonly incorporating hard (polyester) and soft (polyether)

blocks. Multifunctional epoxy-based chain extenders (TGDDM) are one of

the additives that serve to reverse molecular weight (MW)

damage caused by the process of hydrolysis of TPE-E. There are two

functional groups that are capable of additional reactions on the

terminal hydroxyl and carboxyl groups of TPE-E. Considering the hydrogen

bonded hard segments in hard domains are less susceptible to hydrolysis

compared to the non-hydrogen bonded equivalents, the phase separated

morphology of polyether-polyester copolymers based TGDDM also provides

to the long-term stability. The molecular weight of TPE-E was determined

by GPC and the thermal and tensile behaviors were investigated.

Keywords: Thermoplastic copolyester; Crosslinking; Hydrolysis; Mechanical properties

Abbrevations: TPE-Es: Thermoplastic Copolyesters; MW: Molecular Weight; TGDDM: Tetraglycidyl-4,4-Diamino-Diphenylmethane;

Introduction

Polyester hydrolysis produces hydrophilic acid

(carboxyl) end groups in the polymer, which increase the ability for the

polymer to absorb water because of the decrease in its surface

resistance and hydrophobicity [1-3].

Chain extenders remain necessary in improving the

molecular weight of TPE-E and, consequently, broaden their industrial

applications. Chain extenders help in the substitution of polyester

hydrolysis-caused molecular weight damage, leading to the production of a

polymer with desired melting strength and rheological properties. The

chain extenders function effectively, predominantly due to their

bi-functional groups that inherently react with polymer terminal groups.

Moreover, specific chain extenders,

such as tetraglycidyl-4,4-diamino-diphenylmethane (TGDDM), are vital in

the enhancement of TPE-E molecular weights. Consequently, TPE-E would

have improved rheological, mechanical, and thermal characteristics [4].

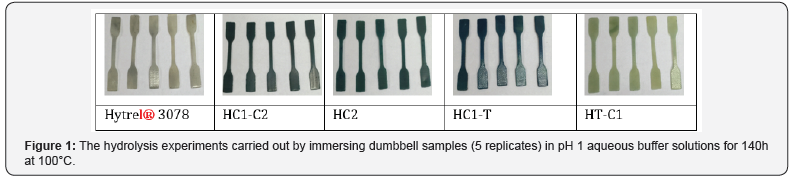

Hytrel® 3078 is a brand of TPE-E (copolyesters,

COPEs) under the trademark of DuPont. Hytrel 3078 nanocompsite prepared

by reactive extrusion-based masterbatch (HC1-C2), dry feed (HC2) of

organo-fluoromica combined with TGDDM, the post-addition of TGDDM

(HC1-T) and the direct-addition of TGDDM- organo-fluoromica (HT-C1) were

compared for their resistance to hydrolysis in aqueous buffer solutions

for 140 h solution at 100°C at pH 1 (Figure 1).

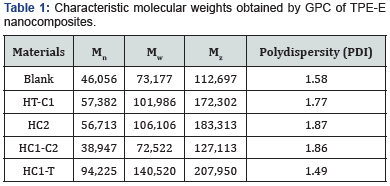

The enlargement of the MWD for the nanocomposites can also be indicated by the polydispersity index (PDI= Mw/Mn),

besides extremely high molecular weights above 2 × 106g/mol are also

obtained. These outcomes show modifier chain extension efficiency which

has an effect on the rheological characteristics of the material.

The PDI of the host polymer before and after

reactive modification via different processing routes (blank TPE-E,

HT-C1, HC2, HC1-C2 and HC1-T) are also given in Table 1. A significant

decrease in Mn of HC1-C2 nanocomposites occurred during a

masterbatch of reactive nanofiller in TPE-E. It is still expected

that there may be thermal and thermo-oxidative degradation

processes associated with reactive processing this TPE-E, which

are responsible for the molecular weight decrease in the melt

compounded TPE-E. The relatively low Mw, suggesting that

HC1-C2 is less crystalline than other modified nanocomposites,

and therefore it was not possible to obtain high molecular weight

TPE-E. Higher molecular weight may be obtained if the TGDDM

is post-added with TPE-E matrix for HC1-T. It was shown that

the Mn of the HC1-T was twice that of first adding of TGDDM into

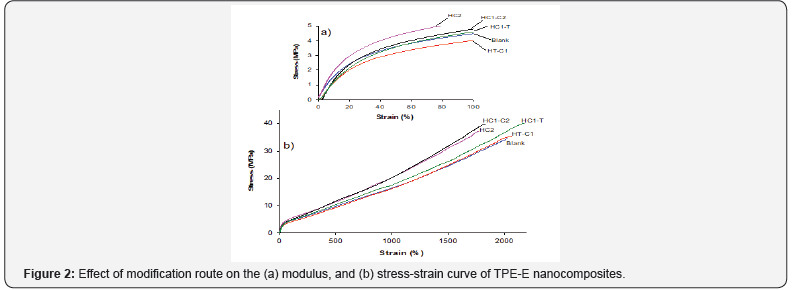

TPE-E (HT-C1). This halving of molecular weight resulted in the

HT-C1 having a tensile strength of 35MPa, which was 4.9MPa

lower than that of the HC1-T (39.9MPa) (Figure 2). The postaddition

of TGDDM decreased the PDI of TPE-E nanocomposite.

This contrasts with the significant improvement in Mw of HC1-C2.

The high PDI value can also be attributed to higher branching

formation of TPE-E. Twin screw extrusion, which compounds

thermally-sensitive materials, yields a far greater shear energy

than single screw extrusion, which results in a loss of molecular

weight and a decrease in properties and performance [5].

The thermal and mechanical properties of polymers

are influenced by polydispersity of the hard segments. The

presence of many epoxy groups gives rise to a highly crosslinked

network within the nanocomposite. As seen in Figure

3, the addition of TGDDM in HT-C1, HC1-C2 and HC1-T clearly

shifted the exothermic heat of crystallisation peaks of the hard

segment to higher temperatures. The result of these studies

indicates that hard segments of uniform length crystalise faster

and better than hard segments of non-uniform length. However,

the hard segments represent a physical cross-link which report

elastomeric properties to the soft phase. The hard-soft segmental

solubility parameters and aligned hard and soft segments,

polydispersity and molecular weight, as well as the processing

and thermal history of the TPE-E host matrix are essential factor

to be considered to the tensile properties demonstrated by the

nanocomposites [6].

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment