Effects of Nanoparticles on Rheological Behavior of Polyacrylamide Related to Enhance Oil Recovery- Juniper Publishers

JUNIPER

PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

The effect of nanoparticles SiO2, TiO2 and Fe2O3 on

the rheological behavior of anionic polyacrylamide and a mixed assembly

of polymer and cationic surfactants were measured systematically by

shear viscosity and oscillatory testing at different concentration of

Nano-materials. The results of shear viscosity measurement indicate that

for all of the systems, the shear viscosity increases with the addition

of nanoparticles and show shear thinning behavior at low shear rate. In

the oscillatory test, all of the systems show elastic behavior, which

depend on the concentration of nanoparticles. The storage modulus (G’)

and loss modulus (G’’) increased as nanoparticles concentration

increase. The core flooding experiment were also done with

polymer-surfactant solution in presence and absence of nanoparticles and

the obtained result indicates the higher oil recovery in presence of

nanomaterials. In enhance oil recovery process; the viscosity and

viscoelasticity are key parameters for the success of the recovery

process.

Keywords: Wettability; Viscoelasticity; Displacement efficiency; NanoparticlesIntroduction

Due to the increasing demand of energy and

diminishing amount of conventional oil, the oil industries have been

relying on enhanced oil recovery methods for decades. Presently, lots of

researches are being carried out globally to improve enhanced oil

recovery techniques to fulfill the demands of oil. Recently, the use of

nanoparticles in enhance oil recovery has been proved very efficient.

With a nano size and large surface area to volume ratio, nanoparticles

have the potential to penetrate the pores in the reservoir rocks where

conventional enhance oil recovery process are unable to. The

nanoparticles can alter the oil reservoir characteristics such as

mobility ratio, wettability, interfacial tension, injected fluid

viscosity and are stable than the polymer-surfactant at harsh and saline

conditions [1-3]. The oil recovery decreases by increasing the salt

concentration during the polymer flooding, whereas in the case of

flooding with a suspension of nano-silica in the polymer, decreasing the

rate of oil recovery is lower [4]. The nanoparticles are more capable

of the reduction of interfacial tension and the alteration of

wettability in the case of light oil reservoir [5].

In the last decade, nanoparticles have attracted many

researcher’s attention in the field of enhance oil recovery due to

their unique properties. Maghzi et al., [6] reported that at the same

salinity, the oil recovery is 10% higher with nanoparticles than the

polymer flooding in the absence of nanoparticles. Hu et al., [7]

reported that with 5ppm concentration of nanoparticles recovered the

original oil in place about 35.8%, with 10ppm of nanoparticles

it is 41.8% and with 20ppm of nanoparticles, 39.8% of original oil in

place was recovered. At low nanoparticles concentrations, the rate of

recovery of oil increases with an increase of nanoparticles

concentration and reaching a peak value at 20ppm, above which it starts

to decline.

Joonaki et al., [8] reported in his result, the total

oil recovery by using nanoparticles is 92.5%, 88.6% and 95.3% in the

three scenarios. This result indicates that the oil recovery will be

higher, and less amount of oil is remaining trapped within the porous

media, if the nano fluid injection begins earlier. In the experiment of

Pei et al., [9], 50% of the OOIP were recovered with silica

nanoparticles. These results demonstrate that the injection of

nanoparticles with polymer and surfactant system can significantly

increase the wettability, reduce the mobility ratio and thus leads to

the improvement of enhance oil recovery. Yousefvand et al., [10]

reported in his paper that the oil recovery factor after one pore volume

of the injected fluid has been obtained and results indicate that in

the presence of nano silica an improvement about 10% in the ultimate oil

recovery can be achieved and this is due to the viscosity enhancement

of the injected fluid. Also, nanoparticles have ability to change the

wettability to water-wet in some portions of the micro model.

In this study, we have organized a series of

experiments to know the potential effects of nano-materials on the

rheological behavior of polyacrylamide solution. The sample viscosities

in different concentrations of nanoparticles, shear rates,

temperature were measured. Because the viscosity plays a very

important role in enhance oil recovery. Also, this paper presents

a comparison between the effects of different nanoparticles on

the rheology of polyacrylamide in the presence of surfactants.

In addition, the viscoelasticity of polyacrylamide solution in the

presence of different nanoparticles was also measured.

Procedure

Materials

For this study, polyacrylamide (PAM) of molecular weight

150000, was purchased from Sigma Aldrich, U.S.A. CTAB

surfactant (≥99.0%, Merck, Germany) was used as received.

Gemini surfactants α,ω- bis (hexadecyldimethylammonium)

alkane dibromides (16-6-16 and 16-5-16) were prepared and

purified. Also, three types of nanoparticles were used for this

study. These nanoparticles are Silica fumes (particle size 0.007μm,

specific surface area 395 ± 25m2/g, density 36.8424649kg/m3),

TiO2 (particle size < 100nm, purity 99.5% trace metal basis,

specific surface area 50 -100nm) and Fe2O3 (particle size 50-

100nm, purity 97% trace metal basis, specific surface area 40-

60m2/g) was purchased from Sigma Aldrich, St. Lucia, U.S.A. All

the experiments were conducted at 50 °C and all the solution was

prepared in double distilled water (Table 1).

Preparation of solution

The polymer solution of 1.0wt% concentration was

prepared in distilled water. The nanoparticle of SiO2, TiO2,

Fe2O3 in a concentration of 0.2wt% to 1.0wt% was mixed with

polyacrylamide solution. After conducting several tests of polymer

and nanoparticle mixture, we add cationic surfactants with these

solutions. It is also observed that above 1.0wt% of a nanoparticle

of SiO2 and TiO2 (except Fe2O3), the solution of polymer and Gemini

surfactants gets precipitated. This will set the limit and we add the

nanoparticle at low concentration very carefully. The solutions of

polymer-surfactant-nanoparticle are not easily mixed with each

other and the solution will require a heating and agitation for

several hours.

Methods

There is a wide range of rheological measurement techniques

are available and each one has its advantages and disadvantages.

To maximize the value of the data generated it is obviously

important to ensure that the most appropriate technique is used

for the application. The shear viscosity of the prepared solution as

a function of shear rate and concentration were measured using

Anton Paar’s Modular Compact Rheometer (series 102) with

cone shaped measuring geometry at 50°C. The shear viscosity at

all solution concentrations, over a shear rate range of 0 to 500s-

1 was measured. The oscillatory frequency test was also carried

out at an angular frequency of 0.1 to 100 rad. s-1. Generally, the

oscillatory tests were carried out to determine the viscoelastic

behavior of the solution.

Core flooding experiment were performed to measure the

recovery of crude oil by using sand pack system. The crude oil

was obtained from Rajasthan oil field, India with API of 19.2 at

28 °C. The sandstone with the permeability of 2.5 milli Darcy and

porosity 0.19 was used for the test. During the test, the sand pack

was flooded with crude oil at 30psig. Then, the polymer-surfactant

and polymer-surfactant-nanoparticle solution was introduced in

a sand pack when water cut exceeded 95%.

Results and Discussion

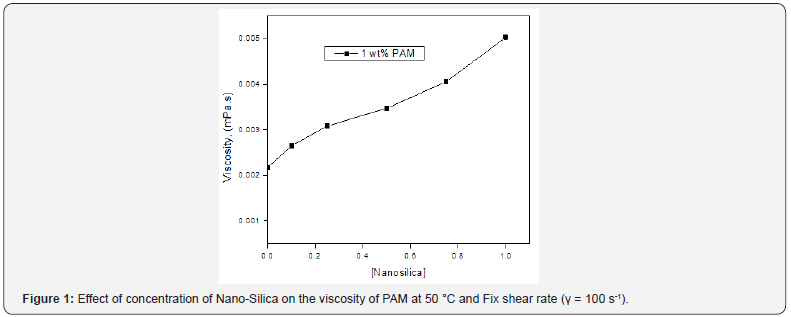

Effect of different concentration of nanoparticles on viscosity

The rheological properties of the injected fluid are an important

parameter in a chemical flooding process. The additional increase

in viscosity of injected fluid, the oil displacement efficiency is

increased, and more oil recovered from the porous rock. To

observe the effect of silica nanoparticles on the viscosity of

polymer solution, the viscosity measurement test was performed

with 1.0 wt.% of a polymer solution and also with polymersurfactants

system containing different silica concentration at 50

0C. From a Figure 1, the viscosity of polymer solution increases

with increase in a concentration of Nano-silica. The ion-dipole

interaction is developed between cations and oxygen atoms in

the tetrahedral structure of silica. Thus, the attack of cations to polymer molecules is reduced to some extent and the increase

in viscosity of the solution is observed in the presence of silica

nanoparticles. Consequently, the oil recovery increases during

chemical flooding test by increasing the silica nanoparticles

concentration [4].

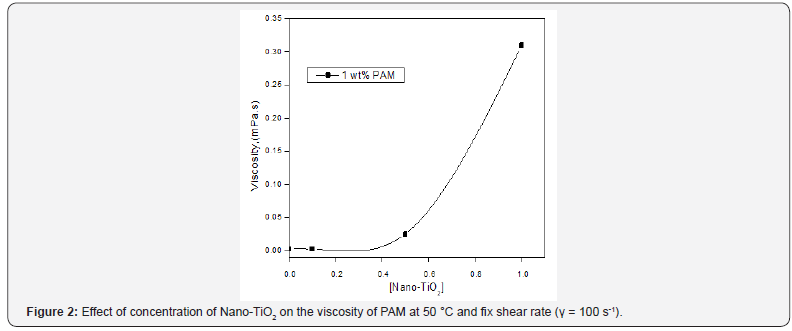

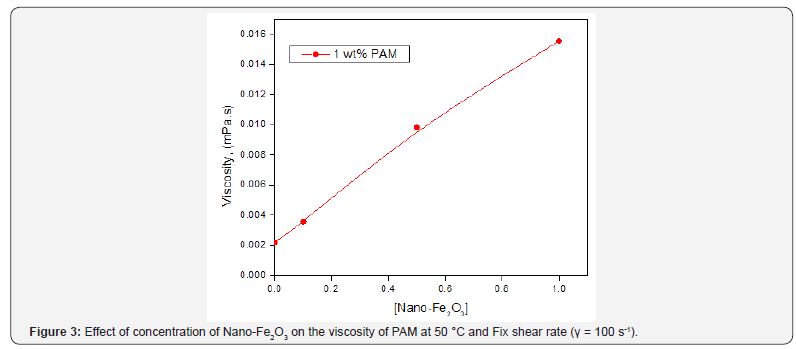

The same effect of nano-TiO2 and nano-Fe2O3 on the rheology

of polyacrylamide was also obtained at the same operating

conditions (Figure 2&3). The viscosity of the polymer increases

with increase in the concentration of nano-TiO2 and nano-Fe2O3

as expected. But there is a more drastic change in the viscosity

of polyacrylamide is observed with the nano- materials of metal

oxides. TiO2 shows the ability to provide much better result in

enhance oil recovery process while chemical flooding. Comparing

with the nano-silica, the nano- TiO2 increases the viscosity of

polymer solution up to 83.33% and the nano-Fe2O3 increases the

viscosity of about 64.28%. Also, some research studies suggested

that the reduction of oil viscosity is possible via nanoparticles of

metals oxide. A Bayat et al., [11] reported in his work, that SiO2,

TiO2, Al2O3 and nano-fluids flooding at 60 ͦC caused 8, 24 and 34%

viscosity reduction compared to the original oil viscosity at the

same temperature, respectively. This is because TiO2, Al2O3 and

Fe2O3 have higher thermal conductivity than SiO2.

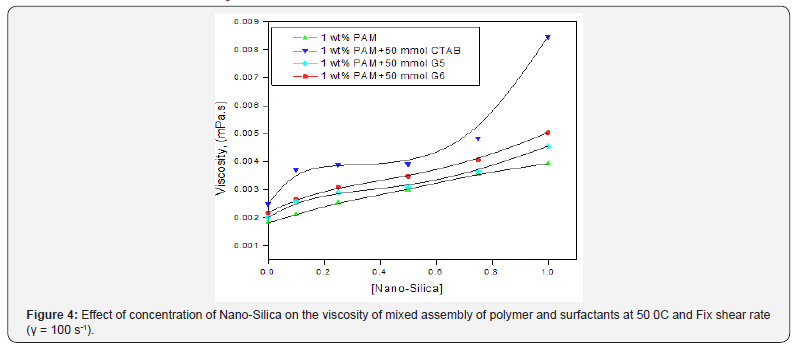

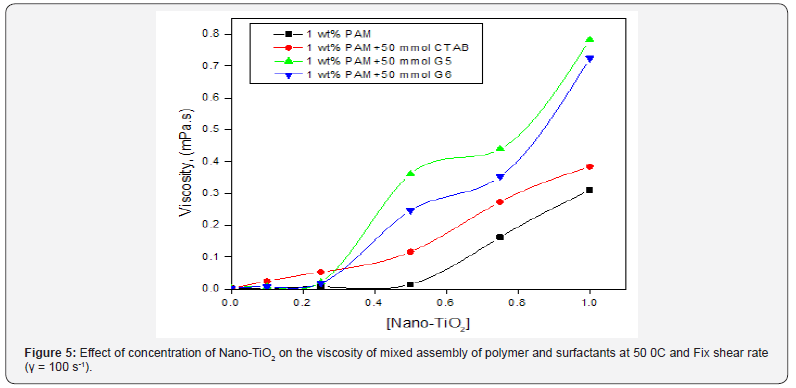

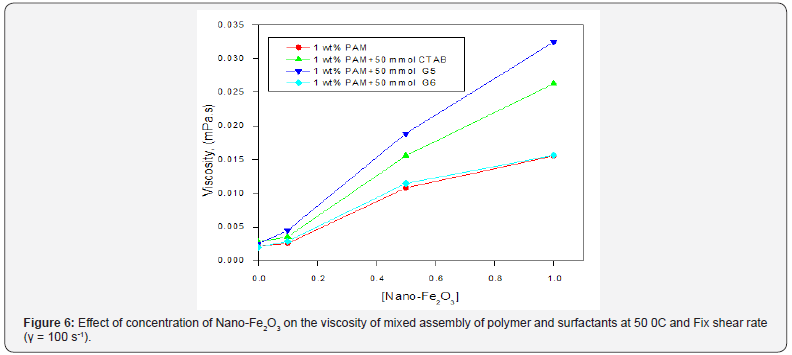

The effect of nanoparticles on the mixed assembly of polymer

and surfactant are shown in Figure 4,5 and 6. The concentration

of polymer and surfactants are fixed and the test was conducted at

50 0C. The shear viscosity of all the systems increases with nanosilica

concentration. As shown in Figure 4, the polymer solution

with CTAB surfactant shows a more drastic change in the viscosity

with a given Nano-silica concentration range. In a case of TiO2 and

Fe2O3, the Gemini (16-5-16) surfactant shows more effect on the

rheological property of polyacrylamide. The interaction between

the polymer and nanoparticles are affected by the presence of

a surfactant (Figure 5&6). The surfactants in the solution can

dislocate and relocate on the surface of the nanomaterial and

ultimately created new surfactant coated particles. This will lead

to increase in the viscosity of the solution.

Effect of shear on the rheological properties of the polymer-nanoparticles and polymer-surfactant-nanoparticles hybrid system

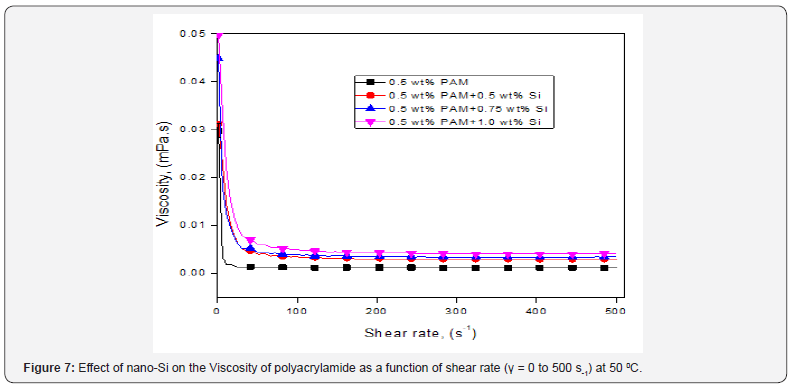

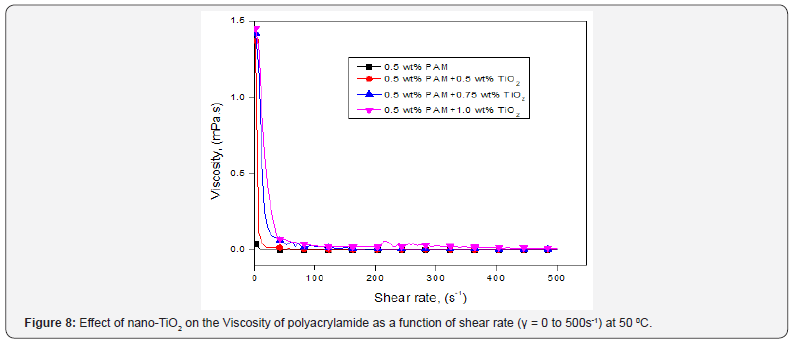

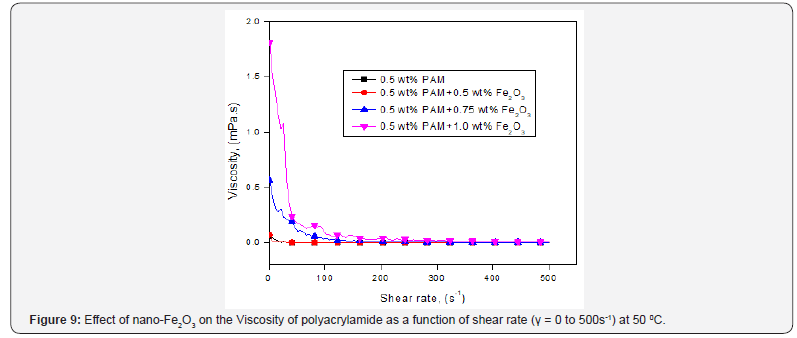

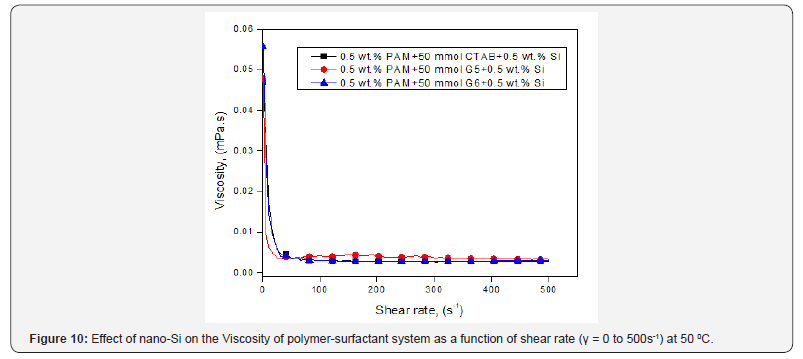

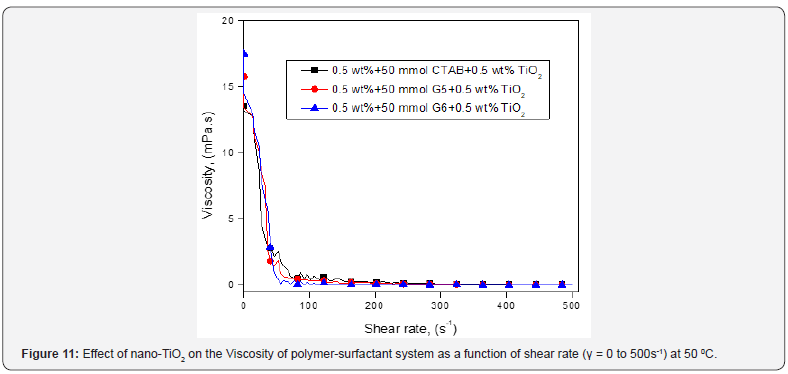

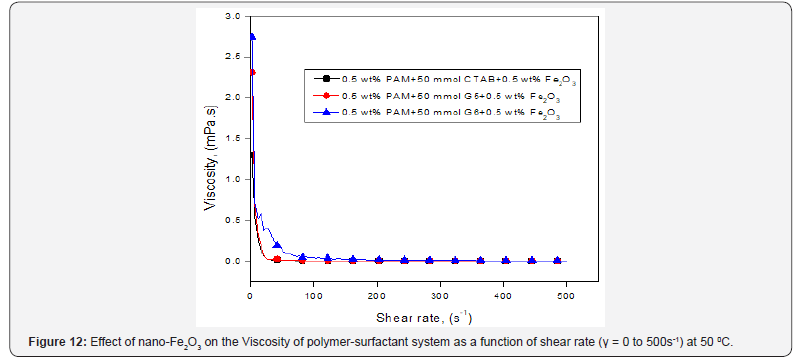

In this section, the effects of shear rate on the viscosity of

polymer-nanoparticles and polymer-surfactant-nanoparticles

hybrid system were studied. The results are plotted in Figure 7,

8 and 9 for a fixed PAM concentration of 0.5 wt.% with varying

concentration of nano-Si, nano-TiO2 and nano-Fe2O3 from 0.5 to

1.0 wt.%. The results indicate that the addition of nanoparticles in

the polyacrylamide solution leads to increase in viscosity. Because

of the irreversible adsorption of polyacrylamide on nanoparticles,

the resultant macro-molecular structure is stable and not easily

broken, and it leads to increase in viscosity of the system. The

viscosity of polymer-nanomaterial system is greater than the

viscosity of polyacrylamide solution at same temperature and

shear rate. Figure 10, 11 and 12 shows the viscosity variation of

polymer-surfactant-nanoparticles hybrid system. Across all the

polymer, surfactants and nanoparticles concentrations, it is found

that the samples revealed non-Newtonian shear thinning behavior

at low shear rate (γ < 25 s-1). But at high shear rate the solution

loses it’s non-Newtonian and shows shear thickening behavior

[12]. At low shear rate, the viscosity of the system is obviously

dropped. The bond between the polymer and nanoparticles are

not easily broken in normal state, but progressively weakens

as shear rate increases, thus the flow of the suspension is shear

thinning [13]. The shear thinning behavior and incremental shear

viscosity with concentration of polyacrylamide and nanoparticles

can be responsible for strong interaction between polymer and

nanoparticles.

On the basis of results, adding a small amount of nanoparticles

can improve the pseudo-plasticity behavior of polymer solution

at a given shear rate. From the above discussion, it is observed

that the nano-suspension increases the viscosity of the solution

in comparison to polymer viscosity. It indicates that the

nanoparticles can increase the sweep efficiency of the polymer

solution and oil recovery will be higher with nanoparticles. The

more nanoparticles transportation will be the more effective the

wettability alteration and better effective sweep efficiency of the

polymer-surfactant solution.

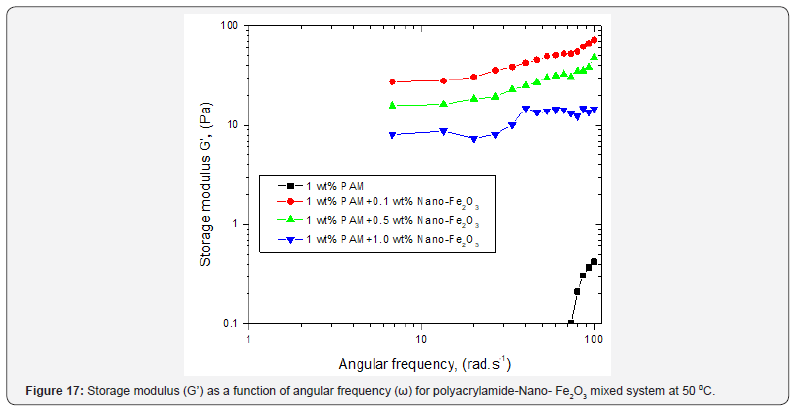

Effect of nanoparticles on viscoelastic behavior of polymer

The viscoelastic properties of polymer solution are widely

used to gain insight into structure strength of polymer in the

solution. The viscoelastic property of polymer plays an important

role in increasing the oil recovery. Larger the viscoelasticity,

greater will be the sweep efficiency of the polymer solution.

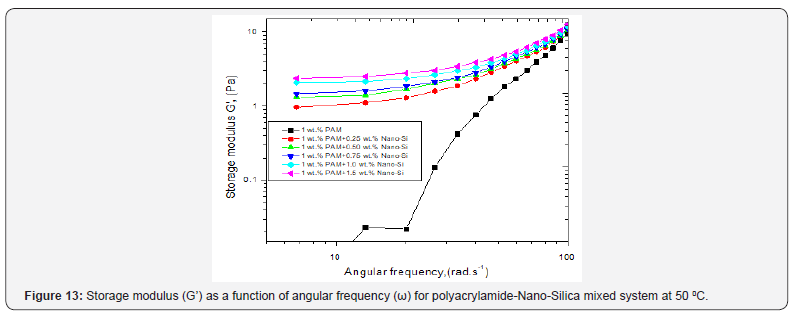

Figure 13 shows the plots of storage modulus (G’) as a function

of oscillatory angular frequency (ω) for polyacrylamide solution

and polymer-silica mixed system at 50 0C. For all the solutions,

storage modulus G’ is a strong function of angular frequency and

increases over the entire range. The elastic part of the polymer is

called the storage modulus (G’) and it is a measure of the energy

stored and recovered. The viscous part is called the loss modulus

G” which is a measure of the energy dissipated [14]. The value

of storage modulus increases with increases the concentration

of nanoparticles due to the more numbers of nanoparticles

available in the solution. With the addition of silica nanoparticles,

storage modulus of polymer-silica system greater than that of the

polyacrylamide solution. This indicates that the polyacrylamidenanosilica

mixed system undergoes microstructural changes and they have ability to increase the oil recovery. In the polymersilica

mixed system, the interaction between the amide group

of polyacrylamide and silanol functional group of nano-silica

occurred. So, the structure of polyacrylamide strengthened, and

the elasticity of the mixed system becomes more pronounced.

The elastic property is more dominant than the viscous i.e., G’ is

greater than G’’. This indicates that there is a significant buildup of

network structure that is responsible for imparting a significant

elasticity to the polymer solutions [12].

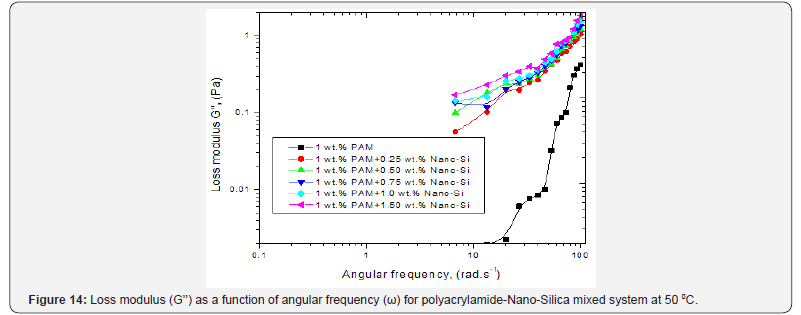

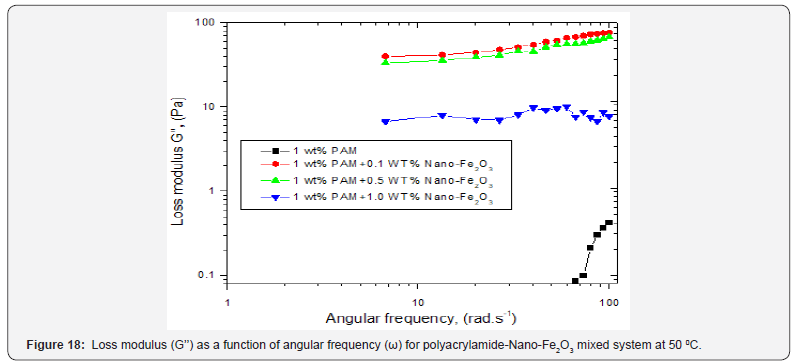

Figure 14 shows the loss modulus (G’’) as a function of

increasing angular frequency for PAM and PAM-silica mixed

system. The loss modulus (G’’) is the characteristic of the viscous

behaviors of the solution. When the value of storage modulus is

greater than the loss modulus, it represents the solution exhibits

viscoelastic gel like behavior and when the value of loss modulus

is greater than storage modulus, the system displays a liquid

like behavior. The value of G’ and G’’ increased with the angular

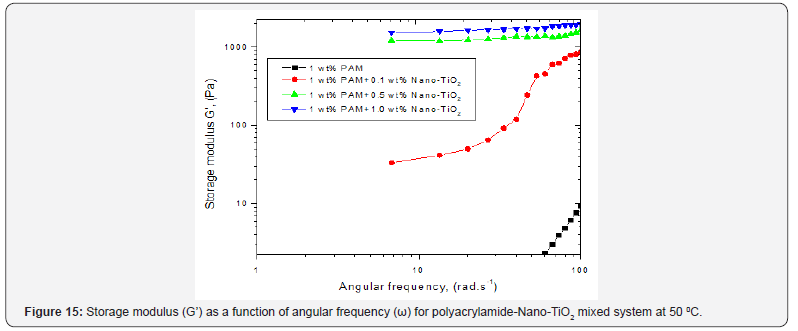

frequency. On comparing the viscoelastic effect of nano-silica on

polymer solution with TiO2 and Fe2O3 from Figure (15&17), the

storage modulus (G’) of TiO2 is much larger than that of nano-Si

and Fe2O3. G’ and G’’ increases with increase in a concentration

of nanoparticles. The increase in a concentration of nanoparticles

found to strengthen the network structure of polyacrylamide

solution and this leads to increase the viscoelastic properties.

At 1.0wt.% of TiO2, the flow curve is constant with the increase

of angular frequency and G’ > G’’, this means the elastic effect is

more dominant. The elastic behavior of all the above systems is

more than that of loss modulus because the decreased friction

at the polymer-nanoparticles interface led to the slight decrease

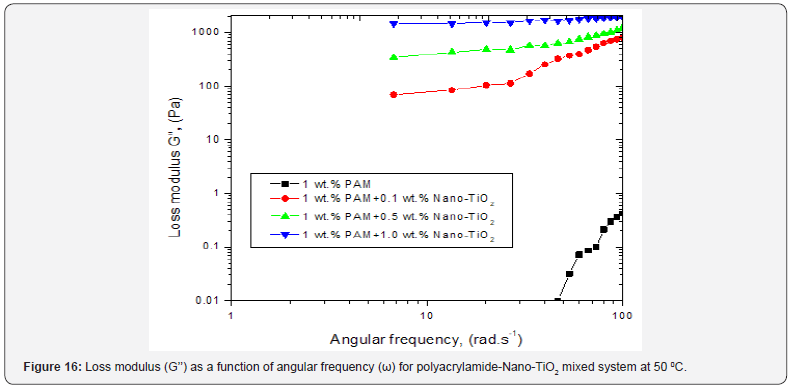

in the loss modulus. From (Figure 16 & 18), the loss modulus is

also increasing with the addition of nanoparticles, but the value

of loss modulus is slightly less than the storage modulus at all

concentration. Also, the value of loss modulus never exceeds to

zero [15].

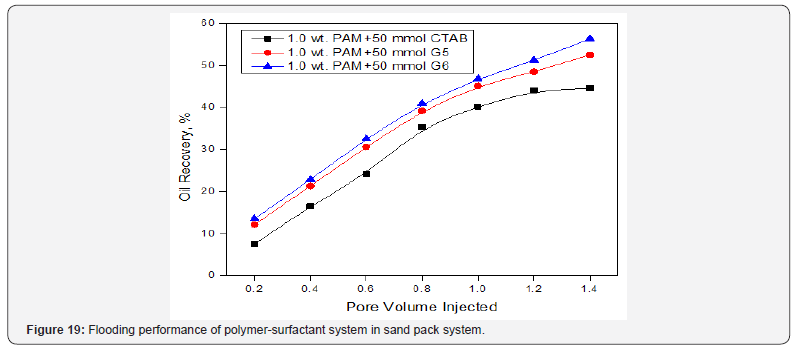

Core flooding Results

From Figure 19, the core flooding test was conducted by

injecting a polymer and surfactant solution. First, the sandstone

system saturated with the crude oil and then brine solution is

injected to measure the porosity. The porosity of the sandstone

system was found 0.19 or 19%. Then the crude oil was flooded

with 30psi pressure. Brine solution is then injected in a sand pack

system to displace the oil via secondary recovery and around 39%

of oil is recovered. After that the polymer and surfactant solution

were injected to recover the remaining oil as tertiary recovery.

Additional recovery of 5.5%, 13.5%, and 17.3% were obtained for

1.0wt. PAM+50mmol CTAB, 1.0wt. PAM+50mmol G5 and 1.0wt.

PAM+50 mmol G6 respectively. The polyacrylamide renders

the mobility to the oil rich phase by increasing the viscosity of

injected fluid. The crude oil droplets are mobilized by reducing the

interfacial tension between the oil-water interfaces. As the spaces

length of Gemini surfactant increases from 16-5-16 to 16-6-16,

the crude oil saturation increases due to improved coalescing of

mobilized crude oil droplets to form an oil bank and this result

in better oil displacement and hence greater oil recovery. In

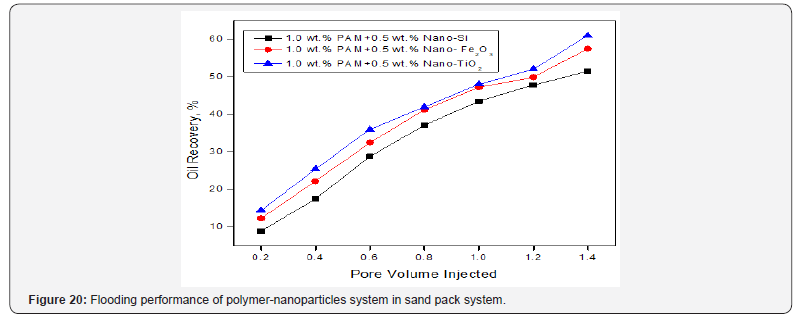

presence of nanoparticles, the oil recovery percentage is improved

as shown in Figure 20. The nanoparticles increase the viscosity

of polymer solution significantly and this will lead to increase in

storage modulus and loss modulus of polyacrylamide solution,

results in the oil recovery will increase. The nano titanium oxide

shows good result as compare to nano silica and nano iron oxide

material.

Conclusion

In the present study, the rheological behavior of

polyacrylamide and polymer-surfactant solution in the presence of

nanoparticles was examined. The result reveals that the presence

of nanoparticles strongly influences the rheological properties of

solutions. It is found that the shear viscosity of polyacrylamide

solution increased with the addition of nanoparticles. With the

introduction of nanoparticles in the polymer solution, the polymer

chains adsorb on the nanoparticles surface and complex micelle

type structure is formed and this interaction leads to increase the

viscosity, which indicates that increase in sweep efficiency. A non-

Newtonian shear thinning behavior was observed at low shear

rate (γ < 25s-1). The titanium oxide shows the promising prospects

for potential application in enhance oil recovery. The addition of

nanoparticles improves the viscoelastic properties of polymer. The

additional 11.5%, 17.5% and 22% of oil recovery were observed

in presence of nanoparticles. It means nano-suspension can be

used in enhance oil recovery and more beneficial than chemical

flooding without nanoparticles.

For more articles in Academic Journal of Polymer

Science please click on:

https://juniperpublishers.com/ajop/index.php

https://juniperpublishers.com/ajop/index.php

Comments

Post a Comment