Analysis of Non-Uniform Expansion Behavior of Injected EVA-Juniper Publishers

JUNIPER PUBLISHERS- Academic Journal of Polymer

Science

Abstract

Currently the sports footwear market is very

competitive, in which it is sought to produce products that provide high

performance, using technology in the production processes as well as in

the materials used. One of the main materials used in the composition

of soles and midsole of these products is EVA (Ethylene-Vinyl Acetate),

which brings several benefits such as cost reduction, comfort, lightness

and softness. The injection molding process is the most efficient for

obtaining EVA soles, however, EVA undergoes large expansions that may

vary according to its formulation and geometry of the desired model. The

objective of this work is to analyze the non-uniform deformation of

EVA, used in the injection molding processes, as well as one method used

to correct such distortions that occur in the expansion of this

material. For this, a bibliographic review was carried out to analyze

the chemical composition of the EVA, whose composition will determine

the characteristics of expansion and softness. The work also addresses

the steps of the injection process by analyzing the temperatures and

pressure employed and an analysis of how to predict and correct the

distortion in EVA expansion. It is proposed to use a section of a 3D

model, where it is determined where compensations should be applied and

using 3D modeling software.

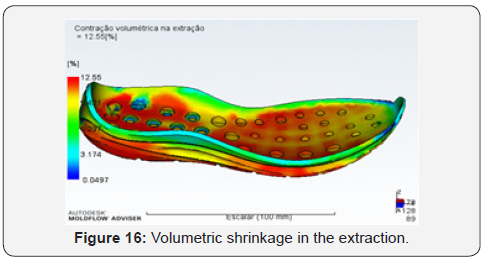

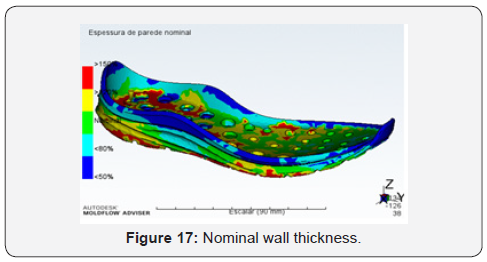

To analyze the generation of smaller bubbles in less

thick regions of an EVA sole, a scanning electron microscope (SEM)

analysis was performed. In addition, the measurements of the analyzed

model were compared with the virtual model through a 3D scan. Hardness

tests on the Asker C scale and injection simulations were also performed

to analyze the cooling time of the part after leaving the mold,

volumetric contraction that occurs in the extraction of the mold part,

and the thicknesses of the walls of the product. The results indicate

that the comparison of the models was within the accepted tolerance,

which allows a variation in the expansion of up to 1mm in the length of

the evaluated points. From the analyzes made in the scanning electron

microscope and in the hardness test, it was possible to verify that in

regions of smaller thickness and smaller volume, the EVA blend cannot

have its total expansion, i.e., micro bubbles of gases generated in the

expansion are smaller in these regions when compared to regions of

greater volume and thickness. Consequently, these regions become denser

and less soft. Simulations indicated that in regions where bubbles do

not expand, there is also an early cooling of the material when compared

to regions with higher volume, proving that the cooling time is

directly linked to the EVA expansion rate.

Keywords: EVA; IMEVA; Expansion; Midsole; Sole; Shoe; Footwear; Mold design; Mold injectionAbbrevations: EVA: Ethylene-Vinyl Acetate; SEM: Scanning Electron Microscope

Introduction

With increasing global competitiveness, the search

for new materials that provide higher-quality, better-designed products

that increase production efficiency are critical for companies that want

to stay competitive. Many manufacturers of sports shoes have adopted

EVA injected as the main component in soles and midsole, as this

material allows to make light, soft and cheap sneakers. However, the EVA

requires some care and some procedures must be adopted to obtain

injected parts of good quality. EVA has the capacity to expand from 30%

to 90% its size and there is great difficulty in predicting how this

expansion occurs due to non-uniformity in the expansion process.

This article analyzes the non-uniform behavior of EVA

expansion and some methods used to correct this deformation.

Through years of experience and with the aid of 3D modeling

software, compensations are applied at certain points of the product,

according to the geometry, to try to predict the behavior of the

material. In order to obtain the EVA (Ethylene-Vinyl Acetate) that is

molded in the injection process, it is necessary to make a mixture to

acquire a compound that will determine the characteristics of expansion

and softness of the material, for the formulation of the compound we can

have the following types of raw materials [1]:

a. Resins: It is the base of the blend. Generally,

the EVA resin is mixed with LDPE and elastomers depending on the

desirable properties;

b. Expanders: These are organic or inorganic compounds that, by the action of heat, decompose to generate solid and

gaseous byproducts of diverse nature, thus being responsible

for the expansion process;

c. Activators: They are catalysts, decrease the decomposition

temperature of the blowing agent, thus avoiding the

degradation of the polymer matrix;

d. Cross-linking agents: They are responsible for forming

crosslinks in the polymer, increasing dimensional stability,

chemical resistance, heat stability, and stiffness of the

compound;

e. Lubricants: They are substances that decrease the friction

between the polymer chains facilitating the processing and

decreasing any interaction of the polymer mass with the

equipment used;

f. Plasticizers: These are liquid substances with high boiling

points and low molecular weight. When added to a polymer,

they increase the flexibility and softness of the product. In

the processing of EVA foams the aromatic plasticizers are the

most used;

g. Pigments: Organic and inorganic compounds responsible

for coloring the foams, influence the expansion of the

material. In EVA you can pigment with different colors.

h. Loads: These are insoluble solids which are added to

the polymers during processing in amounts sufficient to

decrease the final cost or to change some of their physical

properties in a controlled manner.

Eva Injection Molding Process

After blending to form the EVA compound for injection

is completed, the material is taken to an injector that can be

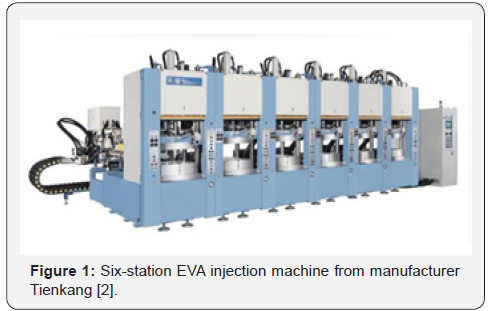

rotating or with stations aligned according to Figure 1. The

justification for adopting a machine with many stations is given

by the fact of the average injection cycle of each mold is high,

around 7 minutes, so with a multi-station machine you can

achieve a faster and more efficient production.

Below the steps of the injection process [3]:

(a) The mixture is added to the injector storage tank.

(b) The injection volume is calculated and adjusted according

to the mold.

(c) The material is heated to 95 °C and injected into the mold

at a pressure of ~1200bar.

(d) The mold is heated to 170 °C to activate the expander and

also the crosslinking agents

(e) The mold is kept closed at 170 °C until the crosslinks are

fully completed, about 1.5min / mm thick

(f) The mold is opened, and the EVA sole jumps out of the

cavity rapidly and begins to expand.

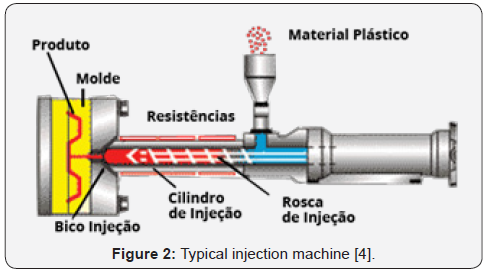

Injection in a typical injection machine can be observed in

Figure 2. In order to obtain an EVA midsole or midsole injected

into the appropriate dimensions, we must follow a few steps,

where through experience in this type of product, we know in

which points we should apply the compensations to correct the

subsequent distortion in the EVA expansion.

First, we must have our 3D model defined, from there we

follow the next steps:

• To demonstrate the steps, we will use a section of an

example 3D model, as in Figure 3.

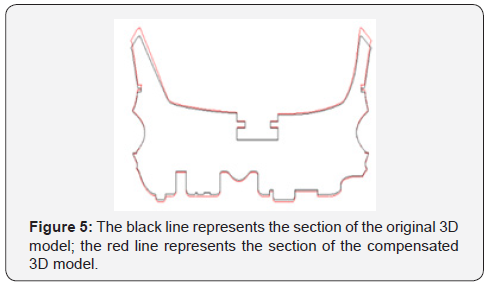

• The 3D modeling software called Rhinoceros [5],

geometry deformation tools were used to compensate for the

points of interest (Figure 4 &5).

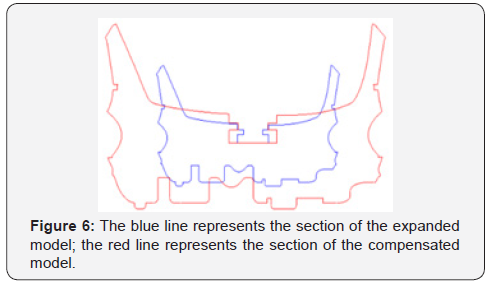

After the compensations, the general expansion factor was

applied, which is reprinted in Figure 6 by the blue line, which

can vary from 30% to 90%, depending on the formulation of the

EVA blend, this factor was applied reducing the size of the model.

After the compensions o and the general expansion factor

were applied, as it was a model for aluminum casting, a further

1.2% was also applied to compensate the contraction of the

aluminum. If it were a completely milled mold, there was no

need to compensate for the shrinkage of the aluminum.

Analysis and Results

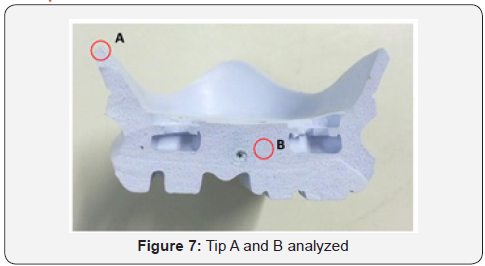

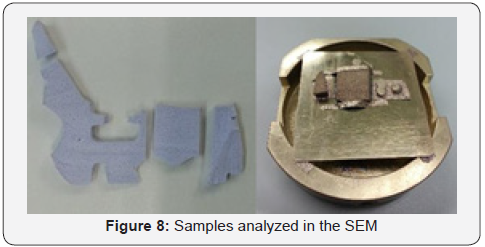

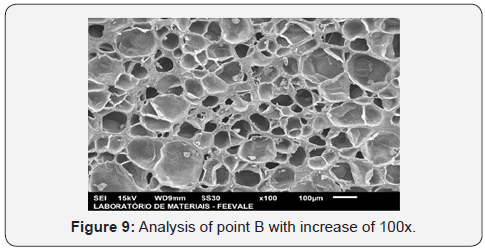

To verify the generation of smaller bubbles in less thick

regions, a cross section was cut from an eva sole, so an analysis

can be performed in the electron scanning microscope (SEM) of

Feevale University, comparing images at points A and B (Figure

7&8) of the same product, with increases of 50x and 100x. Figure

9 shows the analysis at point B, made in SEM with a 100-fold

increase, we can clearly observe the formation of larger bubbles

when compared to Figure 10, which represents point A and this

with the same increase of 100times.

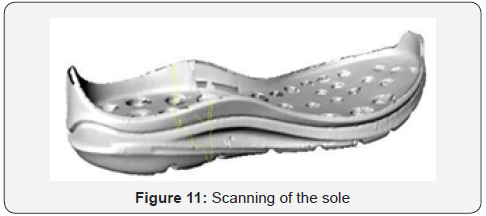

To verify if the analyzed model reached the desired

measurements, the original virtual model was compared with a

3D scanning, this was done in a 3D scanner, model Infinite 2.0, of

the manufacturer Cimcore (Figure 11&12) [6].

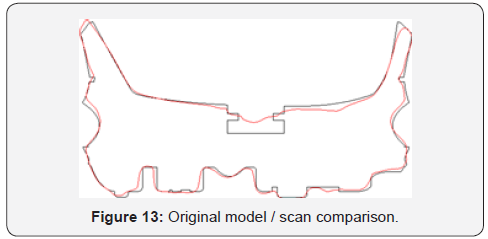

The result of the comparison of the models was within the

accepted tolerance, which allows a variation in the expansion

of up to 1mm in the length of the points in question. This comparison can be seen in Figure 13, where the black line

represents the original 3D mole and the red line represents a

scan of the injected EVA sole.

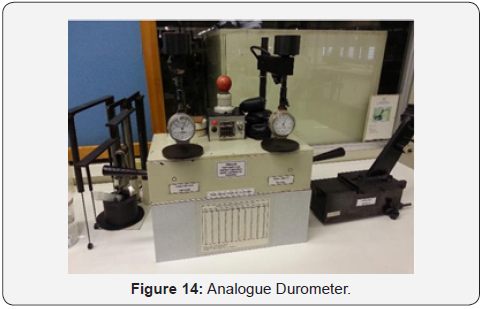

Also, for points A and B were made hardness tests using

the Asker C (A/C) scale, with an analogue durometer and 5mm

spherical tip (Figure 14). For comparison purposes, the two

samples were prepared with 3mm thickness and an average of

3 results were made. The average hardness found at point A was

58 A/C and at point B was 44 A/C

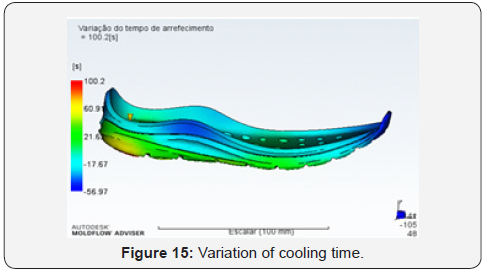

Injection simulations were performed in Autodesk Moldflow

Adviser software [7], where it was possible to perform several

analyzes, such as:

a. Variation of the cooling time of the part after leaving

the mold, Figure 15.

b. Volumetric contraction occurring in the extraction of

the mold part, Figure 16.

c. Thickness of the product walls, Figure 17.

Final Considerations

From the analyzes made in the scanning electron microscope

and in the hardness test, it was possible to prove that in regions

of smaller thickness and lower volume the EVA blender expander

cannot have its total expansion, that is, the micro bubbles of

gases generated at the moment of expansion are smaller in these

regions when compared with regions of greater volume and

thickness, consequently these regions become denser and less

tender. This directly influences the final geometry of the product Figure 18. The compensation methods to correct the distortion

of the EVA parts work satisfactorily within the tolerance,

however they cannot predict all cases of distortions, since the

models generally present varied and complex forms. Simulations

done in Autodesk Moldflow Adviser [7], demonstrated that in

these regions where the bubbles do not expand, there is also

an early cooling of the material, when compared to regions of

higher volume, thus proving that the cooling time of the material

is directly linked to the EVA expansion rate.

Comments

Post a Comment