Energy Potential of Natural, Synthetic Polymers and Waste Materials - A Review-Juniper Publishers

Authored by Michael Ioelovich

Abstract

In this paper, the energy potential of natural

(polysaccharides, lignin, etc.), and synthetic polymers (polyolefins,

etc.), polymer materials (plant biomass, plastics and their solid

waste), as well as combustible liquids and gases derived from them has

been studied. To determine calorific values of solid, liquid and gaseous

substances, various experimental and calculation methods were used. For

this purpose, improved equations based on chemical structure and

elemental analysis was proposed. It was shown that the conversion of

solid materials into liquids or gases reduces the yield of thermal

energy. Therefore for the production of thermal energy, it is more

profitable to burn the solid biomass or plastic than combustible liquids

and gases, derived from them. Studies have shown that lipids and lignin

increase, whereas moisture and ash reduce the calorific value of

biomass. The calorific value of most synthetic polymers and plastics is

higher than that of biomass samples, but resources of waste plastics are

about 10 times lower than these of biomass. The use of compacted

mixture of biomass and plastic waste enables to obtain solid fuels with

unique properties, such as increased calorific value and energy density,

as well as reduced emission of carbon dioxide. Considering the total

amount of biomass and plastics waste destined for combustion, it was

calculated that current annual energy potential of the waste materials

is about 145 EJ. The increase the share of biomass in the production of

alternative energy can simultaneously contribute to reducing in

greenhouse gas emission and improving the ecological state of the

environment.

Keywords:

Plant polymers; Biomass; Synthetic polymers; Plastics; Solid waste;

Solid fuel; Liquid fuel; Gaseous fuel; Calorific value; Energy density;

Energetic potential

Introduction

The supply of sustainable energy is the basis of

modern civilization. Nowadays, the main energy sources are fossil fuels,

coal, petroleum and natural gas, which cover up to 80% of global energy

consumption [1]. However, the use of fossil fuels causes the emission

of large volumes of greenhouse gas - carbon dioxide, in the amount of

1600-1800m3 per ton of fuel. The further intensive energy consumption

can leads to irrevocable depletion of reserves of these fuels. Therefore

in recent years a considerable attention has been paid to plant biomass

as inexpensive and inexhaustible source of renewable energy [2].

The term “biomass” means here a variety of plant

materials, as well as their residues and wastes [3]. Total resources of

such biomass reach 1.5 trillion tons and increase by 200-250 billion

tons annually as a result of the photo- and biosynthesis [4]. The main

structural constituents of plant biomass are three natural polymers, and

namely cellulose, hemicelluloses, and lignin. Being the most abundant

organic matter on Earth, cellulose forms the skeleton of cell walls of

various plants. The content of cellulose in herbaceous plants is 30 to

40%, in woods 45 to 50%, in best plants (flax, ramie, jute, etc.) 60 to

70%, and in cotton fibers upwards of 90% [5].

Cellulose is a natural semi crystalline

polysaccharide having long linear chains consisting of repeat

anhydroglucose units in a “chair” conformation [6]. The linear

macromolecules joined by hydrogen bonds form super molecular structure

of cellulose that consists of thread-like elementary nanofibrils and

their bundles called micro fibrils. Within the elementary fibrils,

ordered crystallites and disordered non-crystalline domains (DD) are

present. During the process of isolation and modification of cellulose,

the cleavage of glycosidic bonds in DD occurs, which leads to partial

depolymerization of this polysaccharide. Hemicelluloses are

non-cellulose polysaccharides comprising of pentosans and hexosans [1].

The content of these components in various plants is 20 to 40%.

Hemicelluloses are hydrophilic amorphous heteropolymers. The chemical

structure of hemicelluloses consists of chains of a variety of

acetylated links of pentoses or hexoses and backbones [7]. In the plant

cells, hemicelluloses are binders between fibrils of cellulose and

lignin.

Lignin is a rigid, aromatic, amorphous and

hydrophobic polymer that is stable to some chemical reagents and

cellulolytic enzymes [7]. The content of lignin in plant biomass ranges

from 10% for corn cob or rice straw to 48% for olive husk [8,9]. Lignin

is a complex polymer of phenylpropane units, which are cross-linked

to each other with a variety of different chemical bonds [10]. In the

lignified plant biomass, one portion of lignin is localized between

the cells, while another portion of lignin is localized inside the cell

wall in the form of thin hydrophobic nano-layers. The cellulose

nanofibrils inside the plant cell wall are separated from each

other by means of the thin layers of amorphous hemicelluloses,

whereas fibrillar bundles consisting of the nanofibrils of cellulose

and hemicelluloses are surrounded with hydrophobic nano-layers

of lignin, which protect the hydrophilic polysaccharides against

biological and chemical attack [11].

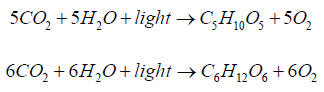

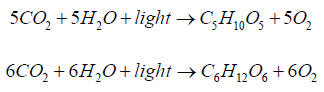

Polymeric constituents of biomass are formed in nature by

photosynthesis absorbing the solar energy. At first, monomeric

sugars are synthesized in chlorophyll pigment of plant leaves from

carbon dioxide and water absorbing quanta of red and blue-violet

light [12,13]. Photosynthesis is a complex, multistage process that

is proceeding in two phases - light and the dark. The light phase

occurs in the presence of light in the thylakoid membranes of

chlorophyll, with the participation of electron transfer proteins,

specific carrier NADP and ATP-synthase, the result of which is

photolysis of water molecules, binding of formed hydrogen by

NADP and release of oxygen. The dark phase proceeds without

light with use of NADP • 2 H complex and carbon dioxide and their

transformation to monomeric sugar with the participation of ATP.

Summary process of photosynthesis of monomeric 5 C - and 6 C

-sugars can be described as follows:

At biosynthesis of cellulose and starch, glucose is used as

C6-monomer in polycondensation reaction with formation of

long polymeric chains. Cellulose of plants is formed on the

surface of plasma membranes of living cells using a terminal

enzymatic complex shaped as a nano-rosette with a hole in the

middle [14,15]. At biosynthesis of hemicelluloses, hexosans

and pentosans, photo-synthesized hexoses (e.g. mannose) and

pentoses (e.g. xylose) participate in polycondensation reactions.

The photo-synthesized sugars are probably the precursors of

lignin biosynthesis in the plant cell walls [16,17]. In the process

of biochemical reactions these sugars form a series of aromatic

acids, aldehydes and alcohols, which are then polymerized into

lignin.

In fact, biomass can be considered an accumulator of solar

energy captured during photosynthesis. To generate the heat

energy the plant biomass is burned, resulting in the release of

accumulated solar energy. Various biomasses and plant-based

materials can be used as solid fuels such as wood (e.g. firewood,

pellets), herbaceous plants (e.g. Miscanthus, Switch grass,

Bermuda grass, etc.), forest residues (e.g. sawdust, twigs, shrubs,

etc.), residues of agricultural plants (e.g. stalks, husks, cobs, etc.),

residues and wastes of textile, pulp, paper and cardboard, as well

as algae biomass. Energy is also obtained by burning of refuse,

containing waste paper, cardboard, textile, wood and other plant

waste. In many countries, these bio-resources account for over

90% of household energy consumption [18].

A specific feature of plant biomass is that this solid biofuel is

neutral for emission of carbon dioxide, since its burning produces

the same amount of this green house gas as it was absorbed from

the atmosphere during biosynthesis. Furthermore, the biomass

can be used also as feedstock for production of liquid and gaseous

biofuels. Currently, plant biomass is the fourth largest energy

source after fossil fuels [19]. Moreover, it is the largest source of

renewable and alternative energy sources, far ahead of solar, wind

and nuclear power stations, as well as hydroelectric and some

other power stations [20,21].

An additional energy source can be waste of synthetic

polymers and plastics. At present, polymeric materials are widely

used for the production of packaging materials, consumer goods

and diverse industrial products. Every year in the world about

250-300 million tons of plastics are produced [22]. However after

usage, these biostable polymer products are thrown away and

pollute the environment. A huge problem is also the pollution of

water bodies and oceans with polymer debris [23]. The cardinal

way of eliminating biostable plastic debris is burning, which

allows also generating an additional thermal energy.

Thereby, the main purpose of this review was to evaluate the

energy potential of natural and synthetic polymers and materials

such as plant biomass, plastics and their solid waste, as well as

combustible liquids and gases derived from them, in order to use

them in energy production

Thermochemistry of Fuels

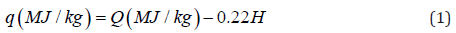

The specific heat energy or calorific value of solid fuels or

organic matters can be expressed by higher heating value (HHV) and

lower heating value (LHV) also called net combustion heat (NCH).

The HHV has the same meaning as the enthalpy of combustion,

which assumes a return of temperature to the standard value; in

this case the water vapor produced by combustion is condensed to

a liquid, hence yielding its condensation heat [24-26]. As opposed

to HHV, the LHV or NCH assumes that water remains in vapor

state at the end of combustion process [27-29]. Thus, the LHV or

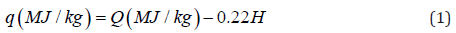

NCH characterizes the actual combustion process. The following

notations were used to simplify the symbols: HHV=Q and LHV

(NCH) =q. These characteristics of calorific value are connected to

each other by the relationship [30]:

Where,

H is percentage of hydrogen in a sample

To study the calorific value of solid fuels or organic

matters various methods can be used. The first is experimental

determination of HHV, which is performed by combustion of organic sample in a special device, bomb calorimeter [31-34].

The calorimetric experiment can be briefly described, as follows.

The small sample (1g) is put into special container of calorimetric

bomb, which is filled with moist oxygen under increased pressure.

The bomb is closed and put into isothermal water calorimeter.

The system is thermo stated at 298.15K to achieve an equilibrium

state. After ignition of the sample, the temperature rise ( Δ T) is

measured. The higher heat of combustion is calculated from

equation:

where m is mass of the dry sample , C is value of energy

equivalent of the bomb calorimeter determined by burning of

standard benzoic acid; e1 and e2 is correction for ignition energy

and possible formation and dissolutions of acids (sulphuric

or/and nitric) from trace S or/and N elements of the sample,

respectively.

However, the bomb calorimeter is a complex, expensive

and not always available device. In addition, the measurement

of calorific value is lengthy and requires multiple repetitions to

obtain a reliable result.

Other method is based on Hess’s law, according to which the

combustion enthalpy at standard conditions can be calculated

from difference between formation enthalpies of combustion

products ( Δf Hpi ) and formation enthalpy of the combustible

matter ( Δf Ho ):

Wherein i is number of moles of various products of

combustion, i.e. CO2, H2O, SO2, etc

Consider, for example, burning process of cellulose:

C6 H10 O2 + 6O2 →6CO2 + 5H2 O

It can be found from thermodynamic handbook that

Δf Hp co2 = −393.51 KJ mol , Δf Hp H2o = − 285.83KJ mol

and Δf Ho2 = 0. Standard formation enthalpy of cellulose

is, on average: Δf Ho = − 965KJ mol [34,35]. Then, the

combustion enthalpy of cellulose can be calculated by eq. (2):

Δc H = (6X 393.51) -(5 X285.83) -965=- 2825( KJ/ mol)

. Thus, HHV of cellulose sample:

Q ≈ −Δc H = 2825KJ /mol17.4 MJ kg , and q =16.1MJ / KG .

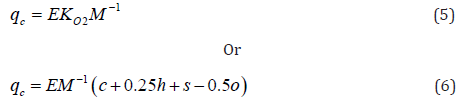

Third method is based on the combustion process of organic

matter:

Cc Hh Oo Ss Nn+Ko2 O2 →cCO2 + (h/2 )H2 O + sSO2+(n/2)N2

Where KO2 is consumption of oxygen (moles per 1 mol of

the matter); c, h, o, s, n is number of the corresponding atoms

in molecule of low-molecular substance or in repeating unit of

polymer.

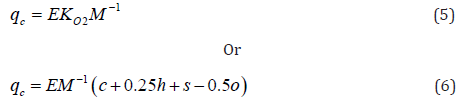

As it is follows from the combustion reaction,

According to hypothesis proposed in [36,37], a net combustion

heat (NCH) of organic matter is directly proportional to oxygen

consumption, i.e.:

Where E ≈ 418KJ / mole 2 O is energetic parameter; M is

molecular weight of low-molecular substance or repeating unit

of polymer

By finding the KO2

value or

number of the atoms c, h, o and s

from combustion reaction, it can easily to calculate the net heating

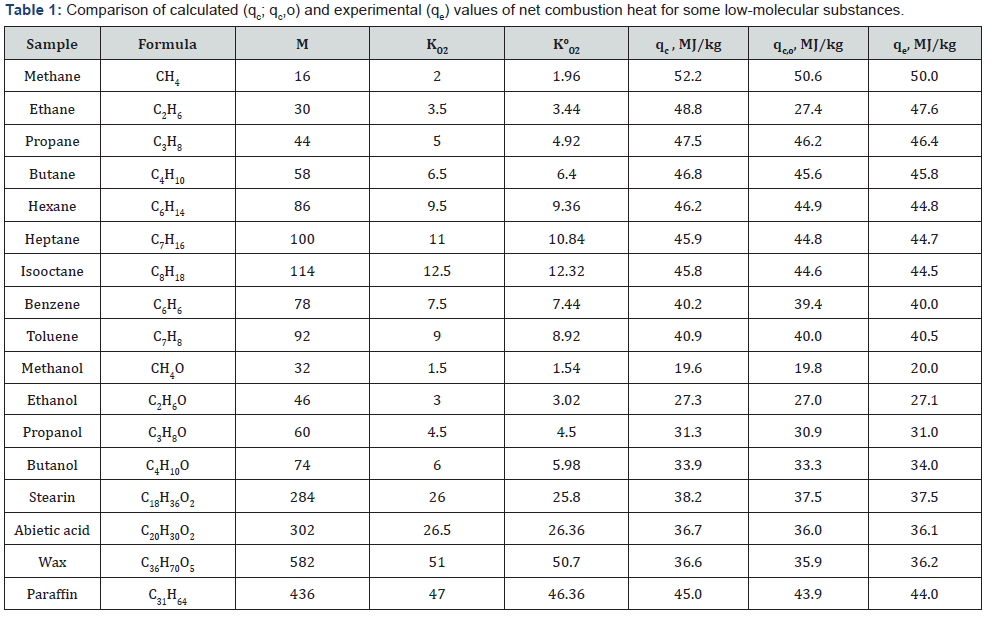

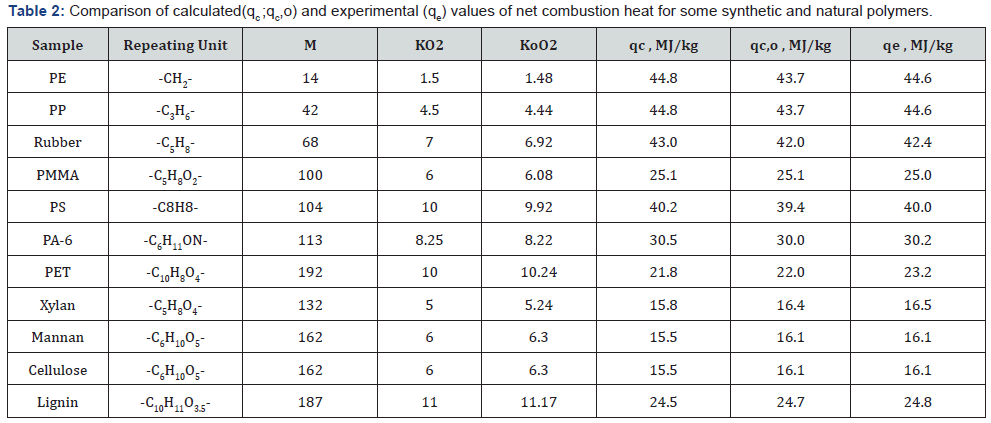

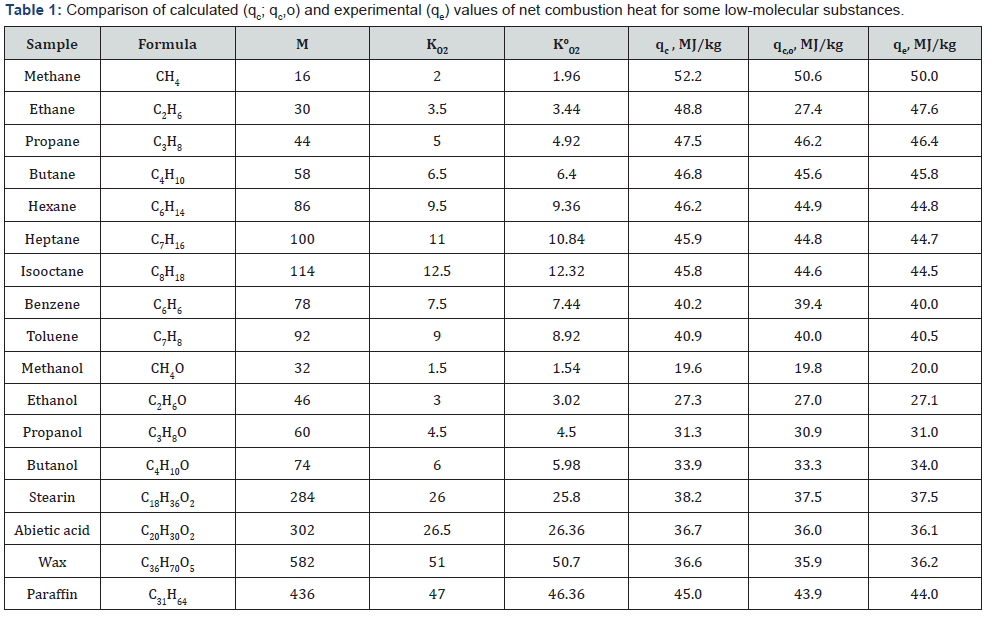

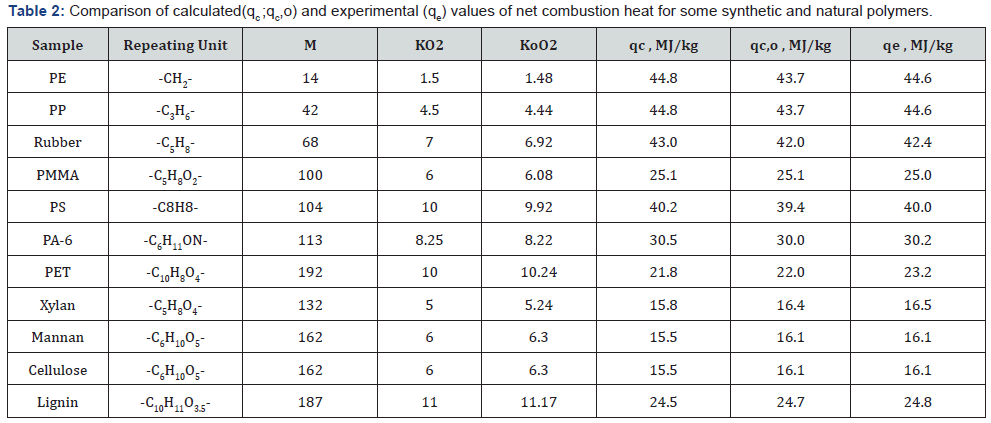

value of organic matter by eq. (4) or (5).The results showed that

the calculated values differ from experimental values of NCH

within ±6%. (Table 1 & 2).

In the case when it is necessary to find the HHV, the following

equation can be used:

To reduce the divergence between the calculated and

experimental values, several corrections were introduced in eq.

(4), (5) and (6). As a result, the following improved equations

were derived [38]:

Where E° = 413kJ/mole 2 O is corrected energetic parameter;

KO2° is corrected parameter of oxygen consumption.

The improved equations permit to reduce the discrepancy

between calculated and experimental values to ±1% (Table 1 &

2).

In addition, it is necessary to mention a few correlation

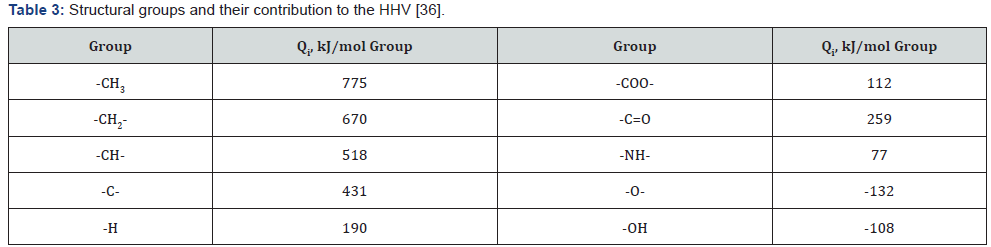

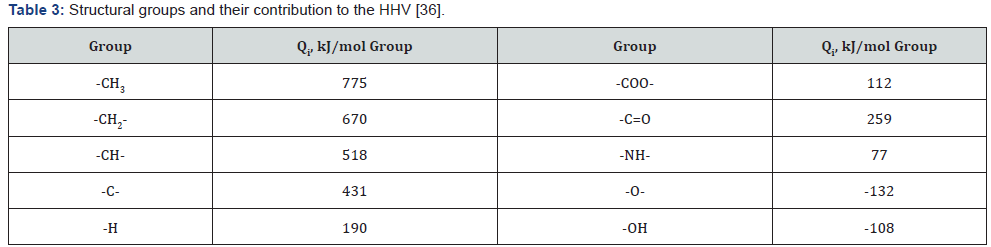

methods. One from them is based on the contribution of structural

groups to the HHV [36] (Table 3). HHV of the sample was calculated

by the equation:

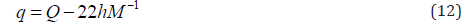

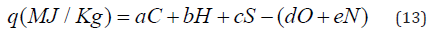

Then, the NCH of the sample can be calculated from eq. (1)

or (12).

The verification showed that the method of contribution of

structural groups makes it possible to predict the heating value of

various organic substances and polymers with accuracy of ±5%.

Other correlation methods are based on the determination of

percentage of C, H, O, S and N atoms in molecule of low-molecular

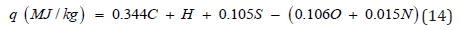

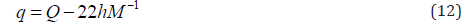

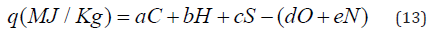

substance or in repeating unit of polymer:

Where a, b, c, d, e – coefficients; C, H, O, S and N are percentage

of corresponds atoms calculating from formula of the organic

substance.

In the known equation of Mendeleev [39,40] a=0.339, b=1.035,

c=0.109, d=0.109 and e=0.015. Parikh et al. [41] proposed other

coefficients of eq. (12): a=0.349, b=0.960, c=0.101, d=0.103 and

e=0.015. Study have shown that the equation of Mendeleev gives

depressed values (-5%), whereas the equation of Parikh gives

overestimated results (+5%) in comparison with experimental

values of NCH. To increase the accuracy of calculations the

corrected coefficients were proposed [42]: a=0.344, b=1.000,

c=0.105, d=0.106 and e=0.015.

As a result, the difference between calculated and experimental

values can be reduced to ±1% (Table 4).

Thus, the best results give calculations by the equations (10)

and (14).

Energy Potential of Solid Polymer Materials and their Waste

As is known, about 200-250 billion tons of biomass are

created annually as a result of photosynthesis. Since biomass uses

only 1% of the incident solar irradiation, then total amount of

solar energy needed to create 200-250 billion tons of biomass can

be estimated at 300-400ZJ, whereas amount of accumulated solar

energy at 3000-4000EJ.

Most of the created biomass amount, 90%, is decomposed in

nature, and about 45-50% of the remaining biomass (wood, bast

plants, cotton, cereals, technical crops, etc.) are used in industry

and agriculture. Thus, the amount of unused biomass is about 10-

15 billion tons, which can be used as a source of alternative energy

[1,2].

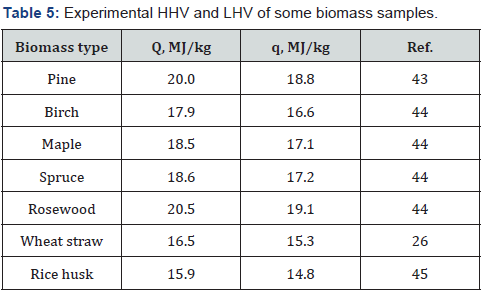

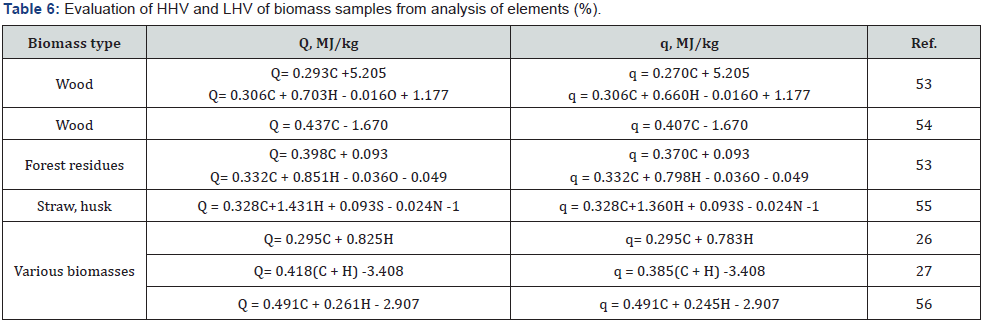

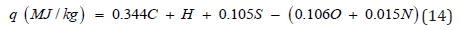

The use of biomass as a solid fuel requires knowledge of its

specific thermal energy, called also calorific value. Therefore,

numerous attempts have been made to determine the calorific

value of various types of biomass. Some of these studies have been

performed with the use of precise calorimetric technique [43-45]

(Table 5). The problem is that this technique is expensive and not

always available; besides, direct measurements are complex and

long. For this reason diverse express methods were developed

to calculate the calorific value of various plant biomass. These

methods are based on preliminary elemental and proximate

analysis and well as determination of chemical composition,

study structural characteristics and various properties of biomass

samples [46-50].

In contrast to plant polymers, the elemental composition of

such complex composite as biomass cannot be calculated from

chemical formula. Therefore, various experimental techniques

(e.g. gas analyzer, etc.) are applied to determine the percentage

of various elements in the plant materials. Proximate analysis of

biomass allows determining the content of ash, volatile matter

(VM), fixed carbon (FC). Standard methods of chemical analysis

are known to determine percentage of cellulose, hemicelluloses, lignin and some other components, such as starch, pectin,

proteins, extractives, etc. For example, the content of cellulose and

hemicelluloses in biomass can be determined using the standard

method NREL LAP-002, acid-insoluble lignin using the NREL LAP-

003, acid-soluble lignin using the NREL LAP-004, ash using the

standard method NREL LAP-005 and extractives using the NREL

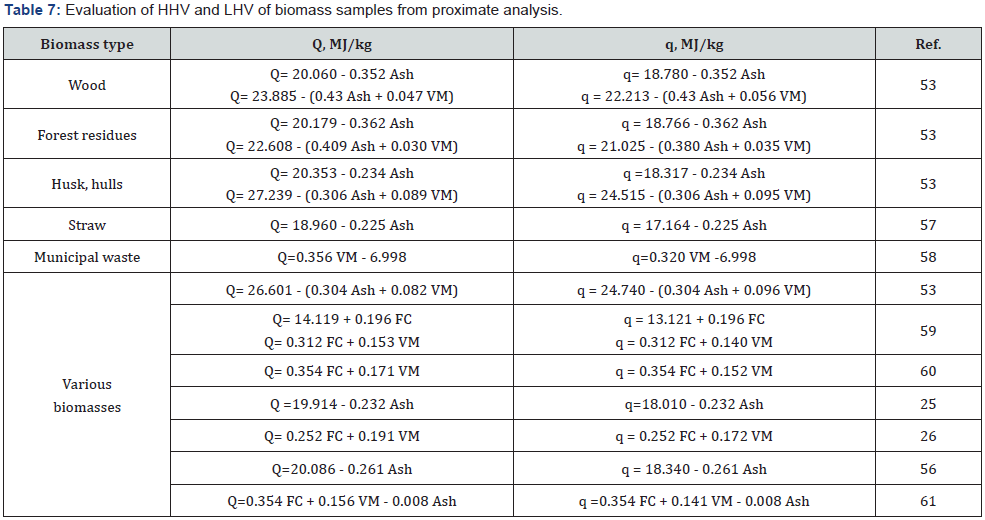

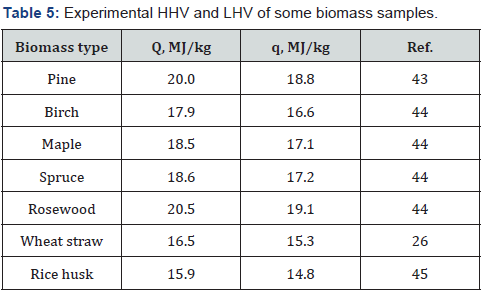

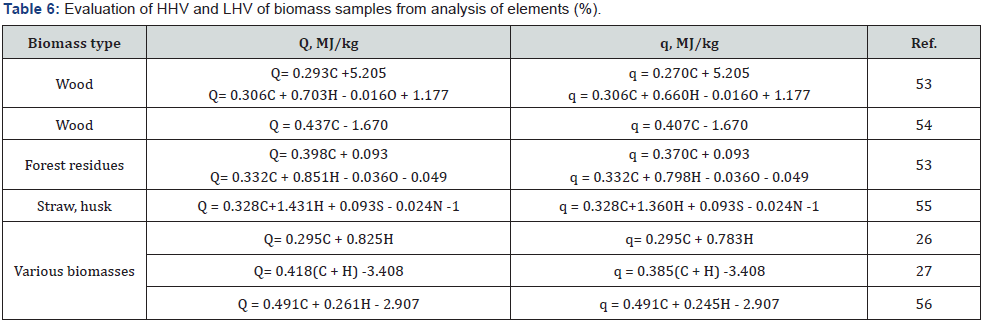

LAP-010 [51,52]. Some correlation equations for estimating the

HHV and LHV of different biomass types are presented in (Table

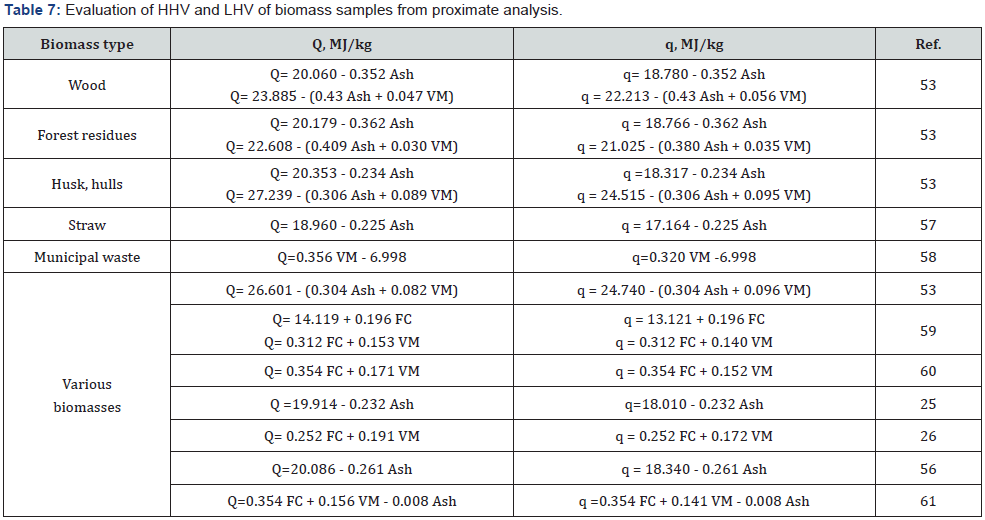

6 & 7).

The study of calculation methods based on proximate analysis

showed that the equations containing percentage of Ash, VM and

FC are insufficiently reliable, because the determination error

of these parameters is quite high. More reliable results can be

obtained using the equations based on the precise elemental

analysis of a specific type of biomass. For example, equation of

Tillman [54] is most suitable for calculating the heating value of

wood samples, whereas equation of Grabovsky & Bain [55,62] is

most suitable for estimating the heating value of straw biomass.

Calculations by means of “universal” equations averaging the

results of various biomasses show a higher discrepancy with

experiments than specific equations. Since an unlimited number

of different types of biomass exists, an unlimited number of

correlation equations is required to calculate the heating value. It

is clear that such task is not feasible.

For this reason, another approach is proposed [63]. It is

known that any plant biomass contains three natural biopolymers,

cellulose, hemicelluloses and lignin, as well as extractives and

some other substances. Thus, to evaluate the heating value of the

biomass sample it is sufficient to determine the heating value of

limited number of individual components and their content in the

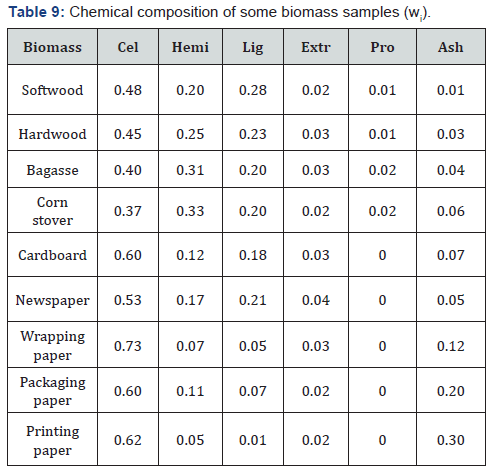

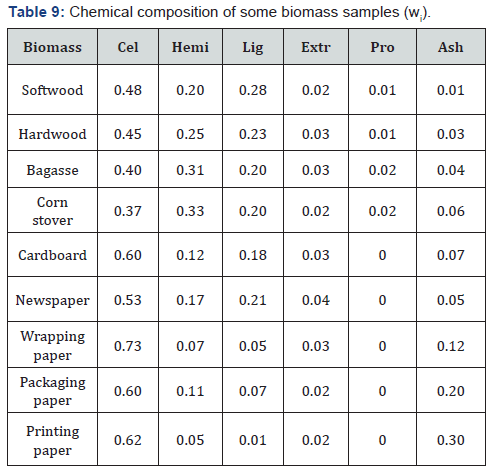

biomass, using the following equations:

where Qi and qi

are HHV and LHV (NCH)of individual

components in the biomass, which can be determined

experimentally or calculated using eq. (7), (10) or (14) (Table

8); wi is mass fraction of the corresponding components in dry

biomass sample (Table 9), which is determined by standard

methods of chemical analysis [51,52].

Note: Cel is Cellulose; Hemi is Hemicelluloses; Lig is Lignin;

Extr is Extractives; Pro is Proteins

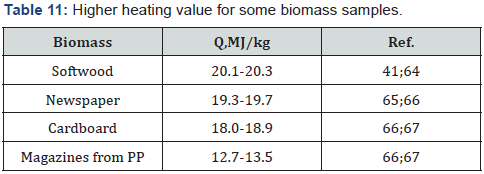

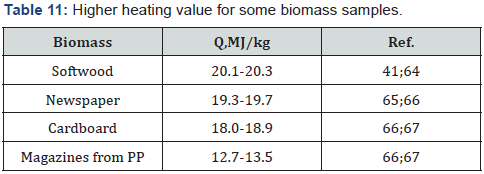

Using eq. (14) and (15), HHV and LHV of biomass samples

can be easily calculated (Table 10).The results showed that this

approach provides to calculate the heating values, which are close

to experimental values.

Note: MP is mixture of NP, WP, PA and PP

The obtained results are confirmed by literature data (Table

11).

Currently, around 400 million tons of paper and cardboard

(PB) are produced worldwide. However, after usage these

PB materials are thrown out and pollute the environment. In

economically developed countries such as the USA, Canada,

Western Europe, Japan and some others, about 50% of the waste

PB, mainly cardboard, is recycled. In Russia and China volume of

recycled PB is 20-30%. Unlike these countries, most Asian, African

and Latin America countries almost do not recycle the waste PB.

Thus, with an average of 75% of the waste BP or around 300

million tons in the world are land filled or burned.

As is known, the decomposition of PB and other organic waste

in dumps leads to emission of methane, which is recognized

20 times more dangerous greenhouse gas than carbon dioxide

[67,68]. Therefore, it is more preferable to burn the waste PB to

reduce the area of landfills, decrease CH4 emission and produce

heat or electricity [69]. For this purpose, it is necessary to know

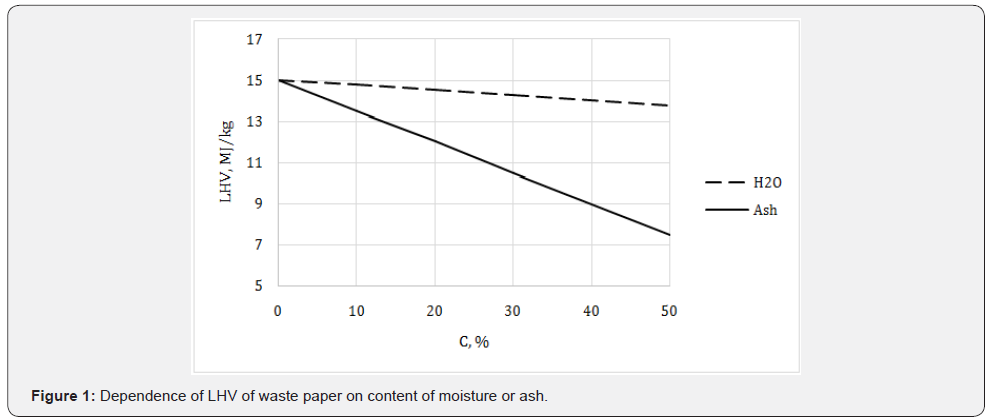

energetic characteristics of the waste. The statistical analysis

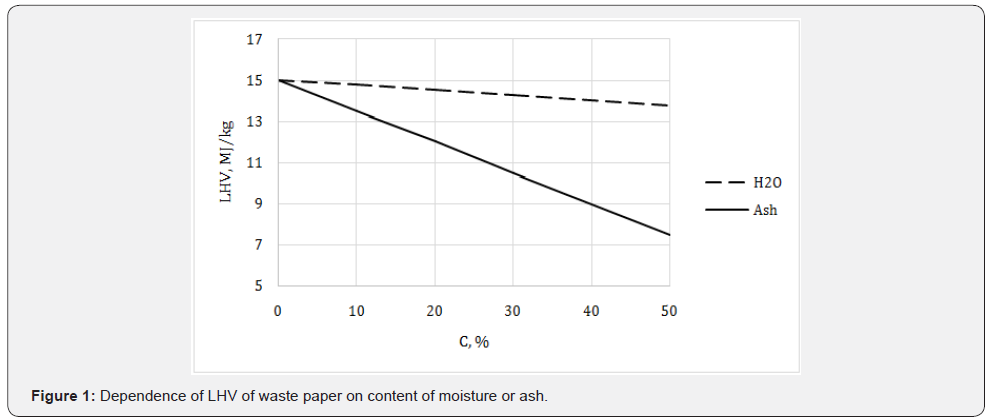

showed that the average net combustion heat of paper trash

is 15 MJ/kg in the dry state [67], which corresponds to LHV of

mixed waste paper (Table 10). In fact, a paper trash is always wet

and contains inorganic admixtures (ash); therefore its energy

potential is less than for dry and pure material (Figure 1).

An acute environmental problem is the accumulation of

synthetic polymers and their composites - plastics, which, unlike

biomass, are biostable and can persist in nature for hundreds of

years [70]. Every year in the world about 250-300 million tons

of synthetic polymers and plastics are manufactured [22]. Over

90% of all plastic products are made of rubber, polyethylene

(PE), polypropylene (PP), polystyrene (PS) and polyethylene

terephthalate (PET).Only part, 30-35%, of these waste, mainly

PET-bottles, rubber tires and some other polymeric articles, is

recycled in the world. But about 65-70% or 150-170 million tons

of biostable polymers and plastics are thrown away annually and

pollute the environment. The dumps occupy huge areas, which

are required for economy of countries. Moreover, in order to

equip the dump and keep it at the level of modern environmental

requirements, large funds are needed. Landfill sites are sources of

pollution of the environment with harmful substances contained

in plastics such as monomers, plasticizers, cross linkers, flame

retardants, etc. Particularly dangerous are small particles of

plastics. These pollutants poison the air, soil, water, and create a

danger to the vital activity of plants, animals and people.

A huge problem is the pollution of water bodies and oceans

with polymer debris [23]. Every year, up to 10 million tons of

plastics are thrown into the ocean. It was found that currently

more than 7 billion tons of biostable plastic waste have been

accumulated in the world. The cardinal way of destroying plastic

debris is burning. Despite CO2 emission, the modern technology of

burning (e.g. in plasmatrons) causes less harm to the environment

than the accumulation of huge volumes of biostable waste plastics.

Along with the eliminating plastic debris, this method allows to

receive an additional energy.

The specific thermal energy of synthetic polymers and plastics

can be determined experimentally using calorimetric bomb or

calculated by eq. (6), (9) or (13) (Table 2 & 4). Typical HHV and

LHV of the most spread synthetic polymers are shown in Table 12.

Thus, polyolefins (POL) and rubber (RUB) have higher

potential of heat energy than oxygen-, nitrogen- or halogencontaining

plastics (PMMA, PET, PA-6, PVC). The last four plastics

should be pulled out from plastic trash before combustion of POL,

RUB or mixture thereof.

As is known, waste of biomass and plastics have different

sizes, shapes and composition, as well as low bulk density. These

features of solid organic matters leads to unsatisfactory fuel

properties such as unstable calorific value, poor energetic density

and insufficient combustion efficiency [72,73]. For example, trash

of biomasscan have moisture from10 to 55%. Some biomass

residue or waste, e.g. rice straw or husk, packaging and printing

paper, contain from 15 to 30% of mineral components that

hinder combustion and reduce calorific value. The bulk density

of biomass varies from 40-80kg/m3 (grasses), to 150-200kg/m3

(wood chips), whereas the energy density is relative low, from 0.5

to 5GJ/m3. Plastics trash also contain pieces of various sizes and

shapes of different polymers with low bulk density, from 50 to

200kg/m3 that lead to low energy density, from 2 to 6GJ/m3. The

negative features of waste materials hinder their application as

solid fuels for the energy recovery. To overcome the low energetic

density and other negative fuel characteristics, the loose matters

should be converted into dense pellets or granules.

Pelletization of plant biomass is a well-known process, which

includes a number of steps: selection, removal of foreign pieces,

drying to a moisture content of 10% or less, shredding, grinding

to particle size of 1 to 3mm, hot pressing at 80-90oC into long rod,

cooling and cutting of the rod into pellets [73].The mineralized

and very wet materials must be previously removed at the

selection step. The pellets can be easily prepared from waste and

residues of various plant materials, but especially from feed stocks

having low moisture and ash content, as well as increased content

of lignin and lipids [1,74]. The raw material for the production of

granules is plastic waste. After disposal of PET bottles from trash,

the remained waste contains mainly polyolefins having average

HHV=42MJ/kg. Processing of plastic waste comprises steps of

removal of foreign materials, shredding, melting and granulating.

The prepared pellets and granules are strong and dense; they

have a typical bulk density of 600 -700kg/m3and energy density

of 10-12GJ/m3for biomass pellets and 20-30GJ/m3 for plastic

granules. Such densified solid fuels represent a promising source

of additional heat energy with improved burning productivity.

Besides, the compacted solid fuels are more economical to

transportation [75].

The granulation technology makes it possible to obtain fuel

granules with unique properties from mixed materials containing

both plastic and biomass waste [76]. The addition of plastic to

biomass reduces hydrophility and increases the strength, density

of energy and calorific value of the mixed solid fuel as compared

to biomass pellets only. Furthermore, since the plant biomass is

neutral for CO2- emission, burning of granules made from mixed

natural and synthetic materials results in a lower release of this

greenhouse gas in comparison with a separate burning of plastic

granules only.

Total amount of biomass aimed especially for energy

production is estimated at 7-8 billion tons with energetic potential

of 100-120EJ [77]. However, currently only half of this potential,

50-60EJ, is used to recovery energy from biomass, i.e. about

10%, of the global energy production [19]. Currently, biomass

is remained the main source of energy for population living in

rural areas of various countries, which uses firewood, chips,

sawdust, twigs, bushes, straw, and other plant residues as solid

biofuel to meet their energy needs. Share of biomass energy use

in developing counties is 75% and in developed counties is 25%

[77]. Besides, in economically developed countries the biomass

waste is burned as a part of MSW in order to eliminate solid

waste, reduce area of dumps, prevent environmental pollution

and generate additional energy [78]. Combined heat and power

systems that use the biomass-based fuel are widespread in

Europe and especially in the Scandinavian counties [79]. In North

America and European countries the thermal energy is generated

also by burning of waste from forest and paper industry, as well as

by burning of fuel pellets. Global production volume of the pellets

is about 30 million tons; moreover, the growth of the production

of such biofuel is expected to 50 million tons by 2020 [74].

As for plastics, it is known that over the last 70 years about

7 billion tons of wastes of various biostable plastics have been

accumulated in the world, not counting another 150-170 million

tons plastic waste that are thrown out every year. If gradually

incinerate this amount of waste for 10 years, about 24-25EJ of

thermal energy can be produced each year, whereas burning

of another 150-170 million tons of plastic waste gives 6-7EJ of

additional energy.

Thus, the total energetic potential of biomass and plastic

wastes is estimated at 140-150EJ per year, which can provide 22-

25% of the global energy production. Moreover, to produce the

thermal energy it is most promising to burn the granulated mixed

fuel containing biomass and additive of plastic waste.

Energy Potential of Liquid and Gaseous Fuels Extracted from Solid Polymer Materials

Solid polymer materials can be also converted into liquid and

gaseous fuels. For example, such known liquid fuel as ethanol

is produced from cellulose and various types of plant biomass.

Technology of cellulosic ethanol comprises three steps. The first

step is hydrolysis of cellulose with acids or cellulolytic enzymes

to obtain glucose:

(C6 H10 O5)n + nH2 O→nC6 H12 O6

The second step is fermentation of glucose into ethanol in the

presence of yeast:

C6 H12 O6→2C2 H5 OH + 2CO2

And the final stage is distillation and dehydration of ethanol.

The theoretical yield of ethanol is 51% from mass of glucose

and about 57% from mass of cellulose, but the actual yield is lower.

A more difficult task is to obtain ethanol from biomass.

This is due to the dense structure of plant materials and barrier

properties of lignin, which hinder the diffusion of hydrolyzing

reagents - acid or enzyme [80,81]. Therefore, a pretreatment

step is applied to make the biomass more accessible to reagents.

The main objectives of pretreatment are to loosen the physical

structure of biomass and to eliminate the lignin in order to

increase accessibility of biomass and the percentage of cellulose

fraction. Various pretreatment methods of lingo cellulosic

biomass can be used such as steam explosion, acidic treatment,

alkaline extraction, oxidation, organosolv and some others [81-

84]. Among various methods, alkaline pretreatment of plant

biomasses under mild conditions is intensively studied due to

their industrial feasibility, relatively low capital investment, as

well as low consumption of chemicals and energy [83-85]. Twostep

pretreatment using combinations of acid and alkali are

considered as very effective [86,87].

Hydrolysis step of cellulose in pretreated biomass is

usually

carried out by cocktail of cellulolytic enzymes, which provide a

higher yield of glucose than acid hydrolysis. This cocktail consists of

three main enzyme types, endoglucanase, exo-glucanase and

beta-glycosidase, acting synergistically [80].

Known types of enzymatic cocktails are CellicCTec 2 and

CellicCTec 3 of Novozymes, as well as Accellerase-1500 and GC-

220 of DuPont/Genencor. Optimal conditions of the enzymatic

hydrolysis are the following: temperature is 45 to 50 °C, pH = 4.5

to 5.0, dose of enzymes is 10 to 20mg per 1g of solid biomass and

loading of biomass substrate is 140-160g/L.

The fermentation of glucose solution obtained after enzymatic

hydrolysis of the pretreated biomass is carried out usually by the

yeast of Saccharomyces cerevisiae in the presence of nutrients at

30 °C and pH=5 [88].Various fermentation methods can be used:

simultaneous saccharification and fermentation, simultaneous

saccharification and co-fermentation, sequential fermentation,

continuous fermentation, etc. The final concentration of ethanol

after fermentation step is usually 50-60g/L. Therefore the dilute

“beer” is distilled to obtain 95-96% of ethanol. Since the fuel

ethanol should not contain more than 1% water, the distilled

ethanol is dehydrated to 99% using dewatering agents, e.g. zeolites.

The yield of ethanol at the same saccharification and fermentation

conditions depends on type of biomass and pretreatment method.

For example, yield of ethanol from alkali pretreated corn stover is

30-35% that is 18-21% from initial biomass.

Hydrolyzate of cellulose or pretreated biomass containing

glucose can be fermented also by oleaginous microorganisms for

lipid production. They are yeasts of Rhorosporidiumtoruloides,

Lipomycesstarkeyi, Mortierellaisabellina, Trichosporonfermentans,

Cryptococcus curvatus etc. [89,90]. The fermentation of glucose

solution with oleaginous yeasts was carried out at 30oC while

stirring for 4-7 days. As results, from 20 to 50% of glucose are

converted to lipids, which further can be uses for production of

biodiesel fuel [91,92].

The technology of biodiesel fuel is based on transesterification

reaction between lipid and alcohol, e.g. methanol, in the presence

of alkaline or acid catalysts [93, 94]:

C3 H5 (O2 CR)3 + 3CH3 OH →3RCO2 CH3 +C3 H5 (OH)3

The obtained ester is used as a biodiesel fuel, and the

byproduct, glycerol, can be utilized for some other applications.

Anaerobic digestion of biomass allows to obtain biogas

such as methane. The most appropriate feed stocks for biogas

production are waste paper or residue of pulp and paper industry.

Lignocellulosic biomass can be pretreated to loosen the physical

structure of substrate and reduce content of lignin hindering the

bioconversion process [95]. The dilute aqueous dispersion of

substrate (5-10%) is digested in a bioreactor under anaerobic

conditions at optimal pH of 6.8-7.4 under the action of mesophilic

bacteria at temperature of 30-40 °C or thermophilic bacteria at

temperature of 50-60 °C. The source of these bacteria can be

sludge of sewage or cattle manure. The process of anaerobic

biodegradation usually takes 2.5 to 3 weeks.

The process of anaerobic biodegradation of organic substances

occurs in several stages [96]. In the first stage, hydrolysis, the

complex molecules (СM) of organic substances break down into

simple molecules (SM). In the second stage, acetogenesis, simple

molecules produced in the first stage are converted to acetic acid

(AA). In the last stage, methanogenesis, acetic acid is converted to

biogas (BG) containing methane, carbon dioxide and some other

gases.

CM →SM → AA→ BG

For example, cellulose and other C6-polysacharides (C6 PS)

are hydrolyzed into monomeric glucose (GL). Further, glucose

forms acetic acid, which is transformed into biogas.

C6 PS →GL → AA → BG

(1). C6 H10 O5 + H2 O→C6 H12 O6

(2). C6 H12 O6 →3CH3 COOH

(3). 3CH3 COOH →3CH4 + 3CO2

Total process: C6 H10 O5 + H2 O→3CH4 + 3CO2

The anaerobic digestion of xylan and others C5-polysacharides

(pentosans) can be described as follows:

(1). C5 H8 O4 + H2 O→C5 H10 O5

(2). C5 H10 O5 →2.5CH3 COOH

(3). 2.5CH3 COOH →2.5CH4 + 2.5CO

Total process: C5 H8 O4 + H2 O→2.5CH + 2.5CO2

The theoretical yield of biogas ( YYg ), containing mixture of CH4

and CO2, and methane only (

Ym ) from 1 t of dry organic substance

(DOS) with molecular weight, M (g/mole), can be calculated by

the equations [97]:

Where m and k is number of moles of CH4 and CO2, respectively,

formed from 1 mole of DOS.

Using Eq (16) and (17) it can be calculated that the theoretical

yield of biogas from 1 t of cellulose and other C6 PS is 830 m3

and of methane is 415m3. In the case of pentosans the theoretical

yield of biogas is 848m3, whereas of methane is 424m3 from 1 t

of DOS. Maximum yield of biogas from 1 t of biomass, containing

65% of polysaccharides (PS), is about 546m3 and of methane

273m3.However, the actual yield of biogas and methane from

plant polymers and biomass for real time of bioconversion is

significantly lower. For example, bacterial digestion of 1 t wheat

straw with 65% content for 3 weeks of polysaccharides results in

the production of about 150m3 methane, i.e. 55% from theoretical

yield.

Biomass of microalgae is promising raw-material for

bioenergy recovery. Microalgae (MA) include variety of species such as Ankistrodesmus, Botryococcus. Chlorella, Nannochloropsis,

Neochloris, Nitzschia, Scenedesmus, Schizochytrium etc. The

peculiarity of MA is that they contain lipids. Among them

Schizochytrium, Nannochloropsis and Botryococcus contain

particularly high amount of lipids up to 70-75% [98]. Extracted

lipids are used for production of biodiesel fuel through

transesterification reaction [99,100]. The residual biomass of MA

remaining after extraction of lipids can be burned or subjected to

anaerobic digestion to produce biogas [101].

Liquid and gaseous fuels are obtained also by pyrolysis of

biomass or plastics. Biomass wastes and residues are subjected

usually for this purpose. The main products of the pyrolysis

are bio-oil, gases and charcoal [102,103]. The yield of various

products is dependent on conditions of the pyrolysis process and

biomass composition. Slow pyrolysis of the biomass is carried

out at heating rate ≤1degree per sec up to 400-500 °C and typical

residence time of 10 to 20min with formation of 20 to 40% biooil,

30 to 50% gases and 25 to 35% charcoal. If the pyrolysis

temperature is above 500 °C, a decrease in the yield of charcoal

is observed. Slow pyrolysis of biomass at high temperatures, 800

to 1000 °C in the inert or steam atmosphere causes the formation

mainly gaseous product containing CO2, CO, H2, CH4 and some

other gases with calorific value 10- 12MJ/Nm3or 14-16MJ/kg

[104].

Fast pyrolysis is performed at heating rate 100-200degrees

per sec, temperature above 800 °C and short residence time

especially to increase the yield of bio-oil. Flash pyrolysis at heating

rate above 1000 degrees per sec and temperature above 1000 °C

allows obtain the bio-oil with a high yield of 70-75%. The calorific

value of the bio-oil is 15-17MJ/kg, which is significantly lower

than of ethanol, biodiesel and hydrocarbon fuels [1]. Pyrolysis

method is used also for decomposition of waste plastics to obtain

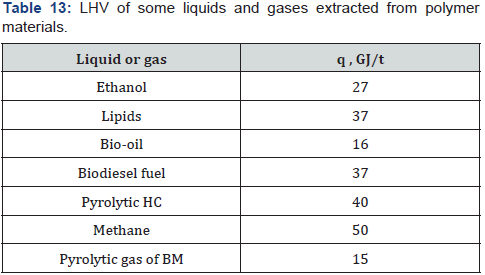

combustible liquids–pyrolytic hydrocarbons (HC) [105,106].

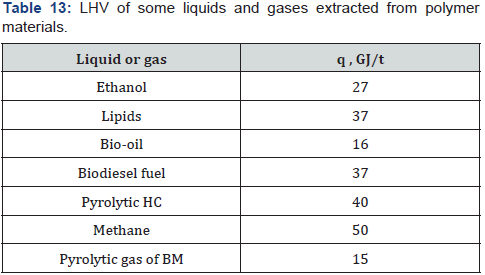

Calorific values of various liquid and gases extracted from biomass

or plastics are shown in Table 13.

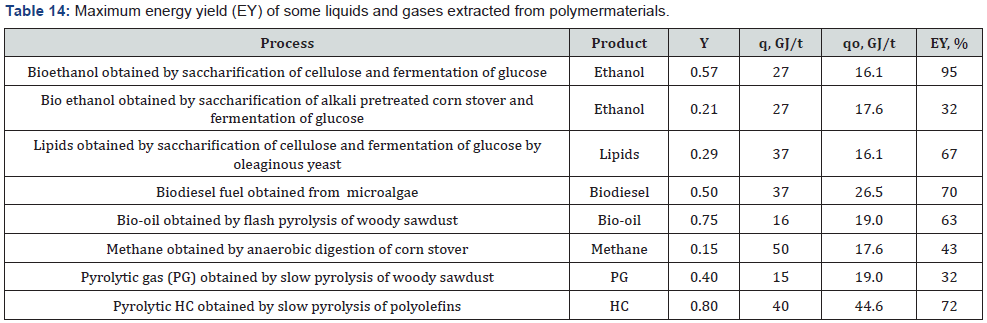

These values were used to calculate the energy yield (EY):

Where Y is yield of liquid or gas (t) obtained from 1 t of initial

polymer material; q is LHV of liquid or gas (GJ/t), and qo is LHV of

initial polymer material (GJ/t)

Knowledge of the energy yield allows to understand that it

is more advantageous, the direct burning of the starting polymer

material (biomass or plastic), or the burning of various liquid or

gaseous fuels extracted from this material? The typical examples

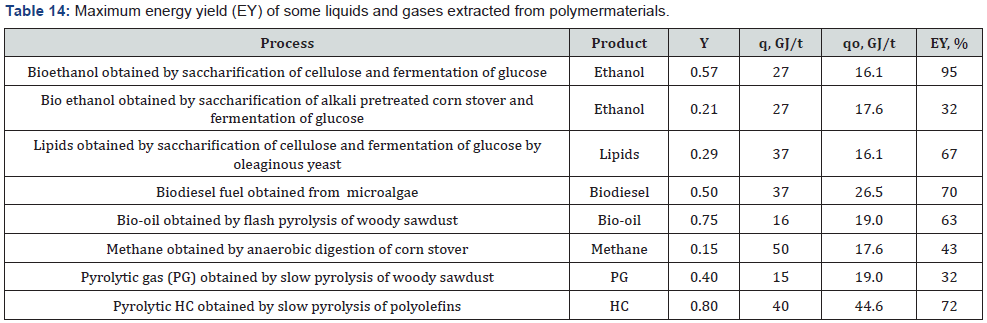

of energy recovery are presented in Table 14.

Analysis of these typical examples reveals that in all cases

the energy yield of liquid or gaseous products extracted from 1

t of starting materials (biomass or plastic) is significantly lower

than the thermal energy of 1 t of the starting materials (Table 14),

(Figure 2).

Thus, to generate the thermal energy, it is more profitable to

burn the starting material as solid fuel, than extracted liquid or

gaseous fuels.

Conclusion

The energy potential of natural and synthetic polymers, plant

biomass, plastics and their solid waste, as well as combustible

liquids and gases derived from them has been studied. To

determine calorific values of solid, liquid and gaseous substances

various experimental and calculation methods were used. For this

purpose, improved equations based on chemical structure and

elemental analysis was proposed. It was shown that conversion of

solid materials into liquids or gases decreases the yield of thermal

energy. Therefore for the production of thermal energy, it is more

profitable to burn the solid biomass or plastic than combustible

liquids and gases, derived from them. Studies have shown that

lipids and lignin increase, whereas moisture and ash reduce the

calorific value of biomass. The calorific value of most synthetic

polymers and plastics is higher than that of biomass samples, but

resources of waste plastics are about 10 times lower than these of

biomass. It is most promising to burn the granulated mixed fuel

containing biomass and about 10% additive of plastic waste, since

it enables to increase calorific value and energy density of biomass,

as well as to reduce emission of carbon dioxide in comparison

with separate incineration of plastic only. Considering the total

amount of biomass and plastics waste destined for combustion,

it was calculated that current annual energy potential of biomass

is about 115EJ, and of plastic waste about 30EJ, which can cover

together about 24% of the world’s annual energy production. The

problem is that plastics are produced from fossil raw materials,

whose reserves are not sustainable and permanently depleted. In

this regard, the wider use of biomass has a significant advantage

because their reserves in nature are huge and continuously

renewed. In the near future, it is planned to increase the share

of biomass in the production of alternative energy twice at

least, which can simultaneously contribute to reducing in green

house gas emission and improving the ecological state of the

environment.

For more

details Academic

Journal of Polymer Science please click on: https://juniperpublishers.com/ajop/index.php

To read more…Full Text in in Juniper

Publishers click on https://juniperpublishers.com/ajop/AJOP.MS.ID.555553.php

Comments

Post a Comment