A Novel Empirical Approach to Estimate the Acoustic Properties of Smart Materials: Part I-Juniper Publishers

Authored

by Francesca Nanni

With:

and the variation in frequency

of the Δf -nth eigen mode from the average value, this last constraint imposes the minimization of the index

, indicating the homogeneity in the distance between different mode shapes.

is represented as a bold black line in the graph.

Abstract

In this work, a novel empirical approach to the

estimation of the rheological behaviour of smart materials from the

sound insulation capabilities is proposed. The testing protocol relies

on a small sound research facility that was designed with the goal of

achieving a movable yet flexible measurement system, suitable for both

laboratory environments and quality assurance departments.

Unlike other test protocols relying on lightweight

acoustic research solutions, the proposed methodology was developed to

perform acoustic tests in a diffused field environment, a test condition

much closer to real life applications, and in a sufficiently wide

frequency range (eg. 2 -10kHz).

The proposed test methodology was validated by means

of modal analysis of the chamber and by comparison between empirical

acoustical test results (insertion loss) and the expected theoretical

results.

At last, as a proof of concept, it is showed how to

apply the proposed protocol to the measurement of the sound insulation

of a novel laminate containing a nano composite core and how to evaluate

indirectly the rheological behaviour merely from acoustical data.

Keywords: Acoustics; QA; Smart materials; Sound-insulation

Introduction

The development of Smart materials, composite systems

capable of altering their properties when subjected to external

stimuli, has brought about a revolution in materials science and in

modern society as a whole. In fact, smart materials can be designed

basing on the requirements of a particular application and the response

can be tailored up to the customer’s needs, thus allowing engineers to

develop materials with many different functions embedded.

The alteration can be triggered either by means of

autonomous modifications in the microstructure of the material (passive

smart materials) or by means of external control systems (active or

semi-active smart materials). The first class is based on non-Newtonian

fluids such as Shear-thickening fluids, while the latter on magneto

rheological and electro rheological fluids.

In particular, as smart materials can alter their

vibration damping properties, they prove to be particularly interesting

for acoustic applications in the aeronautical and automotive field, in

which the acoustic comfort of the cabin interior is a major concern.

These advanced composites usually comprise

non-Newtonian fluids encapsulated in a stiffer medium. In particular, as

most smart materials are used in lightweight structures such as

sandwich panels, smart materials are usually interposed as the core of

laminates in constrained layer damping (CLD) configuration.

Furthermore, active or semi-active smart materials

allow for the optimization of the performance of the material for a wide

range of working conditions, as the associated control system modifies

the acoustical response. The acoustical response of Smart materials is

heavily influenced by the rheological response of non-Newtonian fluids

at acoustically significant frequencies,

typically in the kHz range. In practice, in order to evaluate the

acoustical performance of a newly developed Smart material,

as the maximum oscillation frequency of the most commonly

available rheometers is less than 16Hz, regression methods to

derive the high-frequency data from low-frequency rheological

data must be employed.

These methods solve an ill-posed mathematical problem

(Tikhonoff inverse problem), where acoustical data must be

extrapolated from experimental rheological measurements with

an unknown error [1,2]. These numerical methods to evaluate the

acoustical response of smart materials, although tempting, are

still undergoing intensive studies in various fields of research and

typically require massive rheological experimental campaigns

and the solvers are CPU intensive. In the second instance, these

numerical methods only provide a first good estimate of the

acoustical properties of the core, as the acoustical properties of

the smart material are dependent on the boundaries and loads

applied on the full structure.

As a consequence, as R&D laboratories often present the

necessity of testing the outputs of the research right after the

chemical synthesis of the material, it is desirable to find an

empirical approach to provide a preliminary good estimation of

the acoustical properties of the final sandwich structure.

Furthermore, as shown in previous works [3], sound

transmission loss or insertion loss tests can be used as an

alternative to other non-destructive tests (NDT) and can provide

valuable information concerning the mechanical properties of

CLD structures and structures that present adhesive joints or

other permanent bonds as well.

In the following, a novel empirical approach to the evaluation

of the sound insulation properties of smart materials will be

proposed. This method will rely on the design of an Acoustic

Properties Evaluation-Small Room Facility (APESR facility).

The whole leitmotiv of the proposed design procedure relies

on the extension of the measurable frequency range, the weight

reduction of the structure and the maximisation of the versatility

of the facility itself. Secondarily, the APE SR facility was designed

in a modular way, with the possibility of joining it with another

reverberation chamber or anechoic chamber.

This design choice in the future, can allow for changes in the

sound test layout. Finally, it was taken into account the possibility

of attaching a shaker [4,5], for forced-response vibroacoustic

tests. In fact, during the design process, it was considered the

necessity of achieving a sound research facility suitable for

addressing both sound transmission loss and sound absorption

loss, respectively by means of insertion loss (and/or transmission

loss) test evaluations and sound absorption test evaluations.

While traditional sound transmission loss tests performed

in standardized facilities require non-negligible amounts of

materials for the test samples (up to 6square meters), the APE SR

facility was designed trying to minimize the amount of material

necessary for each test. ISO A3 samples were considered as a

reasonable compromise between good measurements (the larger

the sample, the better) and typical laboratory material production

rates.

On the other hand, even though standard laboratory tests like

the ones performed by using impedance tubes [6], require small

samples, they only allow normal incidence sound fields and very

narrow frequency bandwidths. Therefore, the design of the main

body of the reverberation chamber is characterised by some main

critical factors: volume of the acoustical cavity, shape of the cavity,

surface finish of the internal surface and effect of the closing wall.

The interior volume of the small reverberation chamber

introduces limitations as far as the analysis at lower frequencies

is regarded. This can be traced back to the modal response of the

air volume, characterized by highly superposed and singularly

undistinguishable modes. The lower limit to the beginning of this

chaotic dynamic response is given by the Schroeder frequency,

which is inversely proportional to the air volume contained inside

the reverberation chamber.

Below this lower limit, the absolute results of the sound

insertion loss and sound transmission loss tests are not reliable,

but the experimental data can however be useful for comparative

tests. The shape of the cavity affects the modal distribution: the

more irregular, the more homogeneous the distribution. However,

more complex shapes tend to reduce the stiffness to weight ratio

of the structure, thus limiting its mobility and requiring higher

production costs.

On the other hand, the surface finishing influences the cut-off

frequency of the measurable frequencies. Finally, the dimension

of the opening window, which doubles as a sample holder for

insertion loss tests, influences the measurements because smaller

samples tend to resent more of the boundary effects. In other term,

it must be found a good compromise for the sample dimension:

the larger the sample, the more negligible are the boundary effects

and the more material is required in order to perform each test.

All of these factors will be analysed at great lengths in the

following.

Theory/Calculation

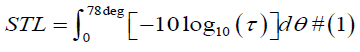

Insertion loss measurements

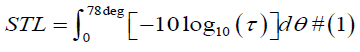

The sound insulation properties of a material can be indicated

by means of the sound transmission loss (STL) parameter. This

parameter, expressed in the dB scale, can be derived from the

acoustic transmissibility as follows.

As an example, for a CLD sandwich with skins named 1 and 2,

can be estimated as follow

Where:

i. k is the wave number.

ii. θ is the integration angle that varies from 0deg to 78deg.

This particular value derives form numerical considerations,

as the contribution of angles higher than this are negligible to

the sound insulation properties of the panel [7].

iii. Z is the acoustical impedance.

iv. m is the surface density of the panel.

v. air ρ is the density of air.

vi. G∗ (ω ) is the frequency dependent complex shear

modulus of the core.

vii. h is the thickness.

viii. v is the Poisson modulus.

Theoretically, if all parameters are known, the STL can be

estimated from low-frequency rheological data by substituting

the frequency dependent shear modulus in the equation.

However, as this parameter requires a rather complex

numerical regression, it is possible to provide a first estimate of

the sound insulation properties of a polymer by extrapolating the

shear modulus form the measured STL spectrum. This spectrum

can be measured by means of a sound insertion loss (IL) test.

In this case, the test will be performed by employing

opportunely baffled samples inserted in a modified reverberation

chamber.

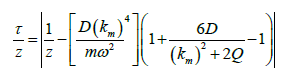

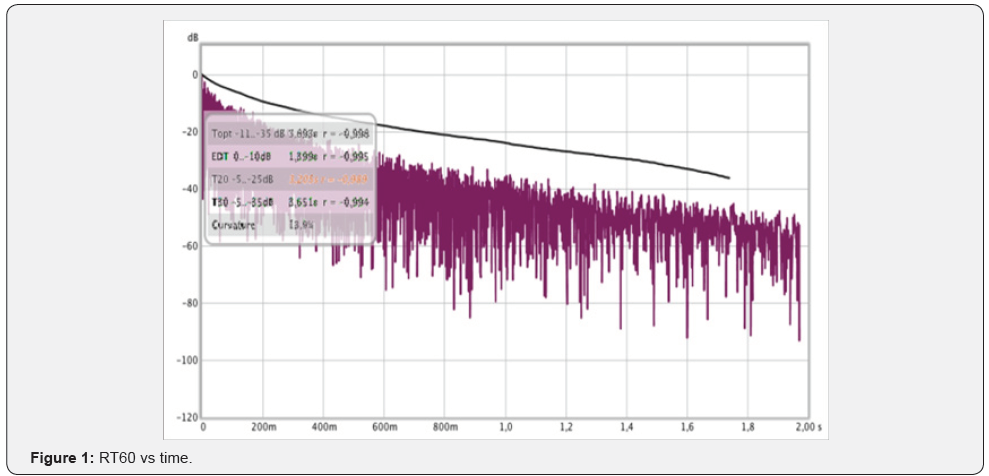

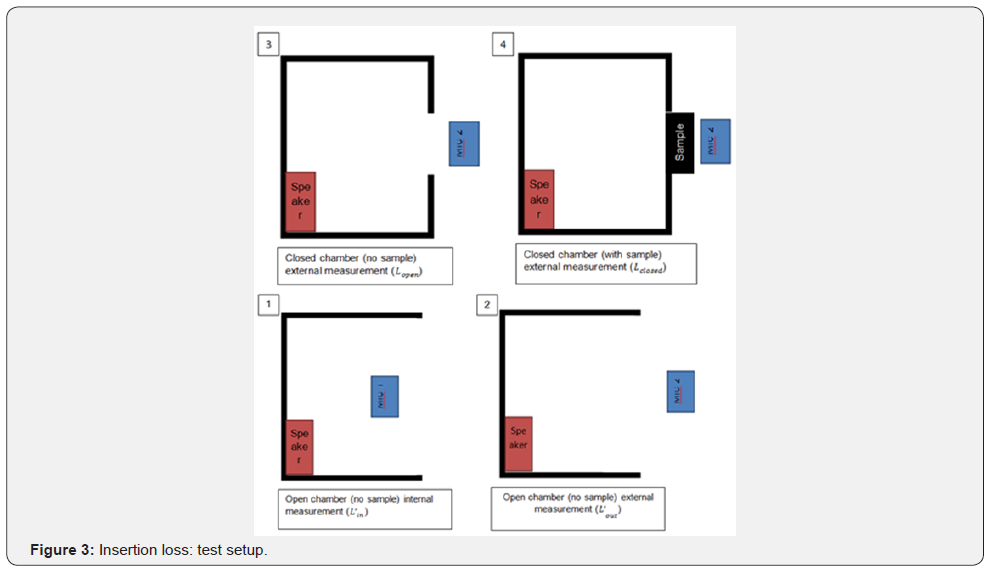

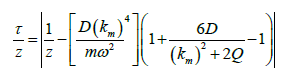

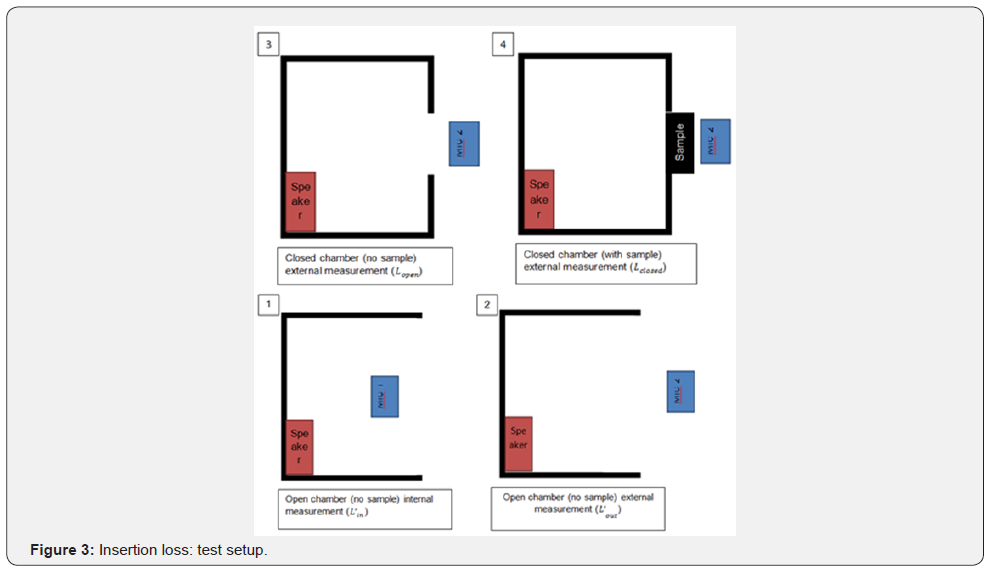

In general, the IL evaluation is based on the measurement of

the sound pressure field in four different configurations:

i. Front wall open + internal microphone in Lin'

ii. Front wall open + external microphone Lout'

iii. Front wall closed (no sample) + external microphone

Lopen'

iv. Front wall closed (with sample) + external microphone

Lclosed'

v. The sound transmission loss of the sample is equal to

(Figure 1 & Figure 2):

Preliminary considerations

The main global design prerequisites for the reverberation

chamber can be resumed as follow:

i. Minimal amount of space required for the whole

structure (accessories and base frame included).

ii. Minimal wall thickness imposed by the necessity of

sound insulation inside the chamber and stiffness of the

structure during the construction and transport phases

iii. Shape of the cavity motivated by the desire to homogenize

the natural mode distribution on the whole spectrum

iv. Maximisation of the internal volume in the chamber, in

order to minimize the lower measurement limit imposed by

the Schroeder frequency [7-10];

v. Minimum porosity of the internal surface, in order to

increase the cut-off frequency of the structure [11].

Before proceeding, it was considered as a minimum

acceptable frequency range for sound insulation measurements

2000-10000Hz, compatible with many engineering applications

of industrial interest, from an acoustical perspective.

Taking into account the previously listed requisites, it was

chosen for the main body of the reverberation chamber a concrete

cube with a cavity on the front side (Figure 3). The front side

presents threaded wire for a secure attachment of the closing wall

or the second reverberation/anechoic chamber.

On a side note, even if opportunely shaped hexahedral

cavities were proven to provide a more uniform distribution of

the natural frequencies [12], the internal cavity of the APE SR

was shaped as a rectangular parallelepiped, because of the better

stiffness to weight ratio of the structure of the latter solution

and, as a consequence, higher manoeuvrability. For the base of

the reverberation chamber, it was chosen a frame connected to

pneumatic vibration isolators (4Hz cut-off frequency).

These last structural elements, interposed between the

frame and the main body of the reverberation chamber, serve

the purpose of decoupling the structure from the external

environment, in order to minimize the external influences (i.e.

floor vibrations, shaker induced structure borne vibrations)

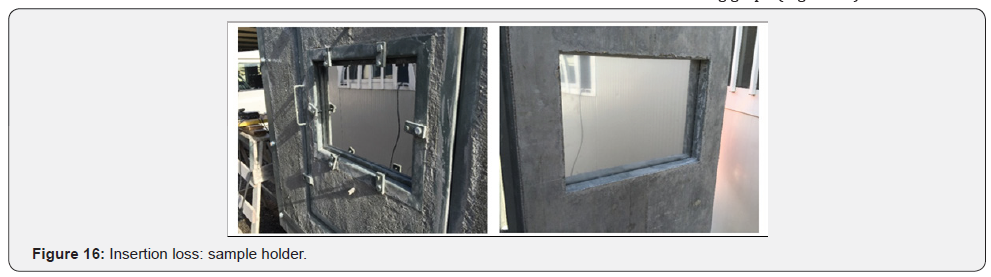

during the measurement phase. The closing wall is fashioned

with the same goal of achieving a multi-purpose structure and

presents a movable inspection panel, with a detachable sample

holder, allowing a “clamped” boundary condition. We installed

ulterior threaded wires for attaching the measure apparatus

(i.e. omnidirectional microphone) and a secondary anechoic

chamber; both used in transmission loss (TL) and insertion loss

(IL) evaluations.

Design and optimization of the APESR facility

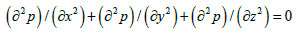

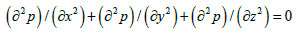

Staring from the solution of Helmholtz’s equation, it is possible

to evaluate the distribution of the modes of the system [13-16].

Taking into account the infinitely rigid boundaries, we can

assume that the wall specific impedance is infinite and the velocity

field at the boundaries is null.

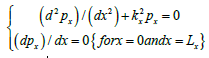

In a Cartesian reference system with axis parallel to the sides

of the enclosed cavity:

By substituting the trial solution p( x ,y, z) = px( x) py( y) pz( z)

into the wave equation(1), this is decomposed into three analogous

ordinary differential equations (ODE), where the only difference

is in the coordinates (x in the first, y in the second and z in the

third one). The same consideration is verified for the rigid wall

boundary conditions (BC). From now on, the discussion will be

focused on the first ODE and its BC (the one in the x coordinate),

but the obtained results can be easily inferred for the other two

equations.

The function Px , in order to be physically acceptable, must

verify the following conditions (2):

Where Lx denotes the base width, considering the origin of

the reference systemlocated in a vertex of the base rectangle.

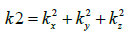

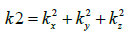

The three orthogonal components of wave numbers k must

satisfy the following condition:

The solution of the first ODE can be written as: px( x)=A1cos(kxx=B1kxx)

In order to satisfy the imposed BCs, 1 B = 0

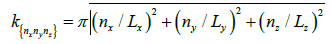

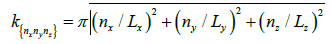

and Kx = (nx π)/ Lx

where nx is a generic natural number.

By substituting these last equations (and the analogous ones

for Ky and Kz into equation (3), we obtain:

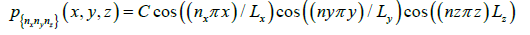

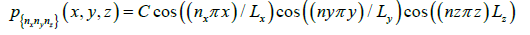

Associated to the eigenvectors, we can evaluate the functions:

Where C is an arbitrary constant which satisfies the boundary

conditions.

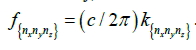

Finally, the associated eigen frequencies of the air cavity are:

At this point, it is possible optimizing, from an acoustical

perspective, the shape of the cavity considering the following

constraints:

i. Maximum stiffness-to-weight ratio of the structure

ii. Maximum Schroeder’s frequency

iii. Uniform distribution of the eigenfrequencies

iv. Construction simplicity.

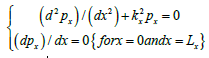

Taking into account the average distance between two successive eigenmodes

and the variation in frequency

of the Δf -nth eigen mode from the average value, this last constraint imposes the minimization of the index

, indicating the homogeneity in the distance between different mode shapes.

This constrained optimization was further refined by Blaszak’s

method [9,17], consisting in the minimisation of a secondary

index

This simultaneous constrained optimization, carried out

while taking into account the ease of construction of the structure

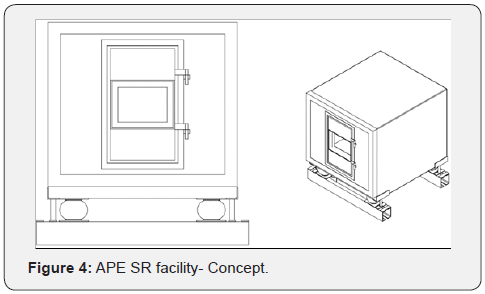

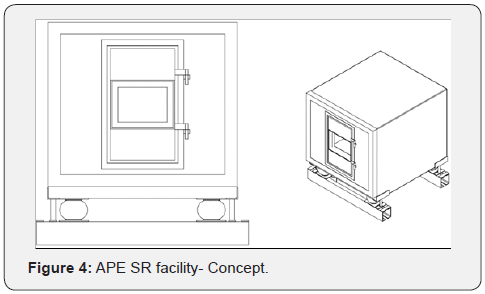

and other technological constraints, led to the design shown in the

following schematics (Figure 4):

This results rounds down Blaszak’s proportion fora

reverberation chamber with walls characterised by an average

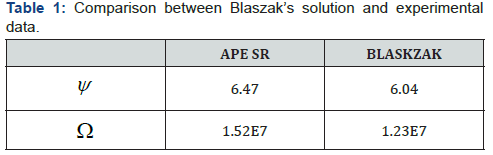

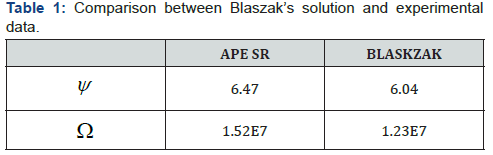

acoustic absorption of α ≈ 0.01(1:1.2 :1.4). The differences between Ωψ for the two solutions are shown in the following table

(Table 1):

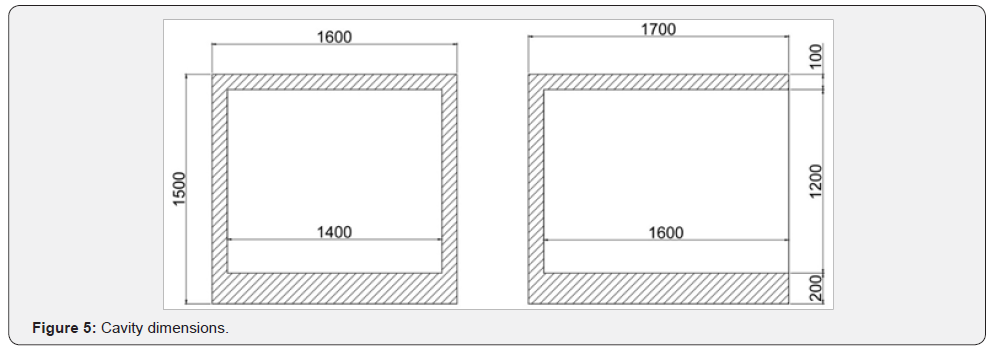

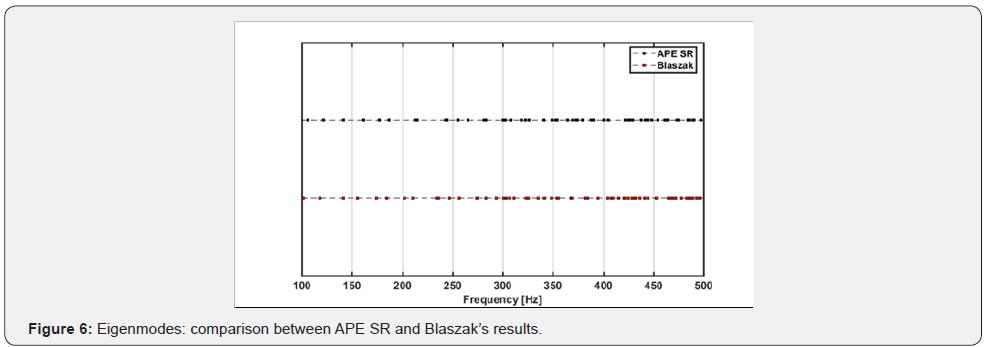

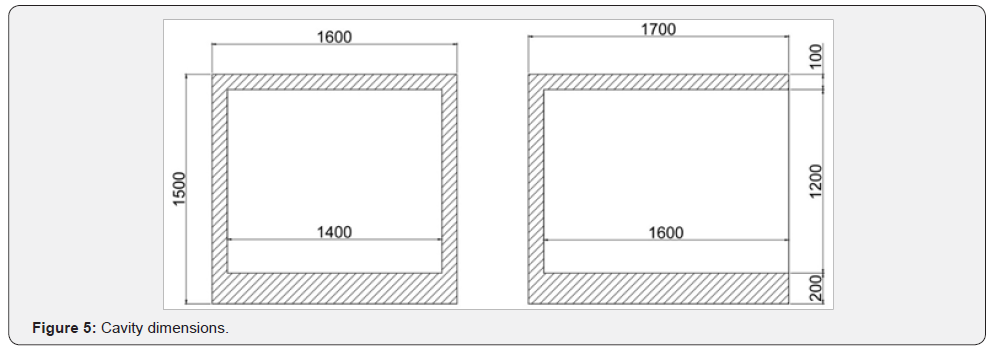

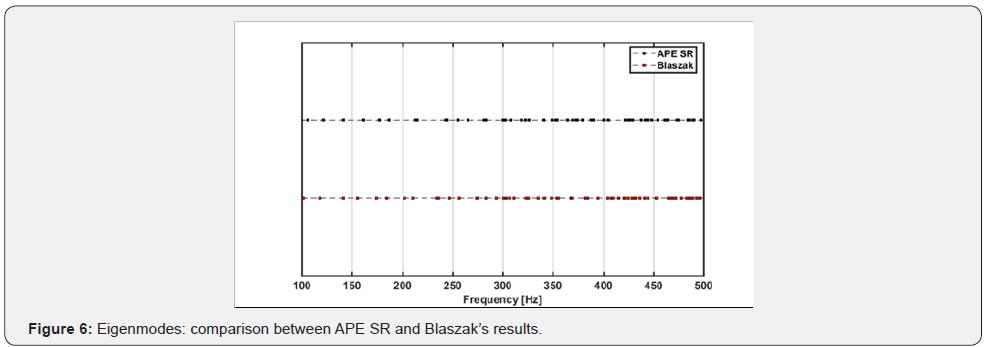

The differences between the proposed design and Blaszak’s

optimised design in terms of eigenmodes distribution can be

shown in the following graph (Figure 5). The graph considersa

hypothetic reverberation chamber with internal dimensions of

1.20mx1.44mx1.68m (which accords to Blaszak’s proportion).

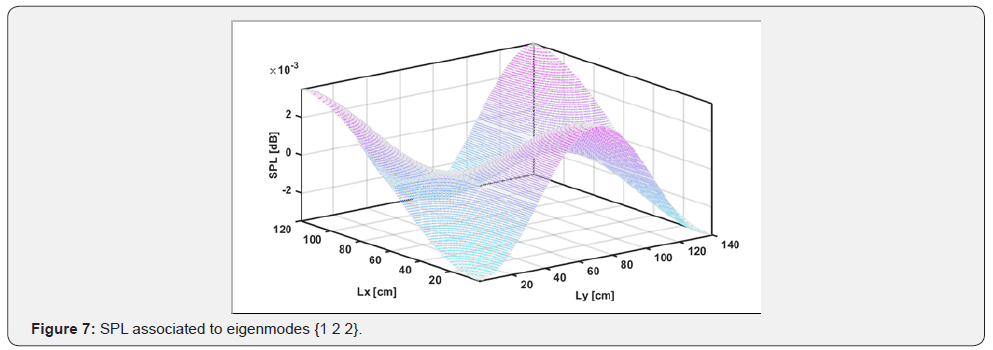

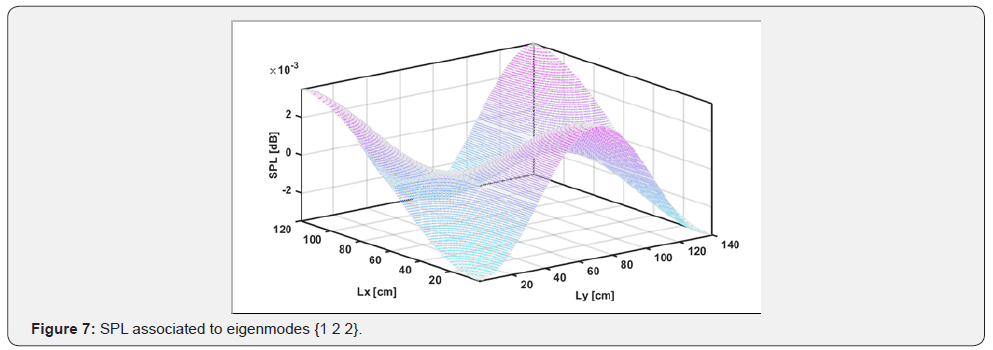

By substitutingthe eigenmodes inside the Helmholtz’s equation,

it is possible to evaluate the acoustic pressure field for the various

eigenmodes. For example, in the following Figure 6, it is shown the

sound pressure level (SPL) in the x-y plane at z=50 [cm] associated

toeigen modes {1 2 2}.

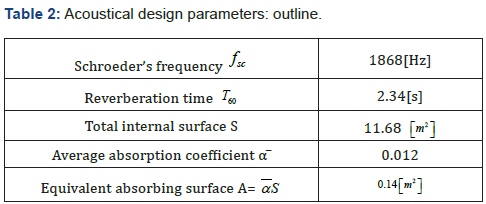

From a merely qualitative perspective, it can be noticed that

the regions where the sound pressure level is null coincide with

the projections of the nodal planes on the x,y plane. In conclusion,

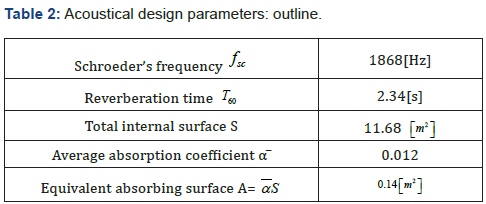

the acoustical design parameters can be summarized in the

following (Table 2).

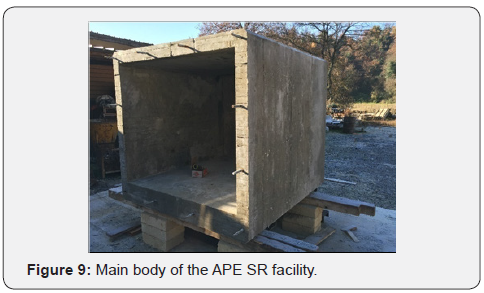

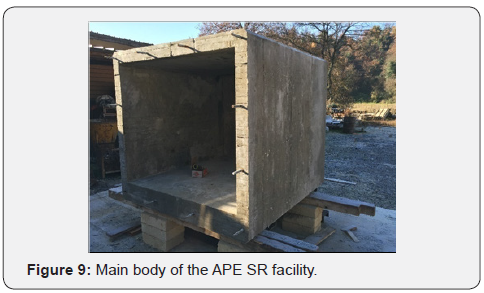

Construction of the sound research facility

The material chosen for the construction of the reverberation

chamber was reinforced concrete, because of the low cost,

low acoustic absorption and high density. This last parameter

influences the acoustic insulation properties and the seismic

mass of the system: the higher the density, the better the sound

insulation. The reverberation chamber was manufactured by

using a mix design of Portland cement (type II/A-LL 45,2R) and

finely grinded sand which was compacted both by ultrasonic

means (needle compaction) and external means (vibrating plate

compaction). This process was carried out in order to maximize

the sound reflection and minimize the absorption caused by local

Helmholtz resonator effects.

This acoustical mechanism can be traced back to the microporosities

naturally present in concrete-based structures. In

order to reduce the sound absorption of the concrete, the interior

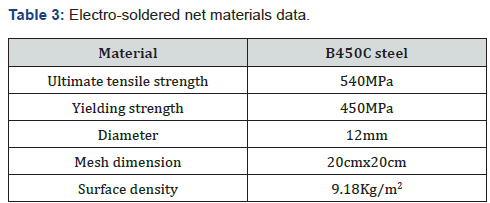

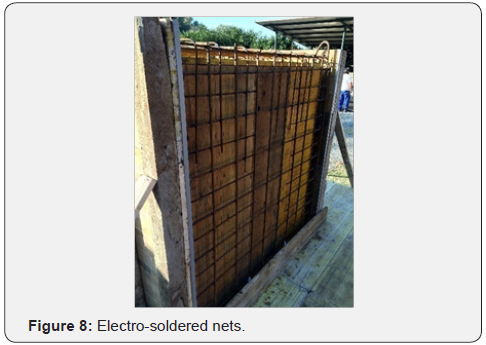

of the cavity was furtherly coated with a thin layer of stucco. The

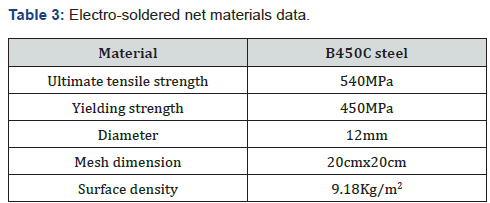

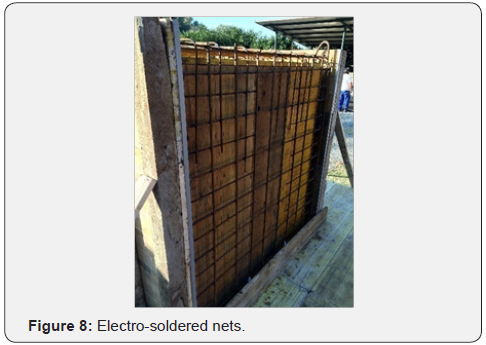

concrete was reinforced with an electro-soldered steel net with

the following characteristics (Table 3).

Because of the necessity of rotating the structure once the

concrete dried, the reverberation chamber was designed with a

reinforced bottom, with two electro-soldered nets Figure 7 and

an increased wall thickness of 200mm [18]. The structure was

removed from the mould after 2days and the concrete was left

to maturate for 30 days before the rotation (see rotated APE SR

in Figure 8), in order to increase its compression strength up to

42.5MPa and to minimize the risk of failure.

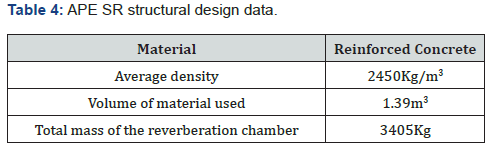

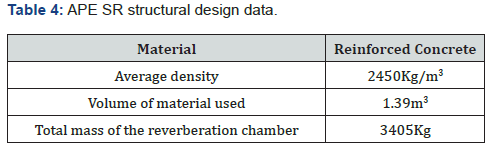

The design data can be resumed in the following table (Table

4):

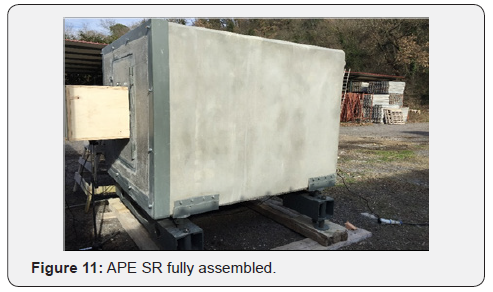

In order to decouple the dynamic response of the reverberation

chamber from the floor vibrations [19-21], for the suspension

system were used 4 pneumatic suspensions (Figure 9), each one

with a load bearing capability up to 1600kg at 7 bar [22]. The

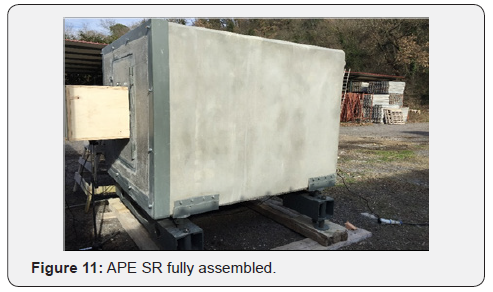

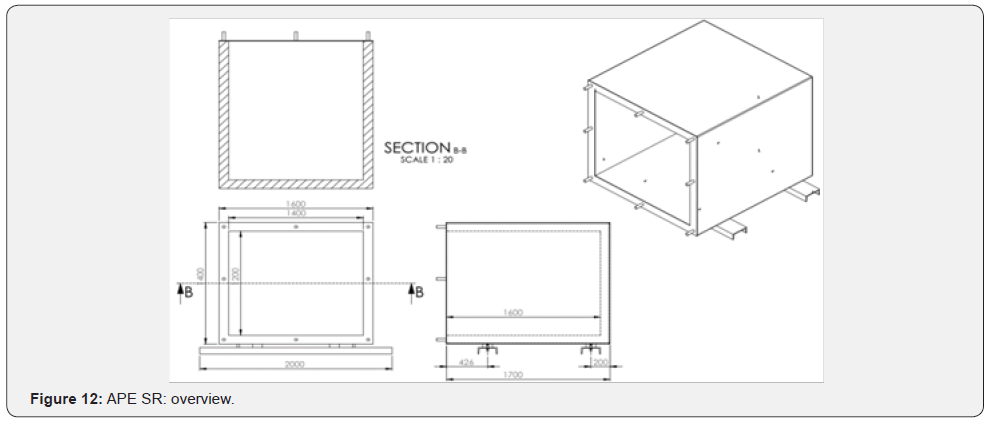

whole assembled structure is shown in the following (Figure 10).

The schematics of the reverberation chamber, excluding the

sample holder and inspection panel, is reported in (Figure 11).

In order to validate the chamber and the measuring system

different materials were used.

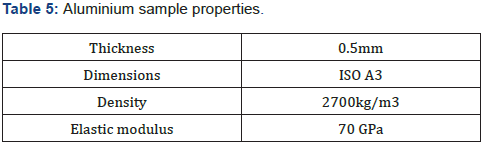

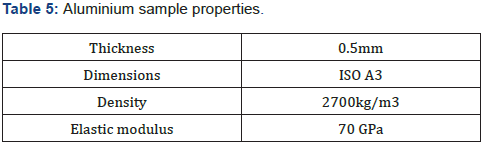

In the case of insertion loss, instead, an aluminium alloy

plate Al 6060, with the following characteristics (Table 5) was

employed:

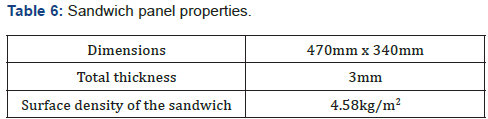

Finally, after chamber validation, measurements of a sandwich

in constrained layer damping configuration, were carried out in

order to assess its acoustic properties. At this regard, the damping

layer was prepared by mixing a Polyethylene Glycol 200g/mol

(Sigma Aldrich) with a 20% by weight of 12nm fumed silica

(Sigma Aldrich), while the outer skins were two plates of Al6060

with a thickness of 0.5mm.

The colloid was prepared by recurring to the following

approach [23]:

i. The powders were dried in an unventilated oven (8h-50

°C).

ii. The powders were dispersed in intermediate carrier

and the resulting slurry was subsequently dispersed in excess

solvent.

iii. The slurry was magnetically stirred at ambient

temperature and then in an ultrasonic bath.

iv. The agglomerates were dispersed in the carrier fluid by

jar-stirring.

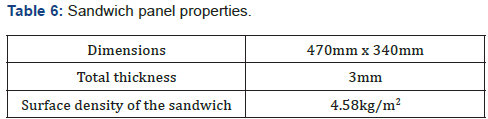

The sandwich used exhibits the following characteristics

(Table 6).

Experimental

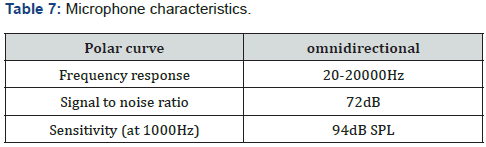

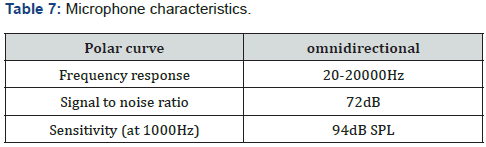

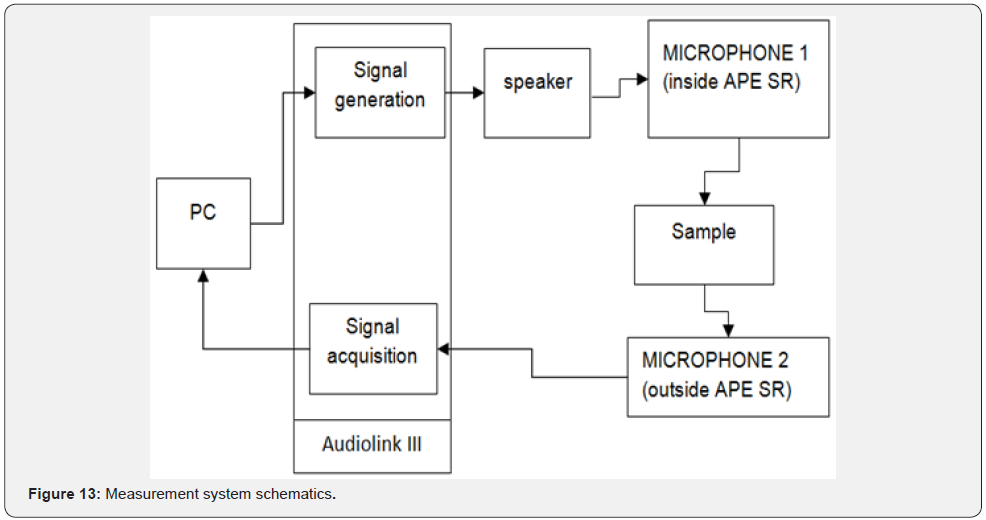

The measurement system annex to the facility and used in

the various acoustical characterisation (insertion loss, absorption

loss) consists of:

i. Two laboratory microphones Super lux ECM 888 B ¼’’

with the following characteristics (Table 7).

ii. An 80-watt speaker with a flat frequency response

(without a prevailing frequency content) between 50Hz and

20000Hz.

iii. A dual mode acquisition card Midtech Audiolink III (two

microphone input-ports and a STEREO or dual MONO audio

output-ports).

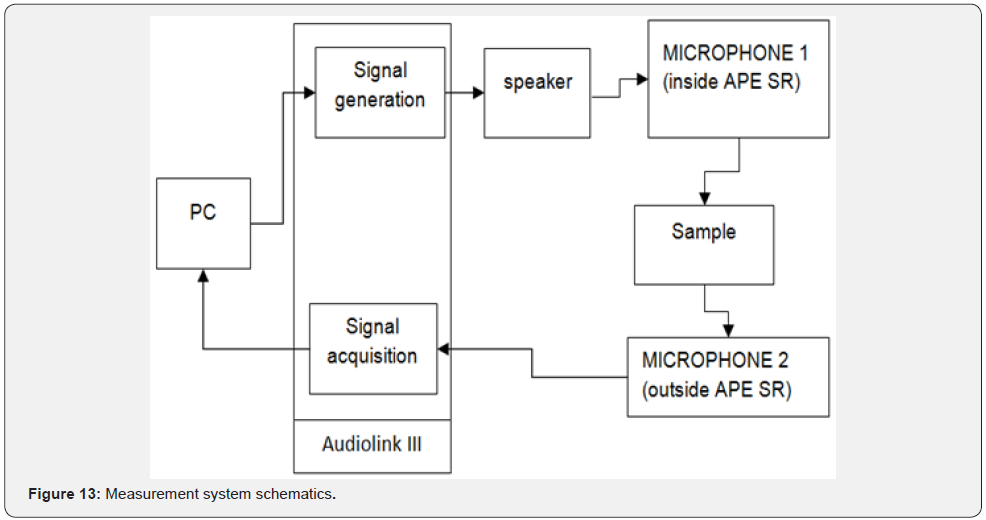

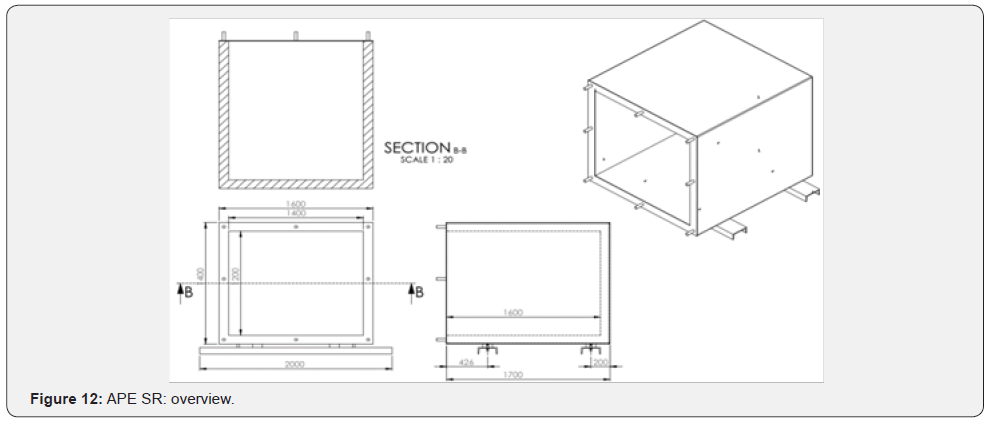

The measurement system (Figure 12) is connected as follows.

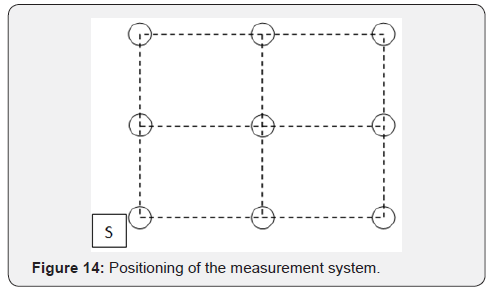

The proposed design of the APE SR reverberation chamber

was validated and compared to the previous analytical results.

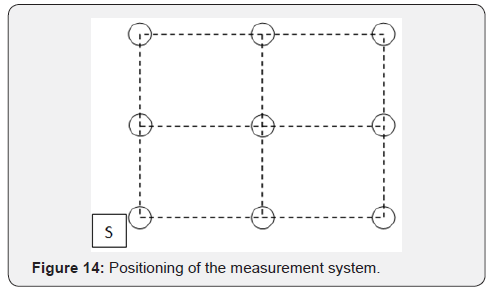

The speaker was located in a fixed position while the microphone

was relocated in 9 different positions (indicated as white circles

in the following Figure 13) in the x-y plane at the same height

z=h/2=1200 mm/2=600mm. During the validation, the sample

holder was momentarily closed with a concrete panel and

completely sealed with a layer of sealant.

The input signal generated was a sine sweep wave with a

linearly variable excitation frequency from 20Hz to 20kHz and

constant unitary amplitude, maintained for 10seconds. The

effective SPL inside the chamber was recorded by the microphone

in each of the 9 configurations and post-processed with the

commercial software Fuzz Measure.

The post-processing is divided into the following phases:

i. Deconvolution of the audio signal, in order to evaluate

the system response to the excitation wave.

ii. Fast Fourier transform (FFT) of the time history data, in

order to evaluate the response in terms of frequency and SPL

[dB].

iii. Evaluation of the actual reverberation time of the

structure and its dependence on frequency.

The Deconvolution is necessary to evaluate the response

of the system to the excitation, in order to filter the signal from

the background noise innate to the measurement system and to

calculate the FFT. This allowed us to evaluate the SPL in 9 different

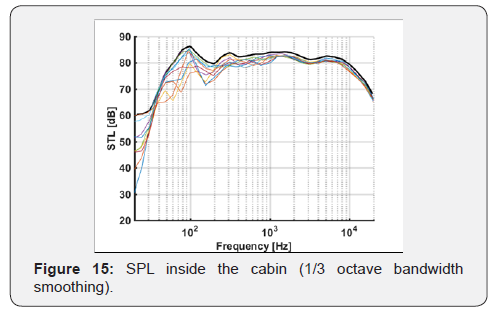

microphone positions (indicated by the thin coloured lines) of the

reverberation chamber.

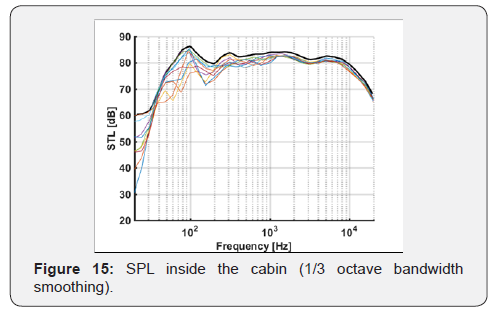

In the following graph (Figure 14), the envelope of the 9 curves

is represented by a bold black line. The signal was smoothed

choosing 1/3 octave bandwidth smoothing (Figure 15).

By observing the data, it can be acknowledged the existence

of a region approximately below 100Hz where the SPL inside the

chamber reaches a minimum. This is caused by the first resonance

of the chamber, which occurs at approximately 106Hz. Before this

frequency there are de facto no reflexions and the sound pressure

level varies significantly from point to point inside the chamber

and assumes low values. Between 100 and 500 Hz the SPL is

highly variable from point to point and the response is highly

dependent on frequency: this is caused by the higher eigenmodes.

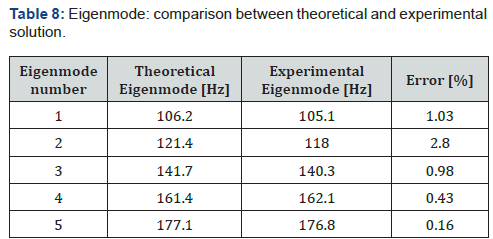

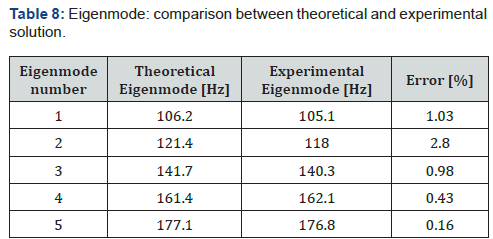

By analysing the envelope of the SPL curved, it is possible

to compare the theoretical eigenfrequencies, calculated by

Helmholtz’s equation, and the experimentally measured ones

(Table 8):

Roughly above 700Hz the SPL envelope curve approximates

a quasi-linear trend and the nine curves tend to coincide. This

phenomenon is an indicator of the fact that the sound power

inside the chamber is almost constant above this frequency. As

a consequence, this signals the passage from a system whose

dynamics are dominated by its modal response to a more desirable

condition of diffused acoustic field.

Also in this case, there is good accordance with the theoretical

value for Schroeder’s frequency. Taking into account that 1000Hz

is the central frequency of the octave bandwidth 710Hz-1420Hz,

we can notice graphically that the diffused field in the APE SR

facility occurs approximately between 700Hz and 1000Hz: this

limit denotes the inferior limit of validity of the successive results

for the STL of the tested samples.

As it can be noticed, between 9000Hz and 20kHz the SPL

decreases, even though it is still maintained the diffused acoustic

field condition. This reduction in the SPL is caused by the microporosities

in the concrete, which act as microscopic Helmholtz

resonators at higher frequencies.

This variation is however limited to 2-3dB up to 15kHz

and, therefore, can be considered negligible. Because of the

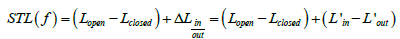

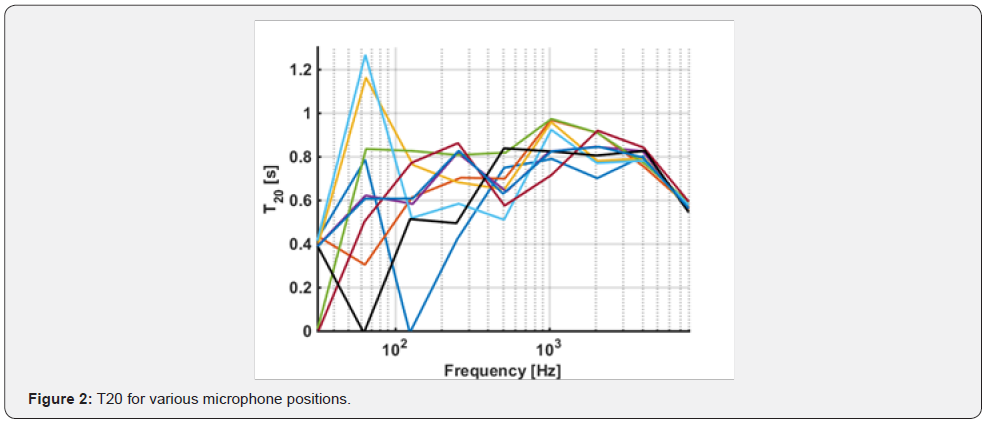

complexity associated with the calculation of the reverberation

time RT60, it was chosen to extrapolate this parameter from the

T20, a conceptually analogous parameter, which is evaluated for an

attenuation of 20dB instead of the 60dB required for the previous

parameter. In fact, in order to calculate the RT60 it is first necessary

to calculate time necessary to have a 60DB attenuation in the

sound energy density D(t) [dB].

However, even though theoretically possible, the calculation

of this value is nontrivial, in particular in small room acoustics

where the dynamic range, nominally the difference between

the maximum value of D(t) and its asymptotic value, is much

smaller than 75dB. This particular value has been demonstrated

empirically [24] to be the threshold value of this parameter

necessary to actually measure and attenuation of 60 dB and

therefore, to evaluate, the RT60. Therefore, according to the norm

ISO 3382, the reverberation time was calculated basing on the

evaluation of a parameter requiring an inferior dynamic range.

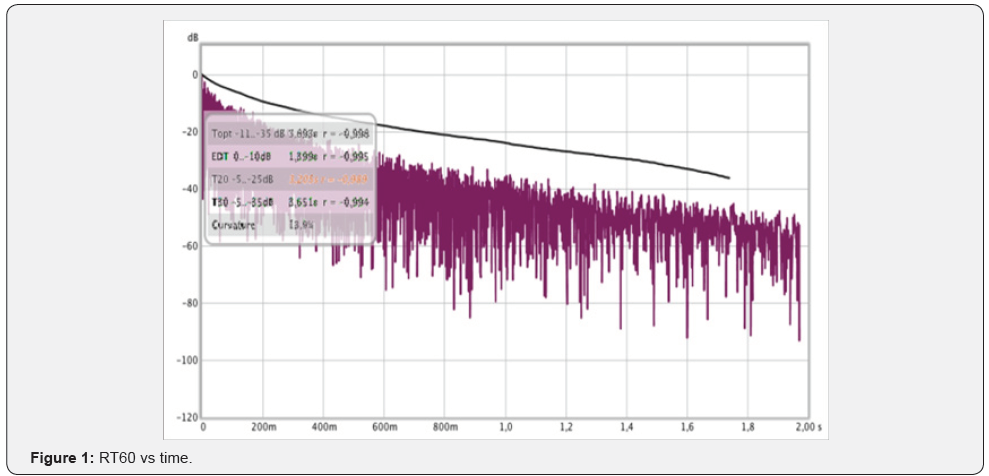

The starting point for the refining of the analysis was the

measurement of D(t)=20 log(h(t)/max[h(t)]) where h(t) is the envelope

of the excitation H(t).

D(t), represented as a thin purple line in the following picture

varies between 0 dB and the value corresponding to the sound

energy density of the background noise.

On the other hand, the Schroeder’s integral

is represented as a bold black line in the graph.

From Schroeder’s integral, it is possible to derive a linear

extrapolation of the reverberation times, by considering a linear

relationship r = A∗t + B ,where A is the slope and B is the

expected attenuation.

Therefore 60 RT = −60 / A, where A is evaluted from the

experimental measurement of the T20.

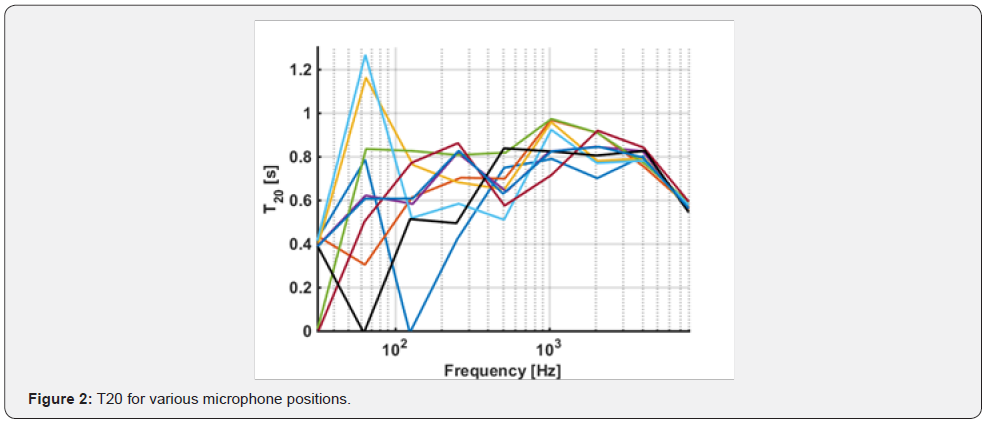

The results for the T20for the various positions of the

microphone at the centre frequency for each octave band width

can be shown in the following graph (Figure 16):

The extrapolated experimental value for RT60 is 2.34s, which

coincides with the value theoretically expected from Sabine’s

formula.

Results and Discussion

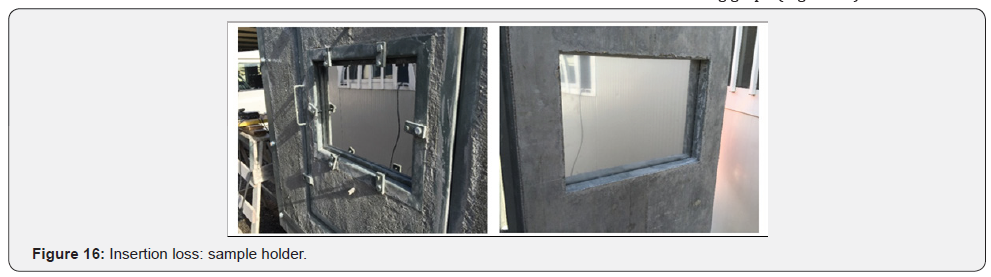

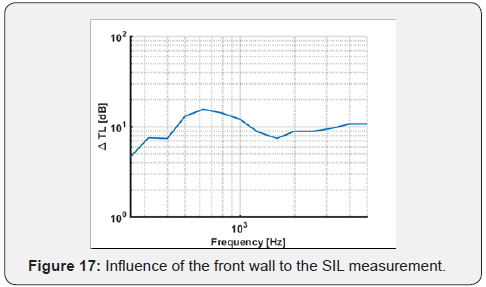

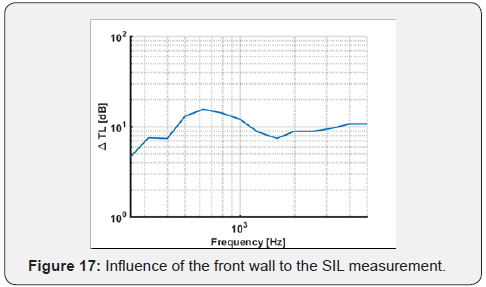

The first step to evaluate the sound transmission loss of

the system was the evaluation of the system in the first two

configurations. The samples were all be tested with the baffled

boundary condition and a white noise signal (a random signal

having a constant power spectral density). This value is an index

of the influence of the closing wall to the sound pressure level

effectively perceived by the sample (Figure 17). The results with a

1/3 of octave bandwidth smoothing showed that this value attests

at around 10dB after the diffused field condition is established.

This parameter is extremely relevant in the case of the APE SR,

because of the reduced size of the sample holder, which causes a

non-negligible boundary effect contribution to the IL.

For the proposed design, the minimum sample dimension

was reduced to a ISO A3 standard, much smaller than the 6m2

required for traditional transmission loss testing and therefore

this parameter is non-negligible to the system response. Once the

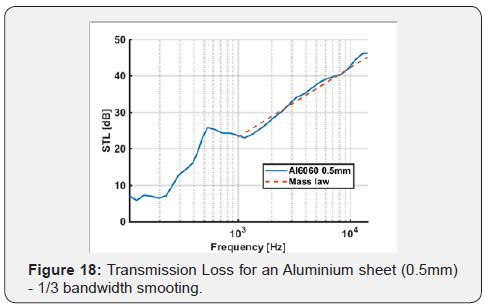

system was set, it was possible to compare the numerical expected

results for a simple system, whose vibroacousticresponseis widely

known in the currently available literature (i.e. aluminium plate)

with the measured ones.

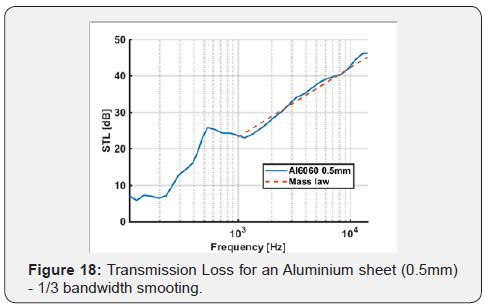

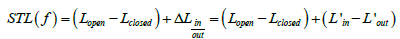

As it can be seen (Figure 18), the experimental results are

adherent to the theoretical ones in the diffused field region, as

expected. We can therefore consider the system fully validated

and we can consider reliable the results for our measurements

between 700 and 15000Hz. Below 700Hz, as previously discussed,

there is a highly instable zone characterized by the presence of

both the modal response of the chamber and of the resonance of

the material.

However, it is still possible to identify the stiffness-controlled

zone of the response of the system at approximately 100Hz and

the damping-controlled zone between 200Hz and 1000Hz, as

expected by the theoretical results [25-28].

With the fully validated system, the same analysis was

repeated, as a proof of concept, for a sandwich structure in

constrained layer damping configuration, realized as previously

described in the Materials section. First of all, we carried out the

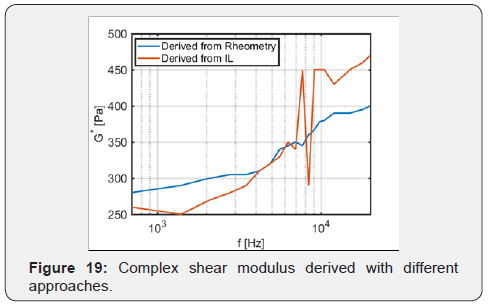

rheological analysis of the nanocomposite previously described,

by recurring to the following rheological approach.

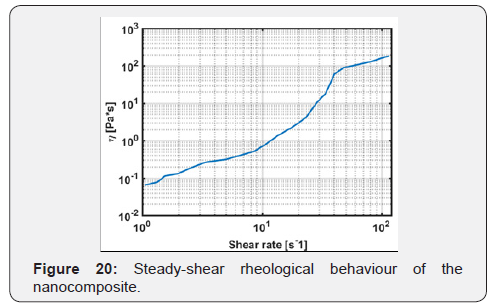

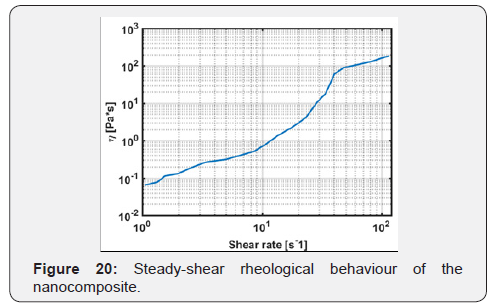

We carried out an steady-shear rheological measurement

with a Strain-controlled rheometer (Kinexus LabPro+). The

chosen fixture was a conical plate with a 0.8mm gap between the

sample and the lower end of the fixture. A 1 minute 1s{ 1} − shear

rate was applied to each sample (25ml), to break-pre-existing gel

structures and therefore, to be able to neglect pre-existing stress

fields in the fluid. The shear strain varied between 1 % and 120

%. This allowed us to pre-screen the properties of the fluid that

exhibits a shear-thickening Non-Newtonian behavior (Figure 19).

However, as these materials are rheologically complex and do

not obey to Delaware-Rutgers’ rule [29], to fully model the acoustic

constitutive behavior of this material requires further research.

Furthermore, Time-temperature superposition techniques, such

as WLF, generally provide unreliable constitutive behavior at

higher frequencies [30,31].

In order to fully model and analyse the vibroacoustic response

of the sandwich at acoustic frequencies and the dependence on

the composition of the nanocomposite, further investigation is

required for the rheological response of the polymer at acoustic

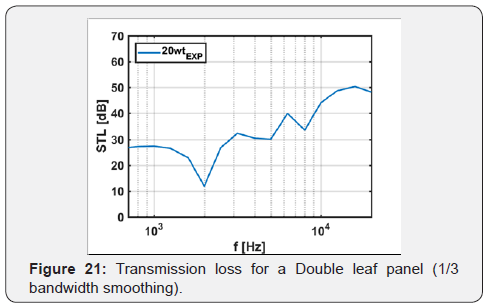

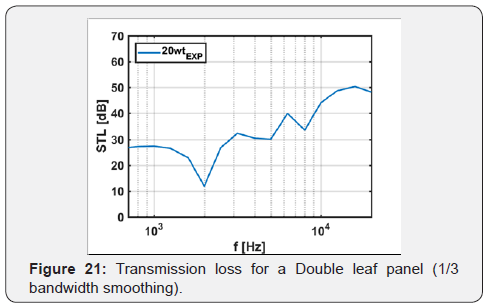

frequencies [1,32]. By iterating the Insertion loss measurement

method reported above, it was possible to calculate the sound

insulation properties for the proposed sandwich material (Figure

20 & 21):

Between 2200Hz and 10000Hz shows a step increase in the

STL, before experiencing a progressive decrease in the sound

insulation properties. This is caused by the high-frequency

response of the proposed material composing the constrained

damper [7,33-36]. The decrease in the STL of the sandwich can

be ascribed to the reduction in the damping of the core at higher

frequencies, which occurs in the sandwich nearby the coincidence

frequency. In this range its response is actually dominated by the

damping of the system, in accordance with the previous results.

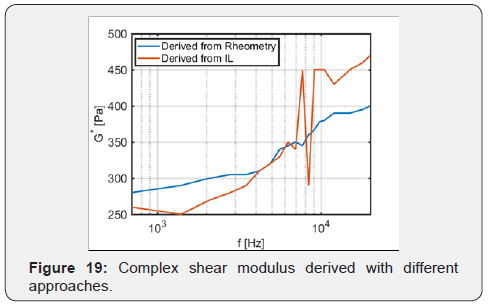

Finally, the complex shear modulus can be derived from the

STL. In both cases, as typically expected for STFs, the complex

shear modulus increases with frequency. As a comparison, the

results for the numerical extrapolation proposed in [23] are

compared with the ones extrapolated from equation 1 in (Figure

19). The linearly extrapolated shear modulus provides a good

matching with nonlinearly extrapolated one for lower frequencies.

However, the values tend to deviate from one another as the

frequency increases. This can be traced back both to errors in the

non-linear regression and in the experimental measurement, that

tend to increase at higher frequencies. Further research is due.

Conclusion

The objective of this work was the development of a empirical

approach to evaluate the rheological behaviour of smart materials.

This method required the design of a small acoustic research

facility, optimized for laboratory environments and quality

assurance laboratories.

The structure was designed as a flexible tool, usable for

the evaluation of the sound insulation of innovative composite

materials in diffused sound field conditions, which cannot be

achieved in conventional acoustic laboratory equipment such

as impedance tubes there are standard test methods for the

determination of these properties. There is, however, no standard

for the equipment used in these tests, only a specification for

the test conditions. The objective of this work was to evaluate

the operation and performance of a bench top laboratory sound

testing system for its potential as a simple cost effective method

for the initial evaluation of materials that require specific acoustic

properties. The work was limited to an investigation of the

property of sound transmission loss (STL(6)(6)(5)(5)(6)(6)(6).

As a consequence, the structure was designed taking into

account:

i. The maximisation of the stiffness to weight ratio of the

structure and its movability

ii. The reduction of the required dimension of the samples

(from 6m2 to an ISO A3).

iii. The maximisation of the frequency ranges of analysis, up

to 700Hz-15000Hz.

The reverberation chamber, built in reinforced concrete

according to these guidelines, was validated by testing the

insertion loss of an aluminum alloy plate Al 6060. The achieved

results showed a good agreement with datasheets of investigated

samples.

Further experimental tests demonstrated the potential

use of the chamber to assess the vibroacoustic behavior of

structures comprising smart materials. At this regard, preliminary

measurements carried out on a system constituted by aluminum

skins and a core including fumed silica nanoparticles highlighted

interesting perspectives of the new acoustic facility to investigate

nano structured systems that can be used as damping materials

as well as its actual reliability. Finally, the complex shear modulus

extrapolated from acoustical data was compared with the one

obtained by means of non-linear regression of rheological data

from low-frequency data.

For more

details Academic

Journal of Polymer Science please click on: https://juniperpublishers.com/ajop/index.php

To read more…Full Text in Juniper Publishers click on https://juniperpublishers.com/ajop/AJOP.MS.ID.555557.php

Comments

Post a Comment